最適な品質

CGM Polyhedraは、多面体モデルをチェック、修復、編集、照会するためのAPIを提供し、アプリケーションの要件を満たすことを保証します。CGM Polyhedraのアルゴリズムは、最大規模のデータセットに対しても、ロバストで高性能なモデリング操作を提供するように設計されています。

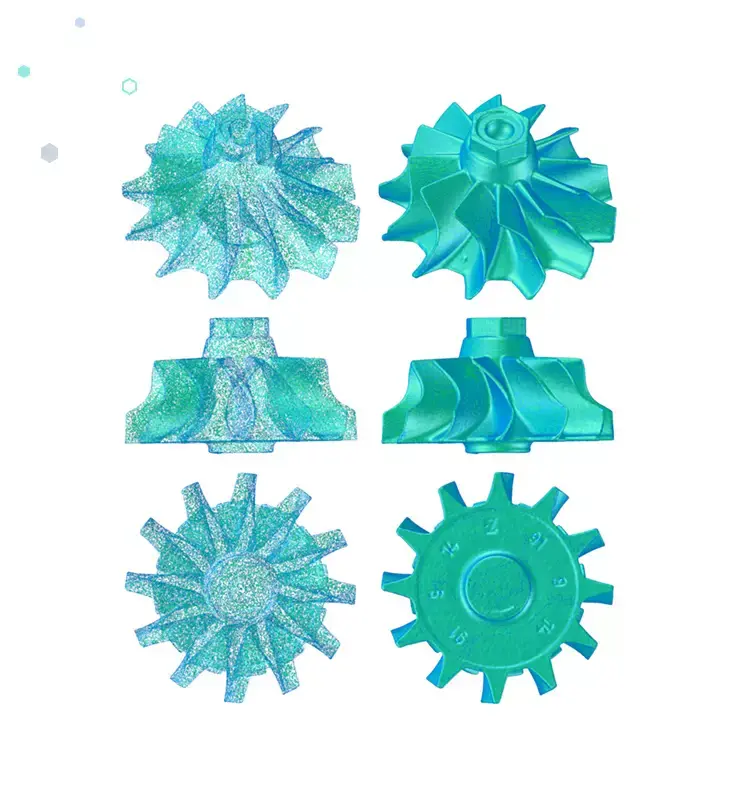

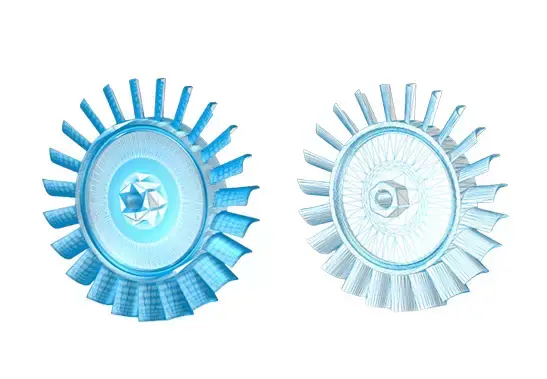

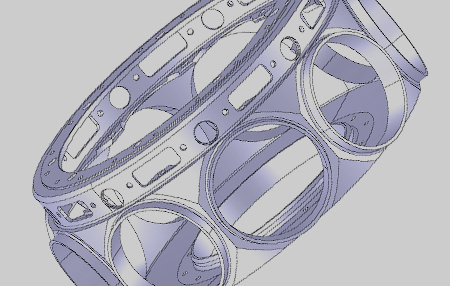

CGM Polyhedraで、3Dアプリケーションの精密な多面体モデリングのパワーを引き出しましょう。設計、製造、シミュレーションといったアプリケーションが進化するにつれ、従来のCADベースのシステムは、メッシュベースのワークフローのサポートが求められてきています。医療や鉱業のような業界では、大規模なデータセットを高いテッセレーション品質で堅牢に処理することが求められます。CGM Modelerおよび3D ACIS Modelerとシームレスに統合されたCGM Polyhedraは、高精度モデリング機能を拡張し、アプリケーションが新しいワークフローに対応し、革新的な製品やソリューションを顧客に提供できるようにします。

CGM Polyhedraは、多面体モデルをチェック、修復、編集、照会するためのAPIを提供し、アプリケーションの要件を満たすことを保証します。CGM Polyhedraのアルゴリズムは、最大規模のデータセットに対しても、ロバストで高性能なモデリング操作を提供するように設計されています。

CGM PolyhedraのAPIを活用することで、積層造形のデータ準備など、新しいワークフローを迅速にアプリケーションに追加でき、時間と開発コストを節約できます。

次世代3Dアプリケーションのための究極のモデリング技術。CGM Modelerで3Dデータの作成、修正、クエリ、可視化を実現。

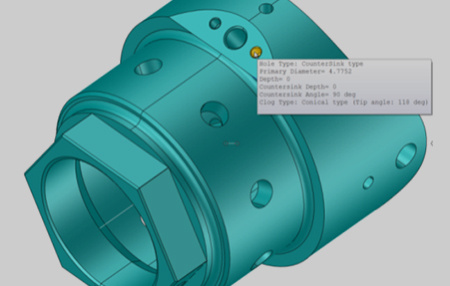

穴やフィレットなどのフィーチャ除去をユーザー入力なしで行うことで、アプリケーションの自動化を実現。

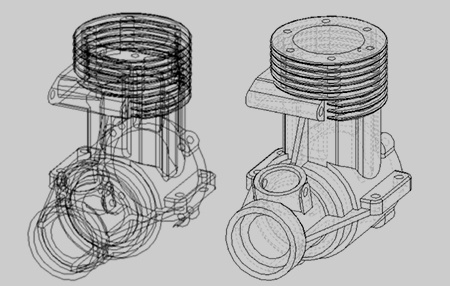

様々な視点から3Dモデルの可視線、隠線、シルエット、遮蔽部を計算し、理解しやすい図面データを生成。

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

Discover how your 3D application can allow seamless, iterative collaboration between multiple users with CAD Associativity.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

Discover how your 3D application can allow seamless, iterative collaboration between multiple users with CAD Associativity.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Explore scenarios for Additive Manufacturing OEMs to offer complete solutions, impacting revenue and margins.

Discover Automatic CAM, the enabling processes, and its application benefits.

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Explore scenarios for Additive Manufacturing OEMs to offer complete solutions, impacting revenue and margins.

Discover Automatic CAM, the enabling processes, and its application benefits.

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.