应用程序的最高质量

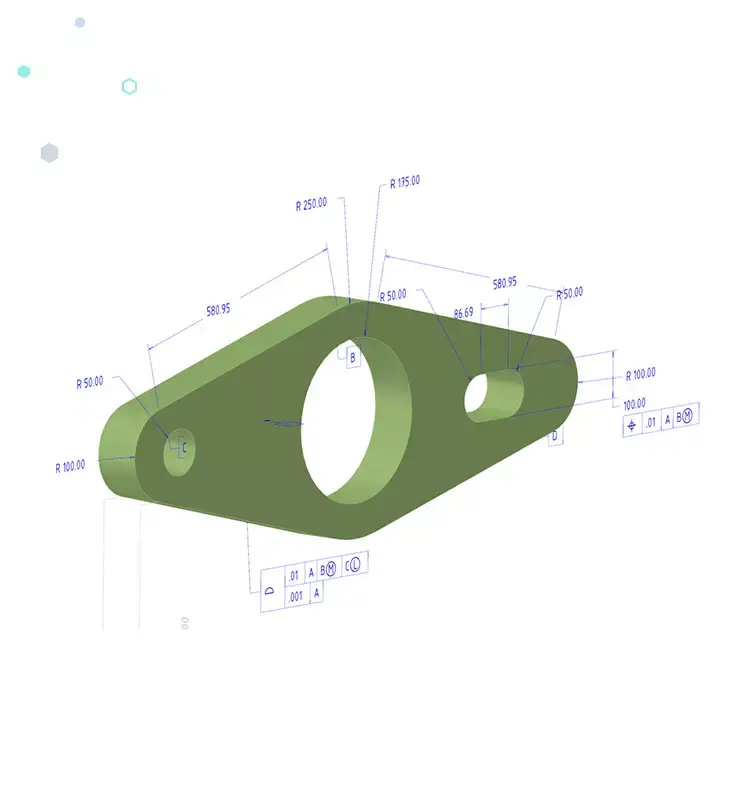

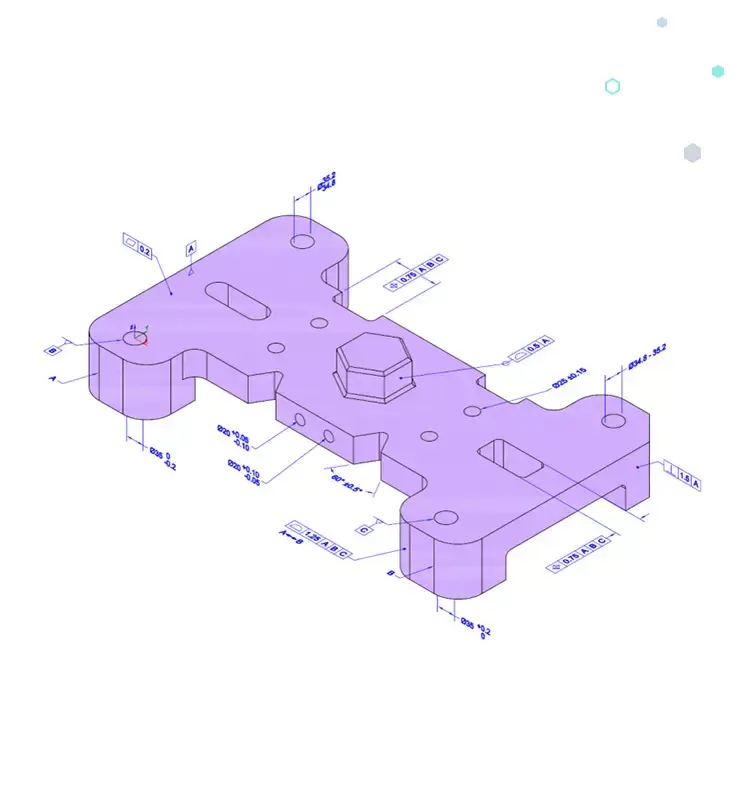

3D InterOp 为 ACIS、CGM 和 Parasolid 生成原始几何体,提供高质量的数据,并确保下游操作的成功。减少或消除这些下游数据的问题可以提高用户生产率并降低风险。

3D InterOp 是业界领先的 3D CAD 数据转换软件开发工具包,旨在交换各种CAD格式的可视化、精确的B-rep几何图形和元数据。

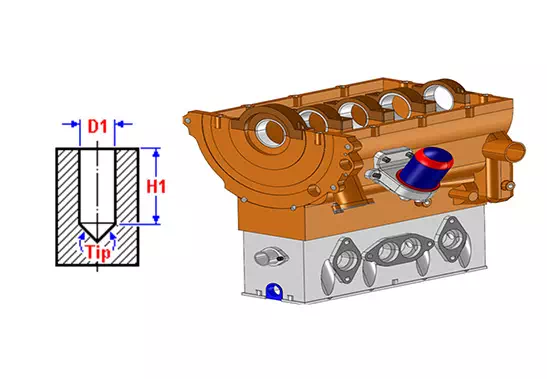

它使您的客户能够像在自己的应用程序中本地创建一样来使用导入的CAD数据,并为下游工程应用程序导出数据。3D InterOp 的架构使用户能够优化与 2D 和 3D 数据的交互。它支持领先工程应用程序所需的所有主要 3D/CAD 数据交换格式之间的文件共享,以及任何建模器(包括 3D ACIS Modeler、CGM Modeler 和 Parasolid)的 CAD/CAM 数据交换。

利用 3D InterOp 的开发人员受益于300 多家公司 20 多年来验证的解决方案。

3D InterOp 为 ACIS、CGM 和 Parasolid 生成原始几何体,提供高质量的数据,并确保下游操作的成功。减少或消除这些下游数据的问题可以提高用户生产率并降低风险。

在需要时通过导入您选择的容器加载数据,来提供最佳的用户体验。3D InterOp 的选择性加载功能允许增量导入 CAD 数据,包括产品结构、镶嵌几何图形、精确几何图形和制造信息。

3D InterOp 每年发布两个主要版本,每周更新次要版本,确保以最快的周转时间支持更新的格式版本。CATIA V5 和 SolidWorks 的格式持续更新,涵盖了行业内交换的约 50% 的 CAD 模型。

包括设计、工程、制造、机器人和计量在内的各个领域的主要行业参与者都信任3D InterOp来满足他们的互操作性软件需求。凭借 Intergraph、卡尔蔡司、ANSYS 和西门子等客户,3D InterOp 已在各个行业的应用中得到了验证。

除了几何图形外,3D InterOp 还可导入相关元数据,实现应用程序工作流程自动化。通过导入制造信息等数据,3D InterOp 已成为多个行业数百万用户的既定解决方案。

Spatial 始终与客户保持着良好的联系,根据反馈和支持需求不断推动 3D InterOp 的发展。通过定期的修补程序和重大更新,Spatial 可确保客户及时获取问题的解决方案和最新 CAD 版本的支持。

除了我们的支持和服务人员提供的专家指导外,3D InterOp 还提供了 C++/C# 接口和示例实现的完整文档。基于 JavaScript 的应用程序 (3DScript) 也可用于快速原型制作和调试。这种全面的支持使客户能够快速集成和使用 3D InterOp,从而实现成功部署。

| 格式 | 读取 | 写入 |

| Navisworks | • | |

| 3DXML | - | - |

| 3MF | - | - |

| ACIS | • | - |

| AVEVA | - | |

| CATIA V4 | - | - |

| CATIA V5 | - | - |

| 3dexperience(CATIA V6) | - | |

| COLLADA | • | |

| DXF / DWG | - | |

| glTF | - | |

| FBX | - | • |

| IFC | - | - |

| IGES | • | - |

| Inventor | - | |

| JT | - | |

| MicroStation | • | |

| NX | • | |

| OBJ | • | |

| Parasolid | - | - |

| Pro / E / Creo | - | |

| Revit | - | - |

| Rhino | - | |

| Smart3D | - | |

| Solid Edge | - | |

| SOLIDWORKS | - | |

| STEP | • | - |

| STL | - | - |

| VDA-FS | - | - |

| XCGM | - | • |

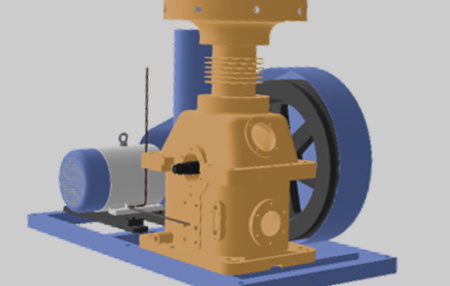

通过模型简化、特征提取、几何优化和装配管理,为仿真、制造和可视化准备CAD数据。

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

Discover how your 3D application can allow seamless, iterative collaboration between multiple users with CAD Associativity.

LK Metrology致力于保持其坐标测量机的精度。通过与Spatial的开发合作,他们提升了核心应用功能。

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

Discover how your 3D application can allow seamless, iterative collaboration between multiple users with CAD Associativity.

LK Metrology致力于保持其坐标测量机的精度。通过与Spatial的开发合作,他们提升了核心应用功能。

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

FVA的解决方案服务于传动系统行业,其软件能够进行复杂仿真和变速箱组件的详细分析。

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

FVA的解决方案服务于传动系统行业,其软件能够进行复杂仿真和变速箱组件的详细分析。

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

-import-from-CAD.jpg?width=1440&name=Let-CAD-drive-Manufacturing---Product-Manufacturing-Information-(PMI)-import-from-CAD.jpg)