Remove Unnecessary Features for Faster Preparation

Revolutionize your CAD model simplification with CGM Defeaturing, an innovative SDK add-on from CGM Modeler.

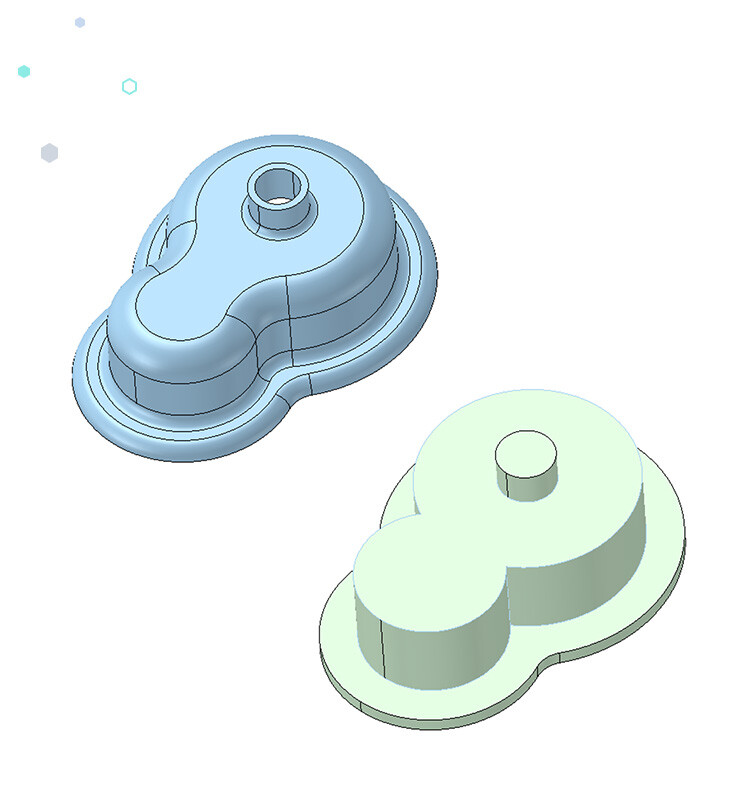

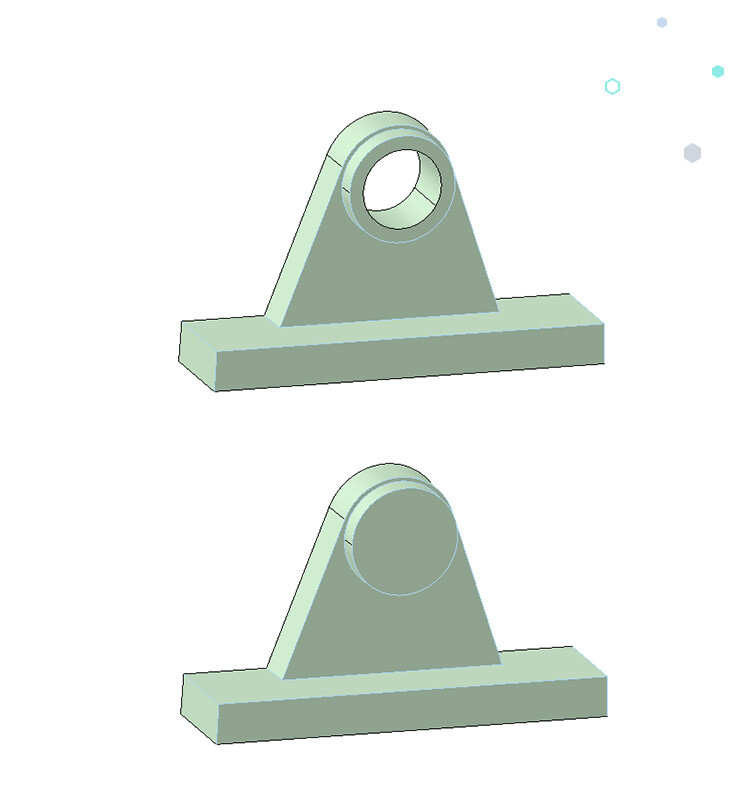

CGM Defeaturing is designed to identify and remove features from CAD models to achieve the right level of detail for visualization, design, manufacturing or simulation.

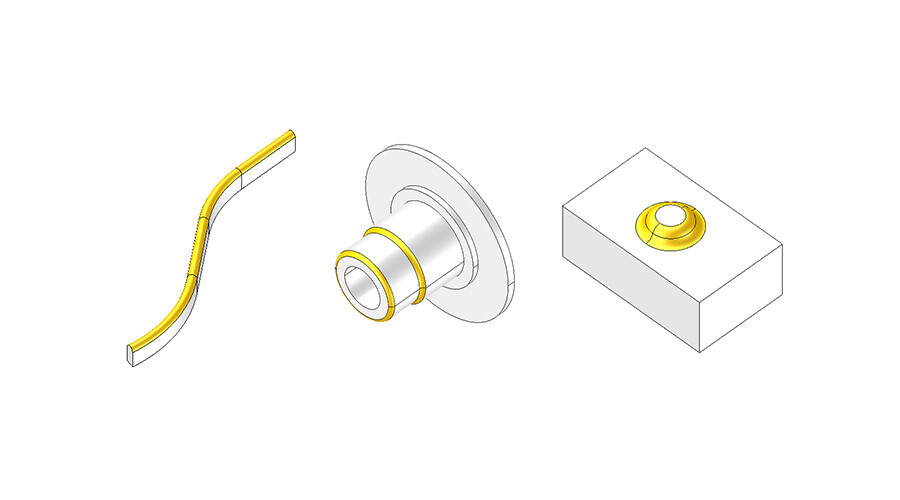

Application developers can use feature recognition and face removal to build smart defeaturing workflows such as eliminating specific hole types, including counterbore holes, countersunk holes, through holes, blind holes and more.

This automation simplifies the model and enhances the performance of various downstream processes. With CGM Defeaturing, you can achieve faster, more efficient workflows and superior end results, transforming your ideas into reality with unmatched precision and ease.