What Is AGM?

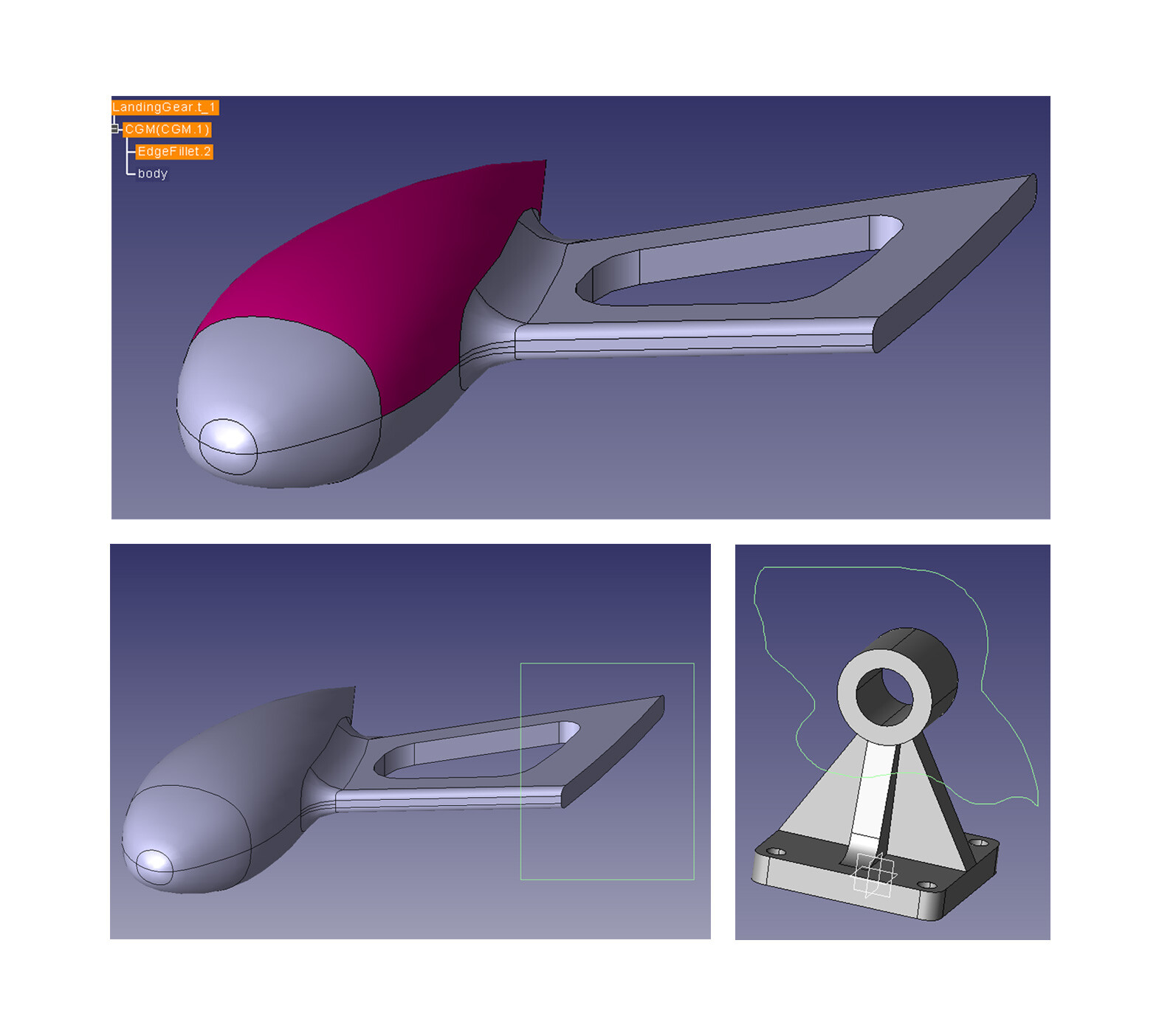

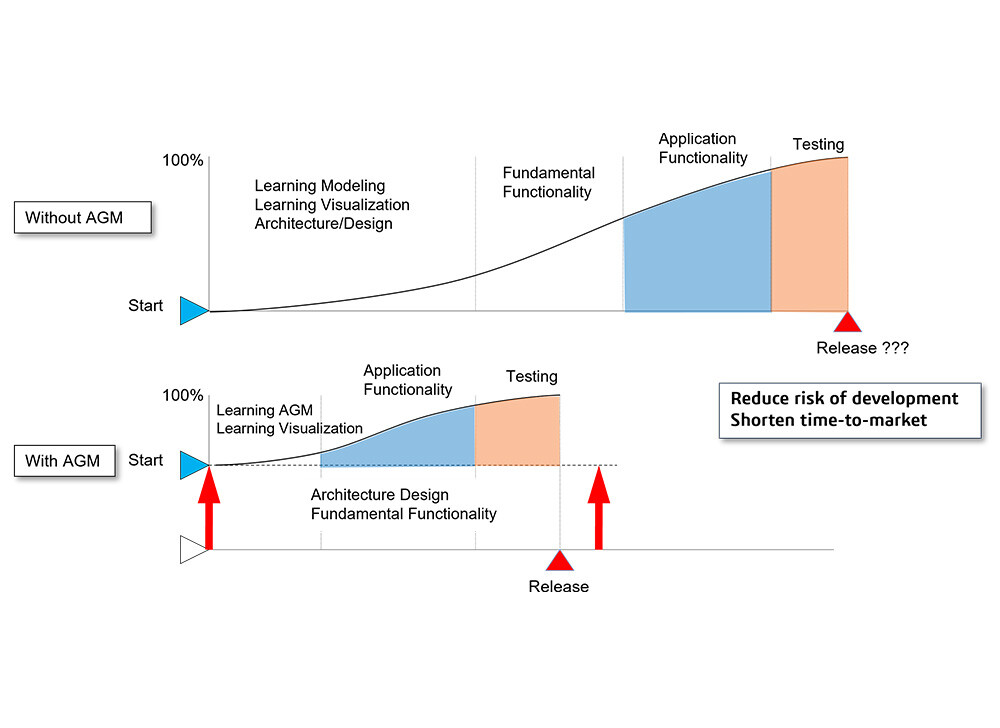

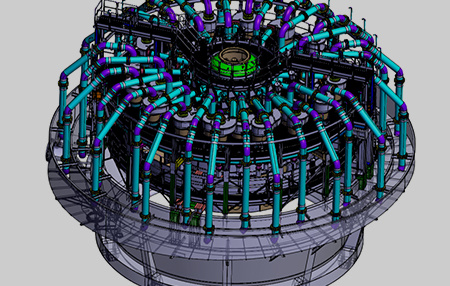

AGM is a 3D application framework and starter application designed to facilitate the development of robust 3D applications for design, engineering, simulation and manufacturing. It offers an out-of-the-box solution that includes all the necessary source code, training, and project files to easily integrate Spatial’s 3D SDKs for data exchange, geometric modeling, meshing for simulations and visualization. AGM allows Spatial’s customers to quickly jumpstart development for both desktop and web applications.

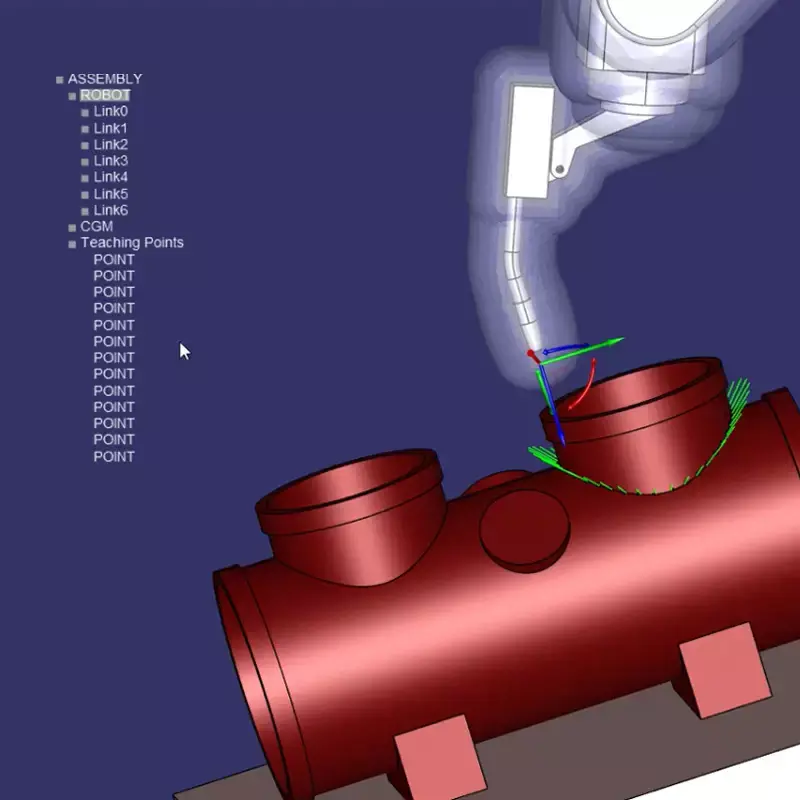

AGM is built on a solid infrastructure that supports various functionalities such as selection and highlighting, undo/redo mechanisms, error handling, and file save/restore processes. It also includes advanced features like fast collision detection and 3D visualization.

AGM has been developed over twenty years and has been the backbone for more than forty applications released worldwide. AGM is more than just a development tool – it's your gateway to accelerated innovation in the world of 3D applications for design, engineering, simulations and manufacturing.

-3D-Printing-Demo.jpg?width=1440&name=Application-Graphics-Manager-(AGM)-3D-Printing-Demo.jpg)

.jpg?width=1440&name=Application-of-Arc-Welding-in-Application-Graphics-Manager-(AGM).jpg)

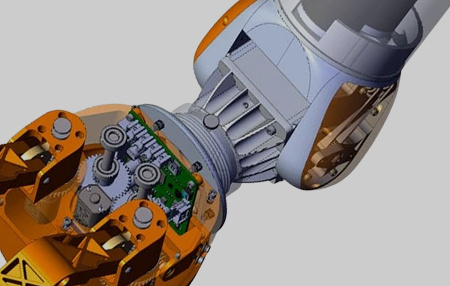

-for-robotics-applications-using-Spatial-SDKs-in-AGM.jpg?width=1440&name=Collision-detection-(near-miss)-for-robotics-applications-using-Spatial-SDKs-in-AGM.jpg)

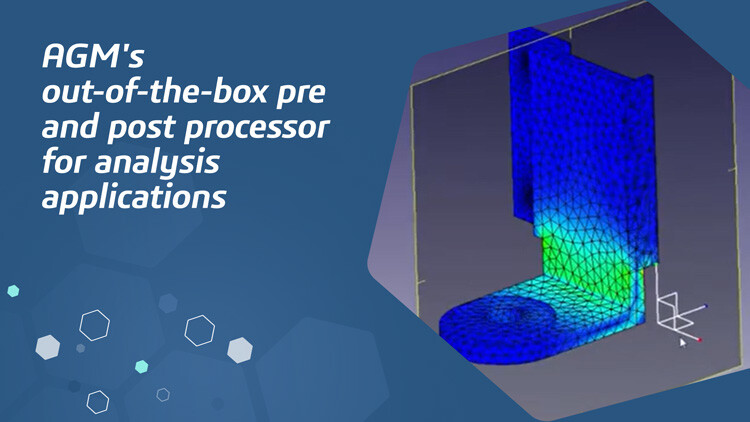

-Post-Processing-in-the-Application-Graphics-Manager-(AGM).jpg?width=1440&name=Computer-Aided-Engineering-(CAE)-Post-Processing-in-the-Application-Graphics-Manager-(AGM).jpg)

.jpg?width=1440&name=Sketcher-Feature-in-the-Application-Graphics-Manager-(AGM).jpg)