三维建模

我们很自豪能够与 ACIS 一起率先开发几何内核。如今,我们提供的解决方案可满足您的三维几何表示需求。无论您需要连续还是离散的 B-Rep 建模器,我们都能为您的特定应用需求提供解决方案。

更多信息Spatial's 3D InterOp dramatically reduces data translation errors and ensures the highest quality data exchange from STL to CAD formats, speeding up workflows and lowering project costs.

Spatial's 3D InterOp tools make it possible:

STL is one of the most widely used 3D model file formats, with widespread support for 3D files and printers.

STL has become a popular format in the prototyping and 3D printing fields because it is virtually universal in terms of printer support and software compatibility.

However, converting between formats can easily lead to errors.

The unusual nature of the STL format creates unique challenges during data exchange that can lead to project delays and cost overruns.

But Spatial's 3D InterOp tools perform STL repair and data conversion seamlessly, giving you high-quality results right the first time.

With support for many competing CAD file formats and a wide range of 3D printers, having a tool that allows you to quickly and seamlessly bring in 3D data can make a big difference in your workflow.

The 3D InterOp component supports all major data exchange formats and converts them into the appropriate format that works with all downstream engineering applications.

In addition to its robust conversion capabilities, Spatial also includes advanced technology for automatic repair of file formats such as STL, allowing for geometry and topology repair.

Poor quality data conversion is a costly problem.

Data imperfections can compromise design intent, leading to printing and production delays and project maintenance costs, as well as post-manufacturing defects that don't become apparent until later in the product cycle.

3D InterOp significantly reduces costs by preventing translation errors and ensures high-quality data exchange that fully supports design intent.

With its convenient plug-and-play architecture and wide range of supported formats, 3D InterOp allows you to quickly add STL to CAD converters and translators to your applications with minimal code edits.

This easy scalability enables faster workflows, more efficient conversions, and increased productivity.

And because it's fully integrated with other Spatial modeling kernels, such as CGM Core Modeler, 3D InterOp can dramatically reduce delays associated with cross-platform compatibility.

Spatial 3D InterOp is the powerful data conversion tool you need to enable fast, high-quality, cost-effective CAD project workflows.

It provides unparalleled 3D data reuse and import capabilities, high-quality multi-format conversion, automatic repair, geometry and topology healing, and other essential features you need to make your project a success.

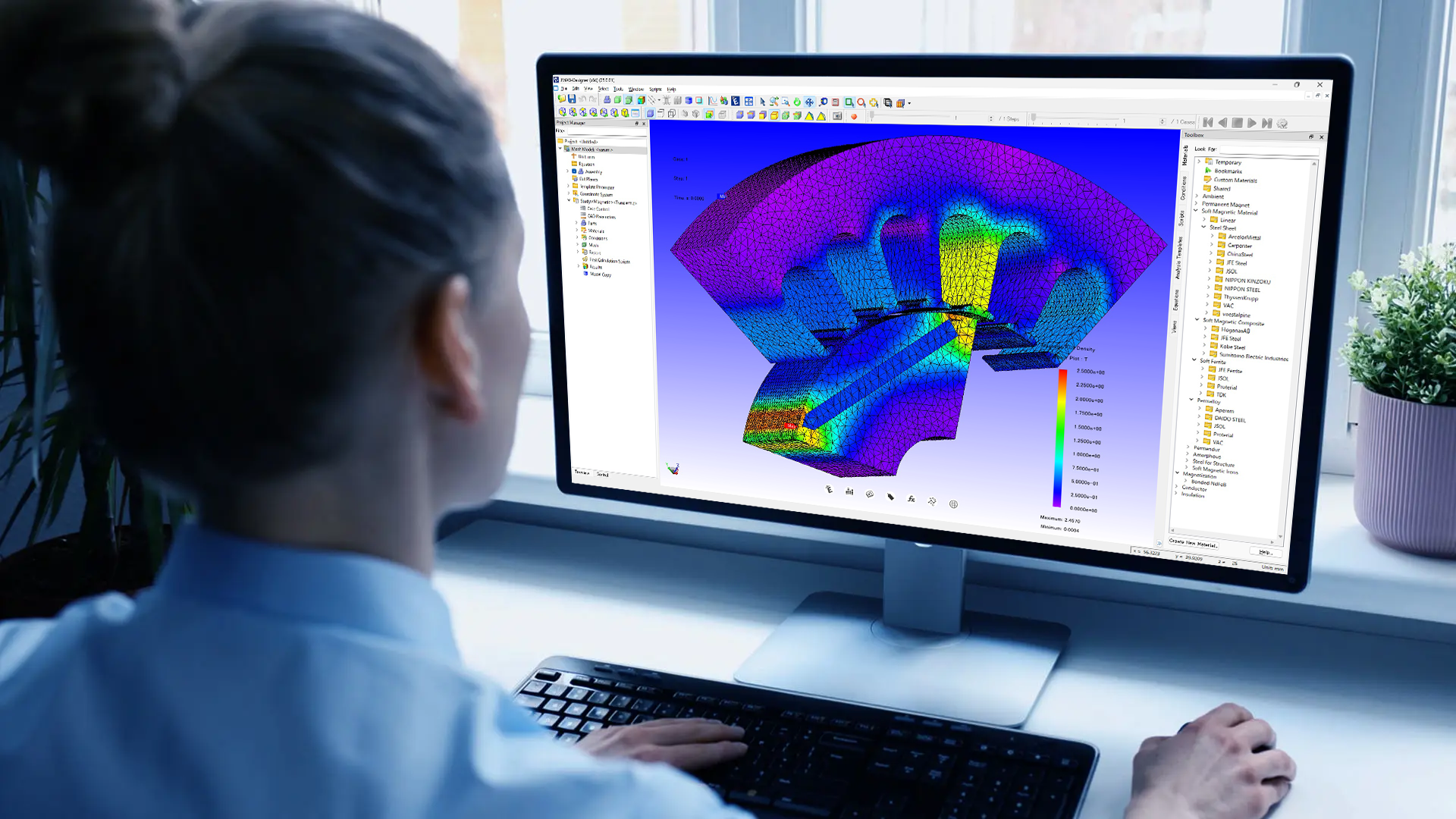

JMAG是由JSOL CORPORATION开发的用于机电设计的仿真软件,它需要具备3D几何体处理、可靠的跨多种格式CAD导入、交互式操作和缺陷控制功能。

COSCOM 需要一种高效的解决方案来管理其数字孪生应用程序中的大量 CAD 数据,同时保持 CNC 加工过程中碰撞检测和机器仿真的精度。

Treble Technologies 通过集成 Spatial 的 Meshing SDK 加速了其仿真流程,从而能够以更快的速度进行大规模的高保真声学仿真。

Simus Systems 需要一个 CAD 格式接口,以便将其数据处理和成本核算软件迁移到云端。

知名CAD内容供应商TraceParts在其在线3D零件查看器中集成了强大的3D可视化功能,以提升客户订购体验。

COSCOM 需要一种高效的解决方案来管理其数字孪生应用程序中的大量 CAD 数据,同时保持 CNC 加工过程中碰撞检测和机器仿真的精度。

Treble Technologies 通过集成 Spatial 的 Meshing SDK 加速了其仿真流程,从而能够以更快的速度进行大规模的高保真声学仿真。

Simus Systems 需要一个 CAD 格式接口,以便将其数据处理和成本核算软件迁移到云端。

知名CAD内容供应商TraceParts在其在线3D零件查看器中集成了强大的3D可视化功能,以提升客户订购体验。

为机床供应商提供的三部分指南,内容涵盖如何通过软件差异化提升硬件销售,以及如何选择合适的开发工具包。

一本介绍应用程序生命周期管理、其选项以及它如何增强应用程序的电子书。

了解模型修复和验证、其对建模操作的影响以及详细的测试结果。

Learn about the best CAD file interoperability solutions, the importance of accurate data exchange, and applications in design, analysis, manufacturing, and measurement.

为机床供应商提供的三部分指南,内容涵盖如何通过软件差异化提升硬件销售,以及如何选择合适的开发工具包。

一本介绍应用程序生命周期管理、其选项以及它如何增强应用程序的电子书。

了解模型修复和验证、其对建模操作的影响以及详细的测试结果。

Learn about the best CAD file interoperability solutions, the importance of accurate data exchange, and applications in design, analysis, manufacturing, and measurement.