作为 AR/VR 软件开发团队、

您可能会关注

简化复杂的 CAD 模型

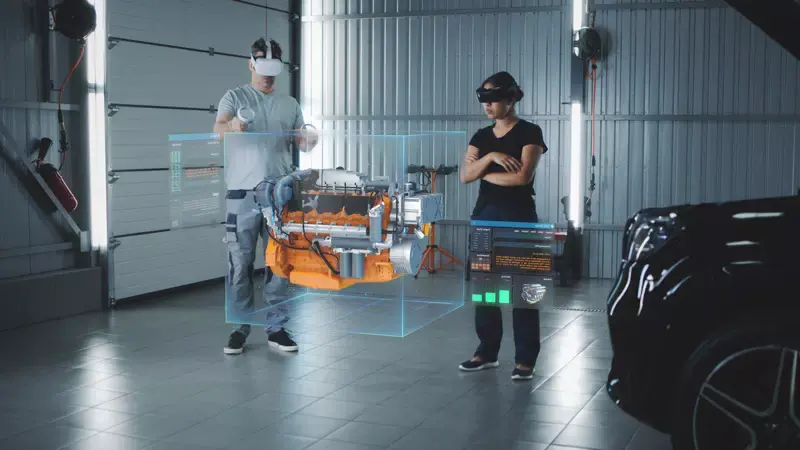

为 AR/VR 优化 CAD 模型,同时不丢失关键细节,确保在沉浸式环境中的可用性。平衡性能和视觉质量

创建有效的细节级别(LOD),在提供逼真视觉效果的同时保持高性能。确保

兼容性

支持各种 CAD、AEC/BIM 格式和硬件平台,实现无缝集成。

优化

三维内容

准备和增强 3D 网格模型,以改进 AR/VR 应用程序中的工作流程和协作。

应对 AR/VR 挑战

利用Spatial解决方案

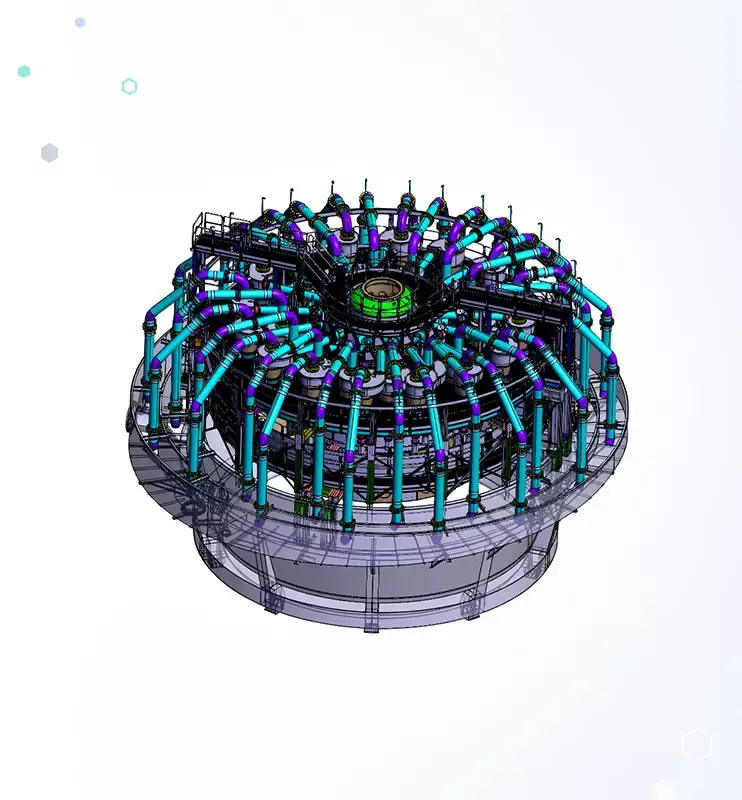

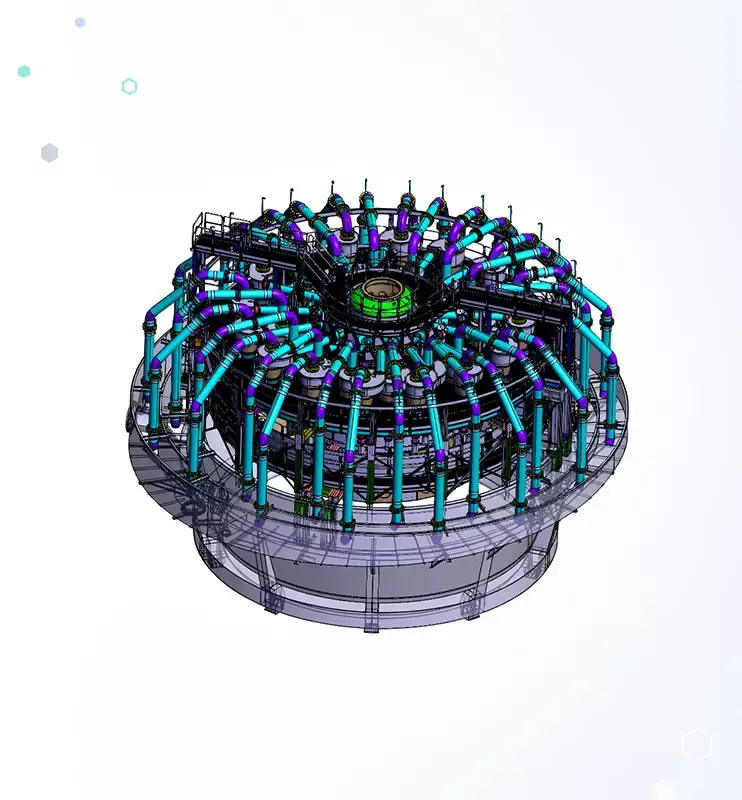

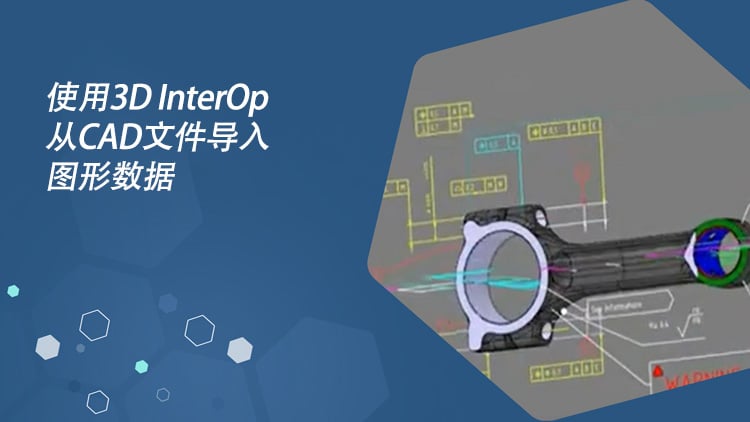

快速导入大型组件

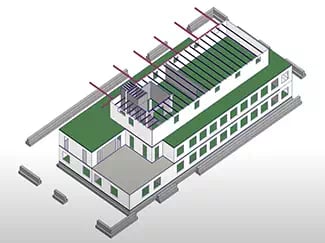

3D InterOp 支持专业的 CAD 导入、B-rep 几何处理和非精确几何。除了导入超过 25 种不同的 CAD 和网格格式外,3D InterOp 还支持 AEC/BIM 格式。3D Interop 支持各种元数据,包括材料、颜色和产品制造信息,从而增强了制造 xR 工作流程。

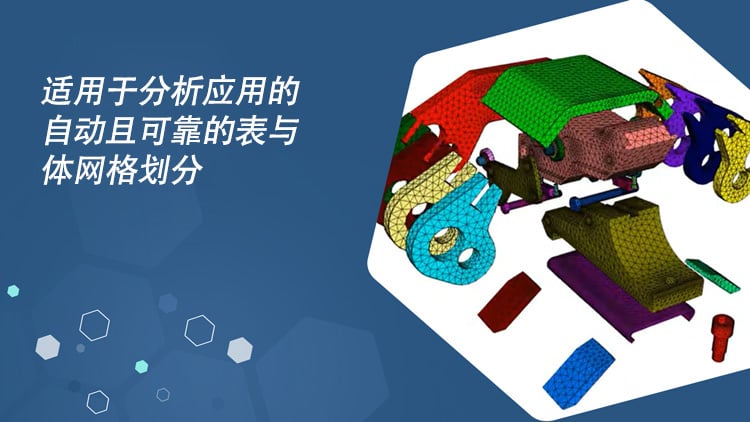

自动数据准备

Data Prep for 3D InterOp 利用强大的算法和最佳实施实践自动增强和丰富 3D 数据。利用数据预处理强大的过滤和压缩技术,您可以降低模型的复杂度和大小,屏蔽 IP 并定制输出。例如,您可以通过删除细节特征、小体、孔、圆角和隐藏体来简化仿真工作流程。

为 XR 优化 CAD 模型

CGM Modeler 通过使用先进的特征识别和挫败功能,可以简化 XR 工作流程并提高性能。此外,它还可以完全控制几何体的细分,让用户生成适合自己的可视化效果。使用 CGM 建模器,您可以使用同类最佳的 B-Rep 运算符对 3D 几何体进行精确建模,并使用布尔运算、变形、直接编辑等强大的运算符对其进行修改。CGM 还能使用快速、准确的运算符进行距离计算、包含、冲突检测等,从而实现高效的模型分析。

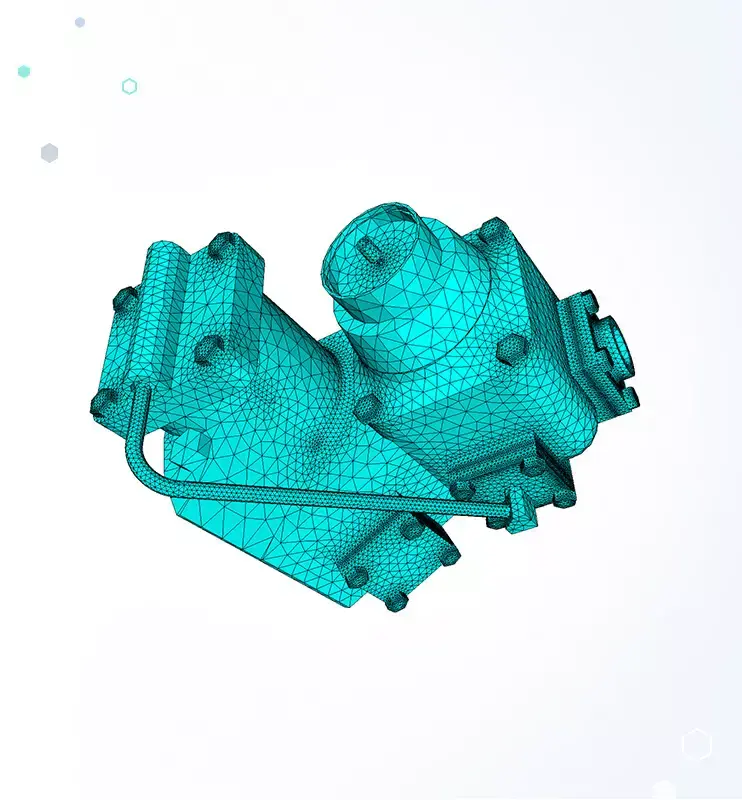

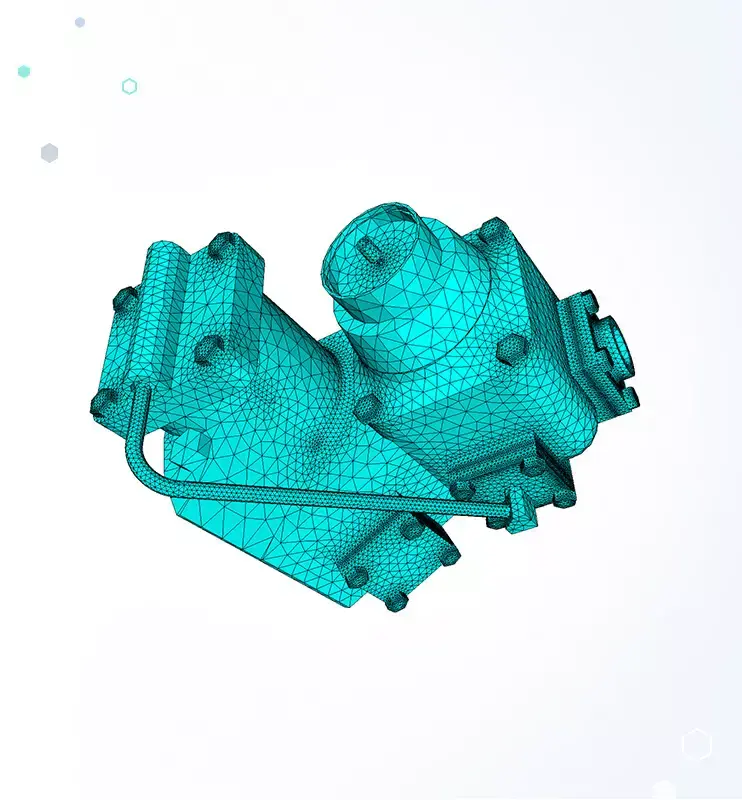

优化 XR 网格模型

当您的模型还未准备好进行可视化和细分时,CGM 多面体可提供修复网格的工具,以减少多边形数量。3D InterOp、CGM Modeler 和 CGM Polyhedra 的Spatial解决方案提供了不同的适应能力和选项,开发人员可以将其结合起来,在工作流程中准备数据,以获得最佳的体验效果。

功能

XR 工作流程

行业的独特需求。无论您的 XR 应用是用于虚拟培训和模拟、教育、虚拟原型设计和设计,还是娱乐和游戏,Spatial SDKs 的功能都能帮助您实现、

还是娱乐和游戏,Spatial SDK 的功能都能帮助您实现开发目标。

您的开发目标。

多功能 CAD 和 AEC 格式导入功能

多样化 XR 体验的基础

3D InterOp 可导入一系列 CAD 和 AEC 格式,使 XR 应用程序能够根据来自不同行业的双胞胎或设计创建体验。这种多功能性对于旨在构建身临其境的精确 XR 环境的开发人员来说至关重要。

.jpg?width=401&height=269&name=Rectangle%20335%20(1).jpg)

优化数据准备工作流程

为最佳 XR 体验定制数据

开发人员可以在工作流程中精心准备数据,确保 XR 体验获得最佳效果。这些工具的结合可实现精确的数据加载、视觉保真度维护、模型简化以及适合目标设备的场景生成。

为什么使用Spatial SDK 进行开发?

综合解决方案

缩短上市时间

定制和灵活性

持续创新

Spatial 致力于持续研究和开发,确保我们的 SDK 始终处于技术和行业趋势的前沿。

共同成长

浏览我们的资源

CAM工作流程的未来

探索当前和未来的计算机辅助制造 (CAM) 工作流程,以及提升 CAM 的方法。

机床制造企业的终极指南

为机床供应商提供的三部分指南,内容涵盖如何通过软件差异化提升硬件销售,以及如何选择合适的开发工具包。

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

FVA加速支持新及更新CAD格式

FVA的解决方案服务于传动系统行业,其软件能够进行复杂仿真和变速箱组件的详细分析。

CAM工作流程的未来

探索当前和未来的计算机辅助制造 (CAM) 工作流程,以及提升 CAM 的方法。

机床制造企业的终极指南

为机床供应商提供的三部分指南,内容涵盖如何通过软件差异化提升硬件销售,以及如何选择合适的开发工具包。

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

FVA加速支持新及更新CAD格式

FVA的解决方案服务于传动系统行业,其软件能够进行复杂仿真和变速箱组件的详细分析。

LK Metrology确保应用未来无忧

LK Metrology致力于保持其坐标测量机的精度。通过与Spatial的开发合作,他们提升了核心应用功能。

Renishaw大幅减少STL文件修复需求

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

Stäubli借助Spatial SDK提升产品与能力

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

FCC提升20倍生产时间

领先的钣金制造CAM软件提供商使用3D ACIS Modeler进行稳健的3D建模与仿真。

Renishaw大幅减少STL文件修复需求

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

Stäubli借助Spatial SDK提升产品与能力

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

FCC提升20倍生产时间

领先的钣金制造CAM软件提供商使用3D ACIS Modeler进行稳健的3D建模与仿真。

8 Reasons Why Developers Switch to HOOPS Visualize

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

CGM Modeler: A Platform for Innovation

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

CAM工作流程的未来

探索当前和未来的计算机辅助制造 (CAM) 工作流程,以及提升 CAM 的方法。

Healing as an Essential Function: Preserving Design Intent in 3D Models

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

数据的第二生命

了解模型修复和验证、其对建模操作的影响以及详细的测试结果。

CGM Modeler: A Platform for Innovation

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

CAM工作流程的未来

探索当前和未来的计算机辅助制造 (CAM) 工作流程,以及提升 CAM 的方法。

Healing as an Essential Function: Preserving Design Intent in 3D Models

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

数据的第二生命

了解模型修复和验证、其对建模操作的影响以及详细的测试结果。

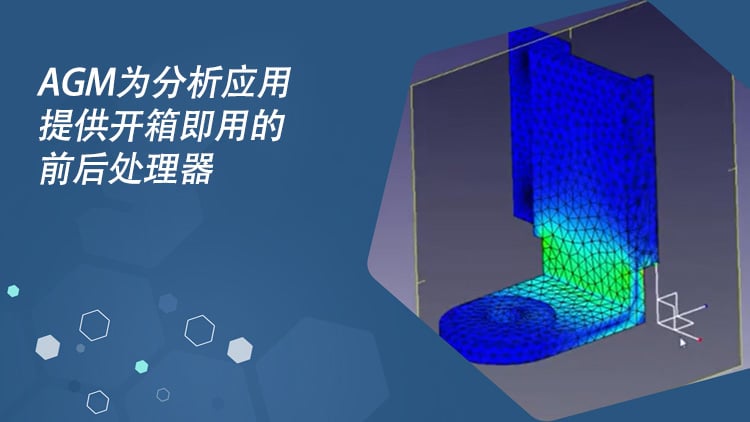

Accelerate your 3D Application’s Development with AGM

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

ALM: Maximizing the Lifespan and Value of an Application

Discover how Application Lifecycle Management impacts your revenue, shortens time to market, and extends your application's lifespan.

Bring Your Assembly Modeling to Life with Parametric Constraint Management

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Make Data Preparation for Simulation Easy

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Expand the Scope of Your Application to Enable Hybrid Manufacturing

Discover how to handle both CAD and scanned data for hybrid manufacturing.

ALM: Maximizing the Lifespan and Value of an Application

Discover how Application Lifecycle Management impacts your revenue, shortens time to market, and extends your application's lifespan.

Bring Your Assembly Modeling to Life with Parametric Constraint Management

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Make Data Preparation for Simulation Easy

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Expand the Scope of Your Application to Enable Hybrid Manufacturing

Discover how to handle both CAD and scanned data for hybrid manufacturing.

-for-robotics-applications-using-Spatial-SDKs-in-AGM.jpg?width=1440&name=Collision-detection-(near-miss)-for-robotics-applications-using-Spatial-SDKs-in-AGM.jpg)