Advanced Capabilities for CAM Engineering

Software is a key differentiator in machine building and tool manufacturing, driving the acceleration of process-oriented workflows. With Spatial’s 3D Software Development Kits (SDKs) and industry expertise, you can ensure seamless collaboration from CAD design to the manufacturing shop floor while elevating your efficiency and innovation.

Key Challenges Faced by CAM

Software Development Companies

CAD-to-CAM Collaboration

Facilitating smooth collaboration between CAD and CAM software to streamline workflows from design to manufacturing.Managing Software Complexity

Addressing the complexity of CAM programming to ensure usability even for simple parts, especially in small-lot, high-mix production environments.Automating Design Updates

Automating the reconfiguration of machining setups to accommodate CAD design updates efficiently.Feature Recognition and Optimization

Implementing feature recognition and defeaturing to analyze and optimize CAD models for advanced manufacturing processes.

How Spatial Solutions

Address Your Challenges

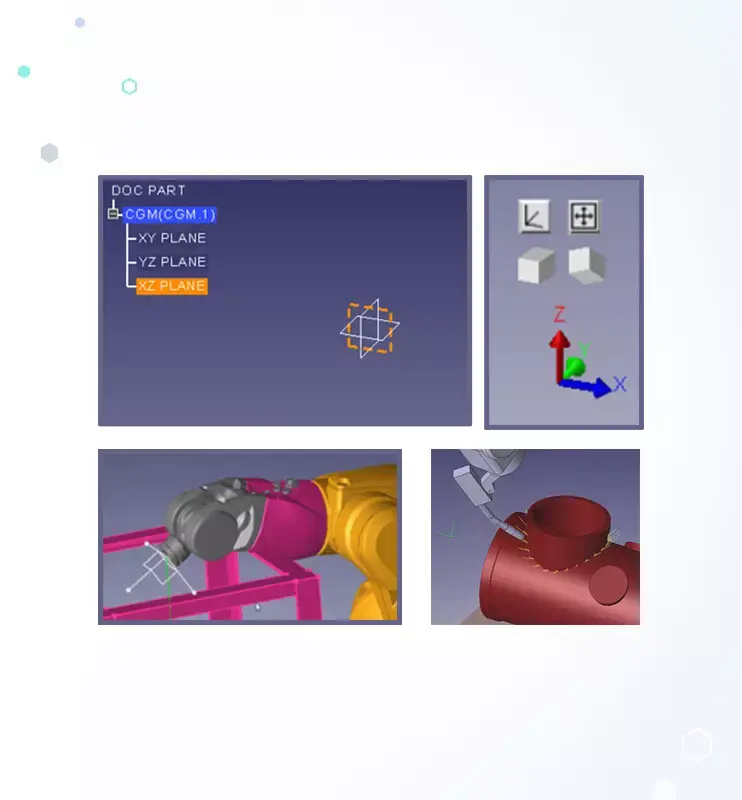

Empowering Automation

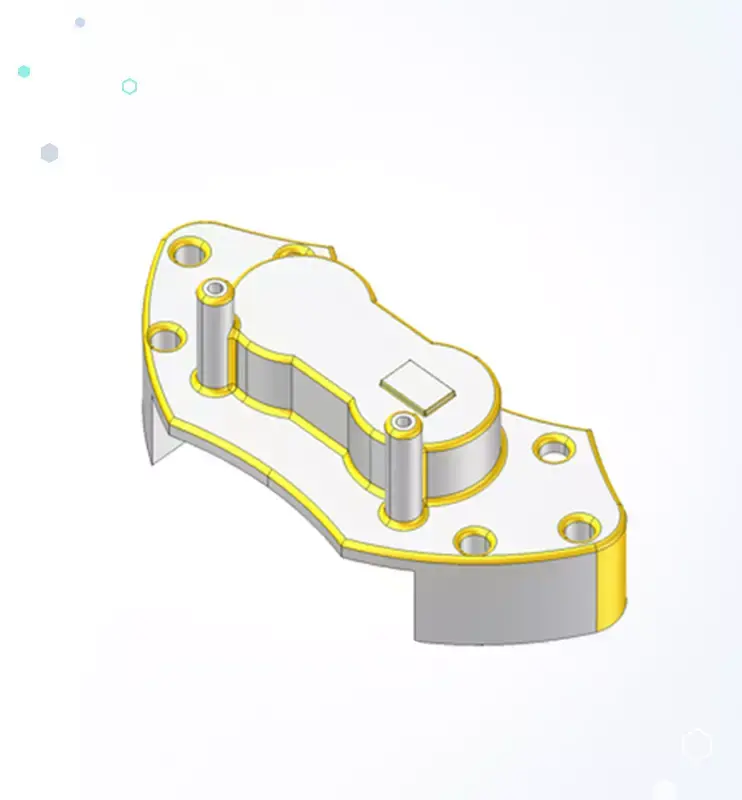

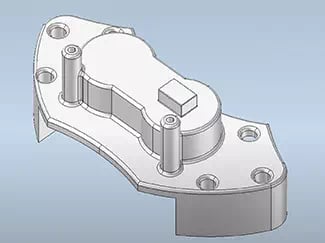

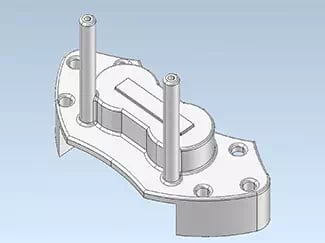

CGM facilitates industry-proven feature recognition and defeaturing that allows CAM engineers to automate the analysis and optimization of the CAD model for specific manufacturing and tooling processes. CGM Modeler’s feature recognition supports the range of manufacturing features on any imported model, such as holes, pads, pockets, fillets, chamfers and many more. Spatial’s Data Prep extends 3D InterOp to automatically optimize 3D data with robust algorithms, reducing model complexity and size using powerful filtering and compression techniques.

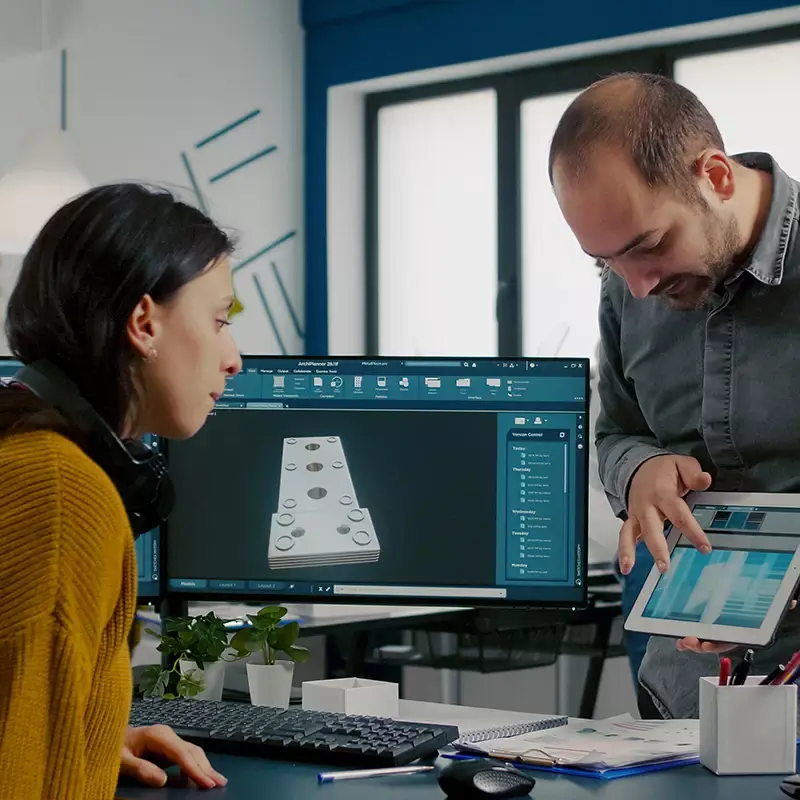

Seamless Collaboration

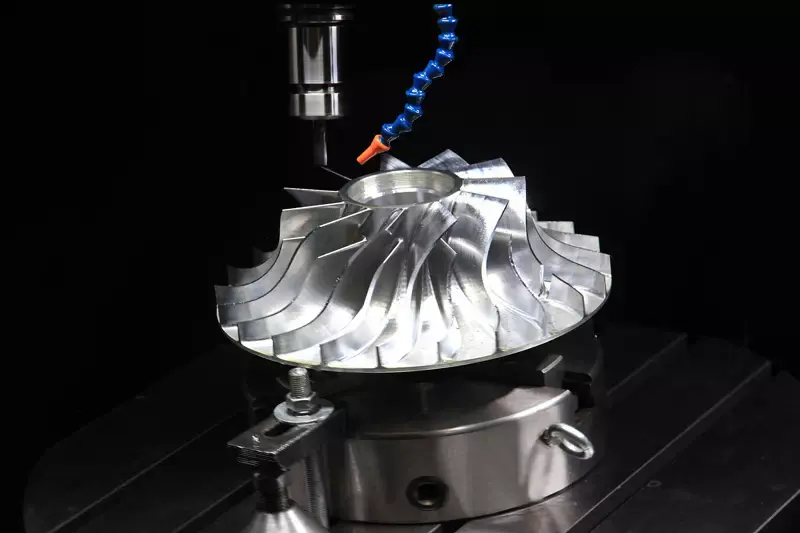

In the dynamic landscape of manufacturing, the integration and communication between the top floor (management, design, programming) and the shop floor (actual production area) are vital. Spatial solutions play a crucial role in bridging this gap. Spatial’s CGM Modeler and 3D InterOp aid CAM engineers in importing CAD models from different systems into your application, analyzing and optimizing these models with quick and direct geometry edits, as well as generating tool path calculations.

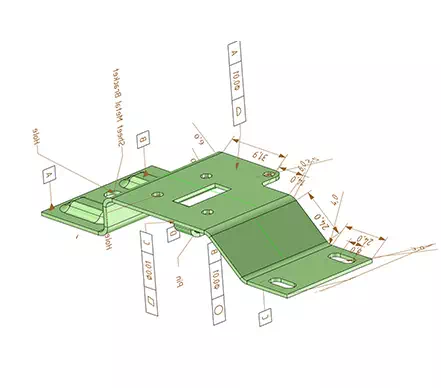

High Quality CAD and PMI Import

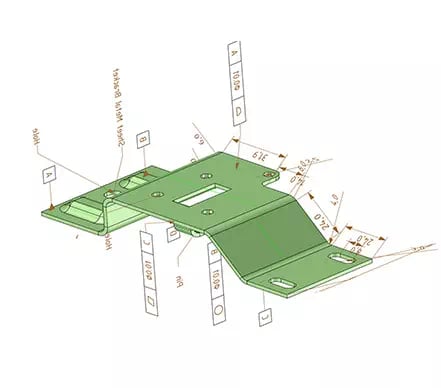

3D InterOp enables high-quality CAD import, and expertly handles B-rep geometry and non-exact geometry. It enables your application to work with an extensive breadth of CAD formats in a seamless, unified way. Additionally, with 3D InterOp, your team can build CAM software that automatically generates tool paths and preserves design intent by importing PMI (Product Manufacturing Information) from 3D CAD models. Our customers can achieve up to 90% time savings when utilizing PMI to create tool paths.

Specialized Graphics Framework

Application Graphics Manager (AGM) is a comprehensive 3D application development framework that offers a multifaceted toolset for developing robust 3D applications. It offers multiple layers of functionality, including a user interface framework, Object Lifecycle Management, specific features for undo/redo in geometry, a rendering engine and everything in between — all while integrating seamlessly with all other Spatial SDKs. AGM also offers fast collision checks, providing accurate and reliable simulations of machining processes to the CAM engineer.

Automate Your CAM Workflows

1. File open

- Part and Assembly Import

- Selective BREP Import

- Semantic & Graphical PMI

- CAD Associativity

2. Leverage Geometry, PMI, and Metadata

- Feature Recognition and Automatic Defeaturing

- Query PMI

- Query Metadata

Features Built for CAM Workflows

Spatial’s solutions have built-in functionality that targets the

unique needs of the CAM industry. Select capabilities include importing any BREP CAD,

healing and cleaning, part orientation operator and feature recognition.

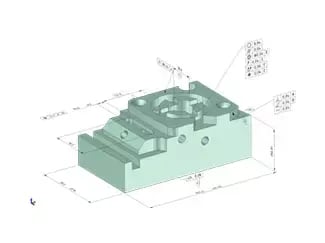

CAD Import

3D InterOp leverages the CGM kernel and native APIs to read/write a lot of file formats. Native APIs give your application a strong edge in terms of quality without requiring a CAD license. Incrementally import CAD data as individual containers, including product structure, tessellated geometry, exact geometry and manufacturing information, as needed by your application workflows.

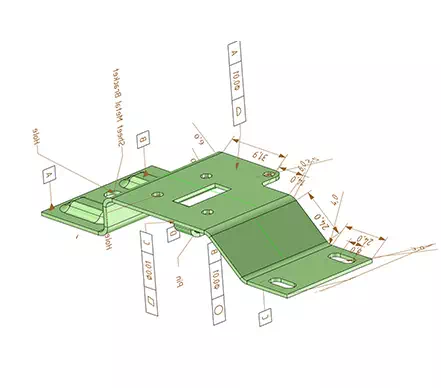

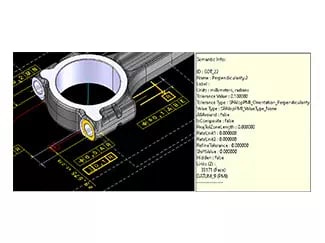

Semantic PMI Import

3D InterOp supports product manufacturing information in graphical and semantic form with full geometrical associativity, enabling engineering reviews and process automation for manufacturing and measurement.

CAD Associativity

Spatial's CAD Associativity capability allows for the automatic reconfiguration of machining setups in response to design updates.

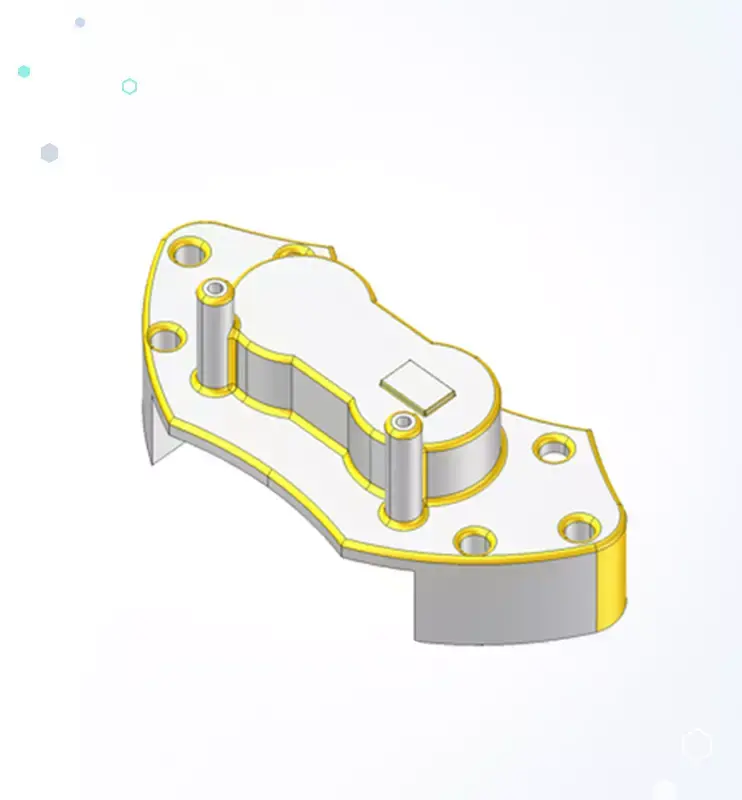

Feature Recognition and Defeaturing

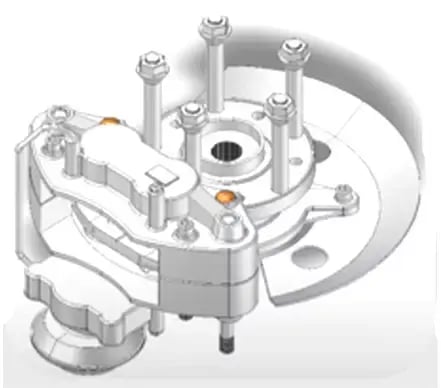

CGM Modeler embeds advanced feature recognition on any imported model without accessing the feature tree. Applications can leverage operators to identify features such as holes, pads, fillets and more, along with their defining parameters for manufacturing automation and model simplification for analysis.

Direct Editing

CGM Modeler and ACIS Modeler provide the best-in-class geometric operators for solid and surface modeling and direct editing. Applications can leverage operators to create the most complex 3D parts and assemblies commonly used in automotive, aerospace and other industries.

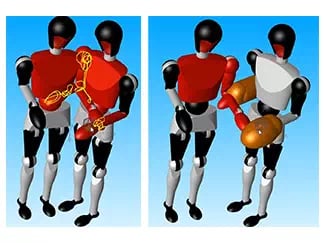

Collision Detection

AGM provides a common foundation of functionality among robotics applications. For example, representing robots, connecting robot controllers, importing work models and jigs, generating welding points, detecting collisions, robot manipulators, playing animations and more are all integral to successful robotics applications. This enables you to develop your next-generation robotics application rapidly.

Why Develop With Spatial SDKs?

Focus on Your Innovative Value-Add

Maximize Your Growth Potential

Minimize Risk and Reduce Cost

Focus on New Capabilities

Grow Together

Get Started With Spatial

Do we have the technology to take your 3D application workflows to the next level? Find out by speaking with a Spatial expert.

All Our Computer Aided

Manufacturing Resources

The Future of CAM Workflows

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

A 3 Part Guide for Machine Tool Manufacturers

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

Automated CAM Programming – Spatial & ModuleWorks

CAM software developers and machine builders can automate processes, reduce downtimes, and differentiate in the market with Spatial and ModuleWorks' expertise in automatic CAM solutions for prismatic parts.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

A 3 Part Guide for Machine Tool Manufacturers

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

Automated CAM Programming – Spatial & ModuleWorks

CAM software developers and machine builders can automate processes, reduce downtimes, and differentiate in the market with Spatial and ModuleWorks' expertise in automatic CAM solutions for prismatic parts.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

A 3 Part Guide for Machine Tool Manufacturers

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

The Future of CAM Workflows

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

How to Successfully Develop, Deploy, and Support 3D Applications

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

Additive Manufacturing - Top 5 Ways to Increase Revenue and Margins

Explore scenarios for Additive Manufacturing OEMs to offer complete solutions, impacting revenue and margins.

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

The Future of CAM Workflows

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

How to Successfully Develop, Deploy, and Support 3D Applications

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

Additive Manufacturing - Top 5 Ways to Increase Revenue and Margins

Explore scenarios for Additive Manufacturing OEMs to offer complete solutions, impacting revenue and margins.