包括的な機能性

幾何オブジェクト間に寸法拘束や論理拘束を付与し、2Dプロファイルや3Dアセンブリの位置合わせを行うための包括的な機能を提供します。

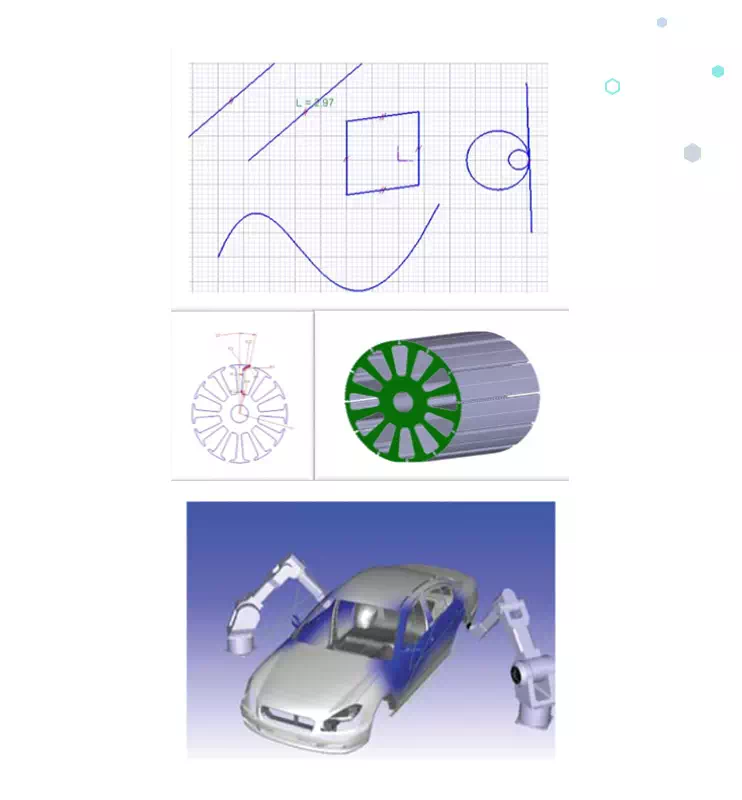

Constraint Design Solver (CDS)は、部品やアセンブリ設計の可能性を最大限に引き出します。この先進的なSDKは、2Dおよび3Dモデルのスケッチとコンポーネントの位置を再計算し、すべての設計要素が指定された拘束条件を満たすことを確認します。実世界での正確なシミュレーション動作を必要とするアプリケーションに最適なCDSは、幅広い拘束条件をサポートし、最も複雑な幾何学的関係も扱える高性能ソルバーを提供します。CDSで生産性を高め、市場投入までの時間を短縮し、設計精度を向上させましょう。

幾何オブジェクト間に寸法拘束や論理拘束を付与し、2Dプロファイルや3Dアセンブリの位置合わせを行うための包括的な機能を提供します。

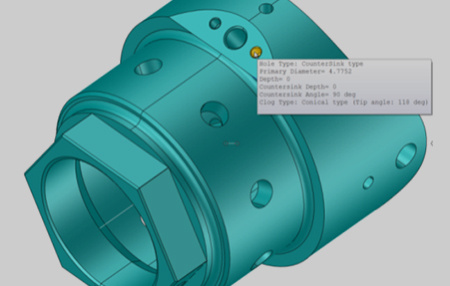

ロバストで迅速かつ柔軟なスレッドセーフなソルバーが、複数のソルバーオプションと診断ツールにより、拘束不足や過剰拘束の問題を解決、または解析します。

デバッグ機能とリアルタイムフィードバックを備えた包括的なインターフェイスにより、CDSをアプリケーションに迅速に実装できます。オブジェクト指向設計により、自己完結型のC++ APIを実装するための明確なインターフェイスを提供します。

スペイシャルは、迅速な導入のための「スタートアップ」アプリケーション インフラストラクチャの中でも、必要不可欠な機能を提供します。

CDSによって、開発者は幾何学的な拘束条件を解くことの数学的複雑さを考慮する必要がなくなり、コアコンピテンシーに自由に集中できるようになり、生産性を向上させ、市場投入までの時間を短縮します。

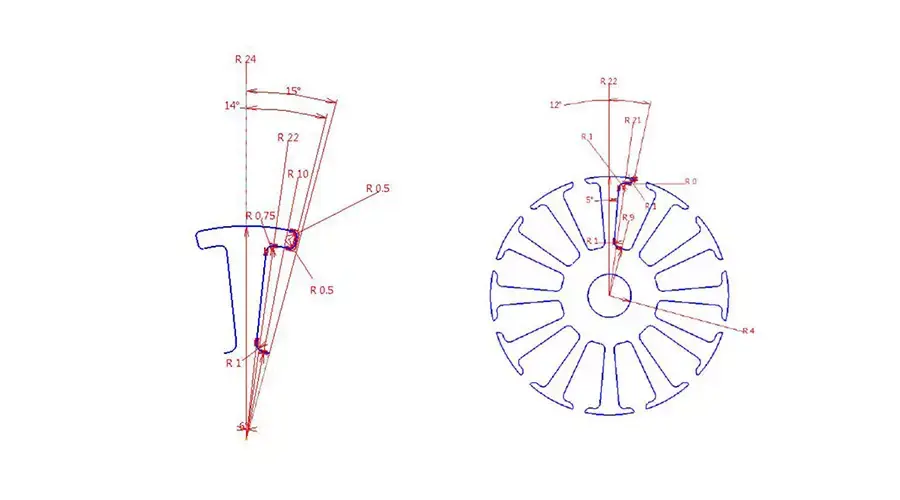

座標、距離、長さ、半径、角度、曲率など、さまざまな寸法拘束を使い、特定の値を指定することができます。また、一致、接線、平行、垂直、対称などの論理的な拘束を使って、幾何学的なオブジェクト間の位置関係を拘束することもできます。

次世代3Dアプリケーションのための究極のモデリング技術。CGM Modelerで3Dデータの作成、修正、クエリ、可視化を実現。

長年にわたって業界をリードしてきた3D形状処理モデリングカーネル。ACIS Modelerは、数百万のユーザーに向けて改良を積み重ね、数十年にわたり産業の発展を支えてきたプラットフォーム。

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Discover Automatic CAM, the enabling processes, and its application benefits.

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Discover Automatic CAM, the enabling processes, and its application benefits.

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

Understand model repair and validation, its impact on modeling operations, and detailed test results.

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

Understand model repair and validation, its impact on modeling operations, and detailed test results.

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

Discover how Application Lifecycle Management impacts your revenue, shortens time to market, and extends your application's lifespan.

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Discover how Application Lifecycle Management impacts your revenue, shortens time to market, and extends your application's lifespan.

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

.jpg?width=1440&name=Sketcher-Feature-in-the-Application-Graphics-Manager-(AGM).jpg)

-for-robotics-applications-using-Spatial-SDKs-in-AGM.jpg?width=1440&name=Collision-detection-(near-miss)-for-robotics-applications-using-Spatial-SDKs-in-AGM.jpg)