软件开发的主要挑战

增材制造软件开发的挑战

可打印性

解决几何形状不正确、壁薄、面缺失和方向等常见问题,确保模型为 3D 打印做好准备。互操作性

促进设计软件与快速成型制造软件之间的无缝集成,使工作流程更加顺畅。数据完整性

在三维模型从设计到制造的整个生命周期内,保持其质量和准确性。上市时间

通过简化开发流程,更快地交付解决方案,满足客户需求。

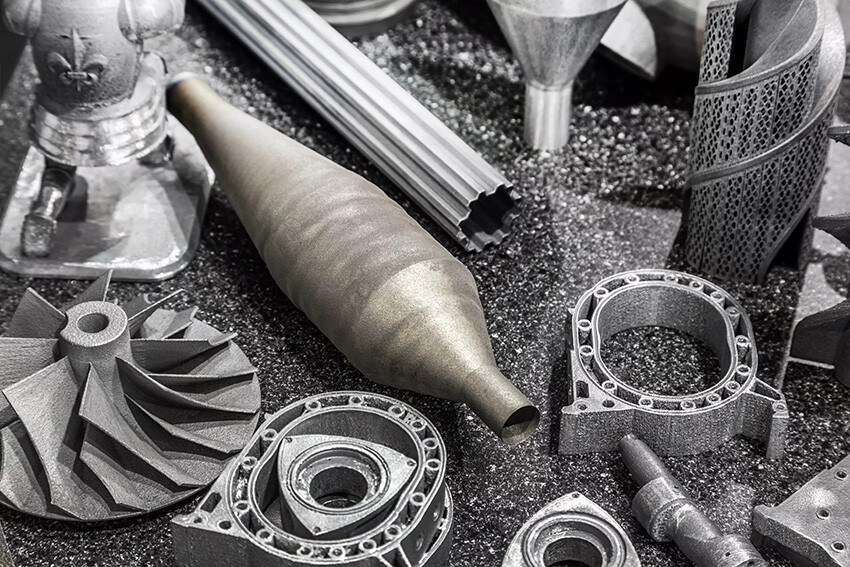

了解我们针对快速成型制造的全套解决方案

利用 3D InterOp 无缝导入 CAD

Spatial 的快速成型制造工具包包括 3D InterOp,它可实现一流的 CAD 导入,并能专业地处理 B-rep 几何图形和非精确几何图形。它使您的应用程序能够以无缝、统一的方式处理多种 CAD 格式。

先进的 B-rep 和多面体建模功能

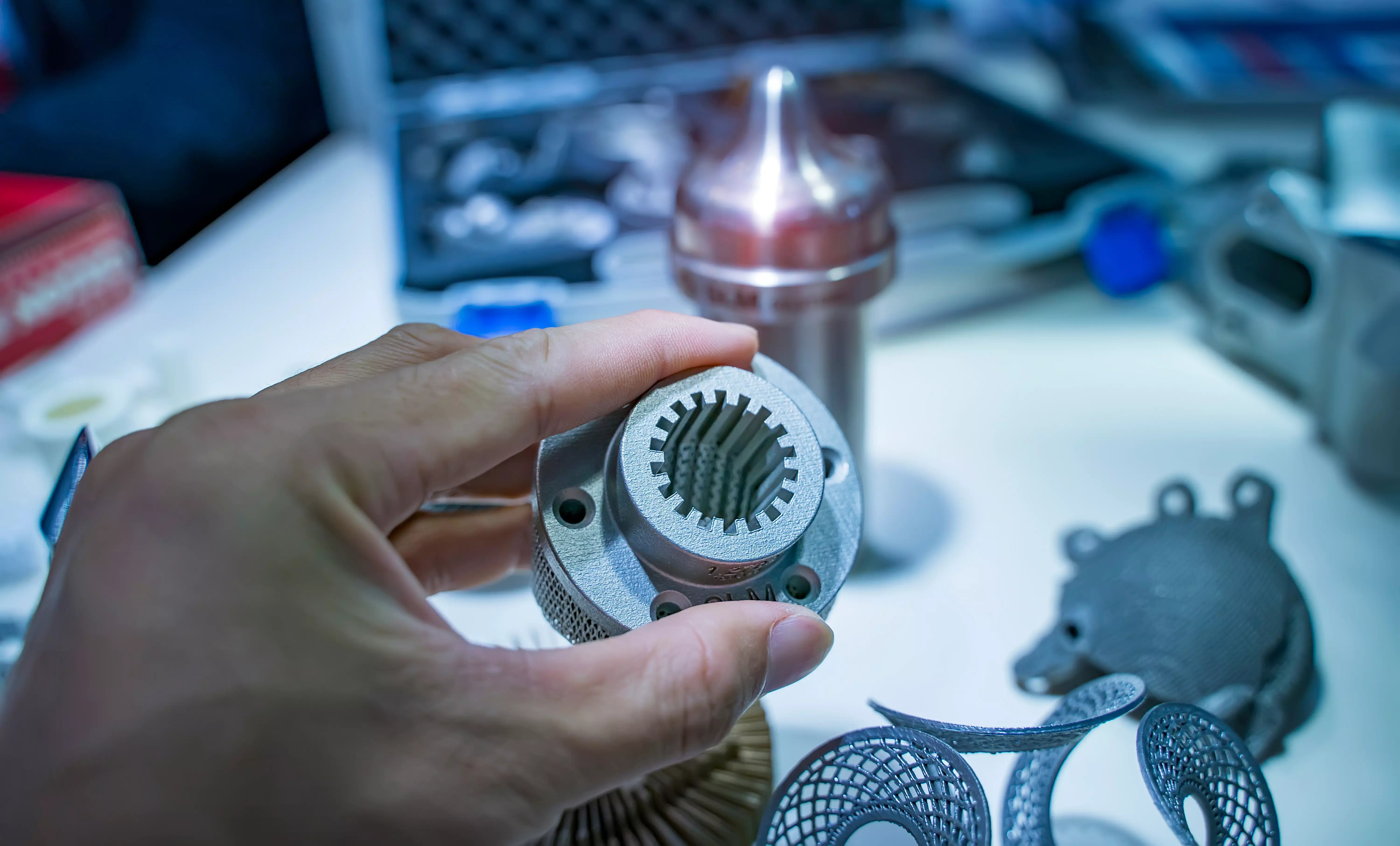

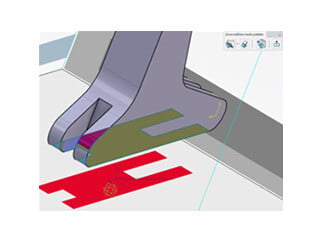

CGM 是我们功能强大的建模工具,其附加功能 CGM 多面体可提供几何特征识别、剔除、B-rep 直接编辑、愈合和清理等建模功能。小于打印机分辨率的特征通常需要在打印后通过机械加工添加到零件上。几何功能允许软件自动识别和移除低于打印机分辨率的特征,并利用小孔位置和尺寸信息驱动二次加工操作。

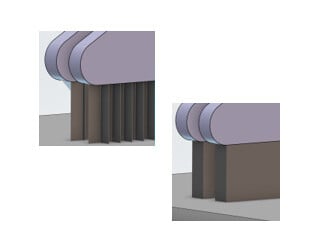

使用薄壁固体进行高效印刷

打印实体几何体通常会使用过量的材料,并在冷却过程中产生热变形。薄壁实体可以使用更少的材料打印出相同的外部形状,并产生更少的热量。Spatial 行业领先的三维建模器可提供三维模型的完整边界表示,使您能够在打印前以可控壁厚对实体进行加壳,并在承重区域指定额外厚度。

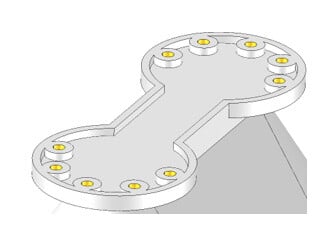

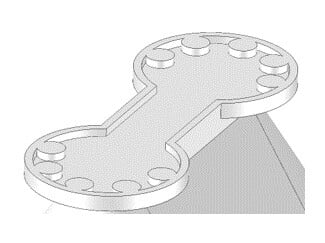

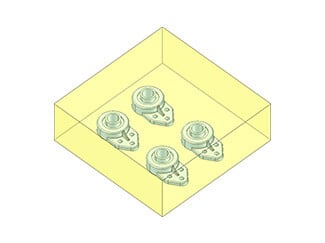

实现规模制造

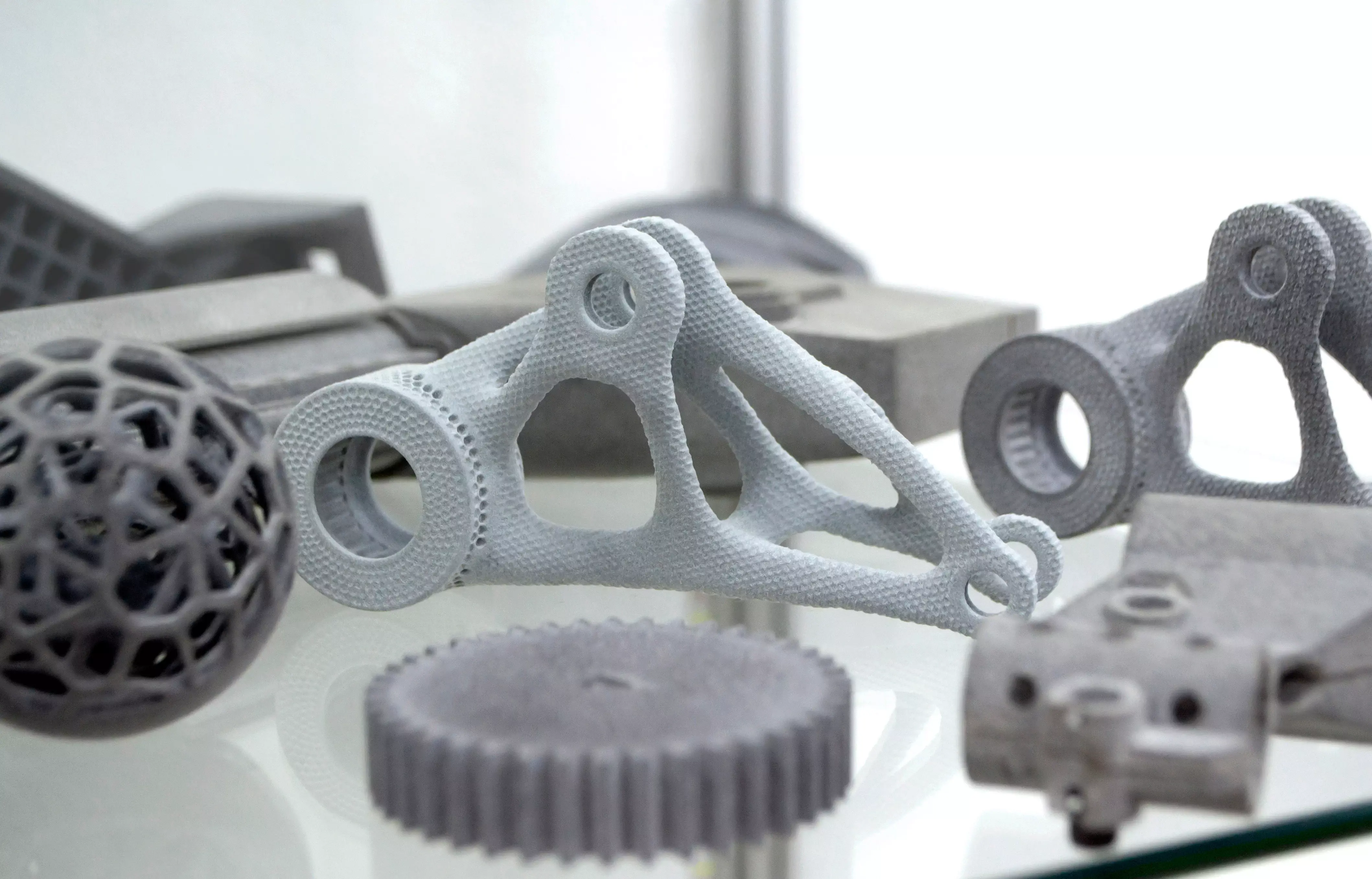

通过在预定义空间中嵌套多个零件实例,实现规模化制造。二维和三维排版允许在所有三个方向对零件进行定向和排版。通过自动调整零件方向来优化支持材料体积,从而最大限度地降低材料成本。这通常用于不需要生成支撑材料的 3D 打印应用。

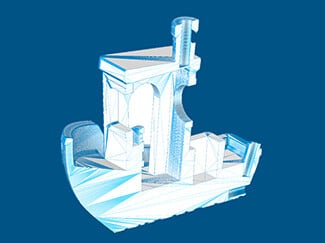

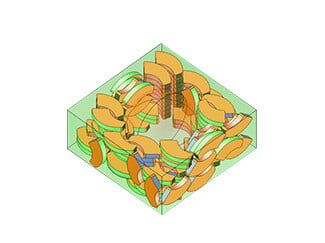

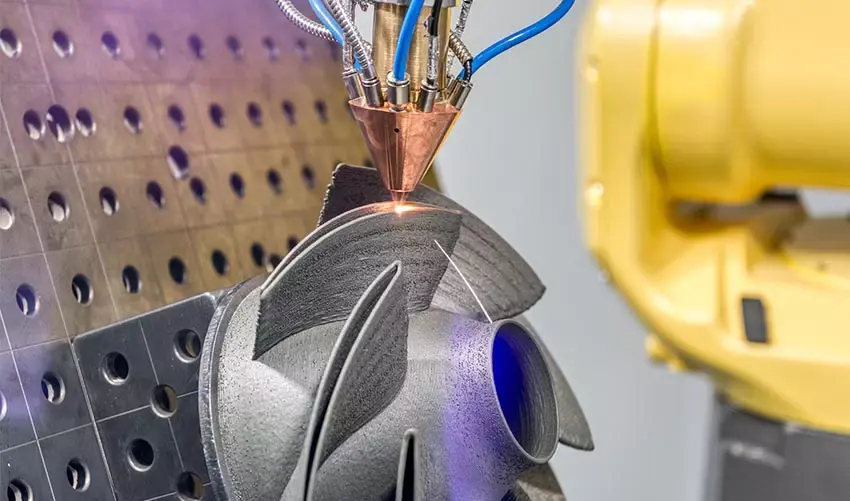

为金属印刷工艺提供支持

通过自动支撑区计算、线(非实体)支撑以及锥体和体积(实体)支撑,改善散热并自动生成支撑。这非常适合 PBF 等金属打印工艺。

专为快速成型制造而设计的功能

制造工作流程

软件公司的独特需求。无论您是三维打印机的 OEM 还是 AM 行业的 ISV,我们的

SDK 都将帮助您实现开发目标。

全面的数据导入和自动修复

3D InterOp 支持导入各种 CAD 数据格式。

支持的一些 CAD 格式包括 STL、3MF、OBJ、AMF、CATIA、SolidWorks、NX、STEP 和 IGES。在此查看完整列表(链接三维互操作页面)

ACIS 和 CGM 多面体提供自动修复功能,确保脏的 STL 数据可以轻松修复并准备用于打印。

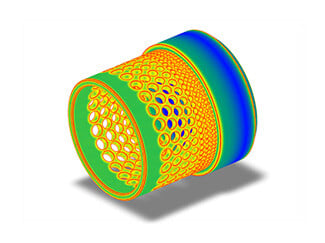

壁厚分析

壁厚分析工具可减少多次打印迭代的需要。在应用程序中建立一个预处理器,帮助事先验证最终打印的结构,确保打印部件的强度和稳定性。

识别并纠正导致热积聚的厚区域、结构不健全的薄区域以及工艺可能不支持的尖锐边缘和角落。

先进的自动 2D、2.5D 和 3D 排版实现高效制造

我们的自动 2D、2.5D 和 3D 嵌套功能可在预定义空间内精确放置多个零件实例,从而显著提高制造效率。

与传统的边界框方法相比,该功能可实现更紧密的配合,从而减少对支撑材料的需求并优化材料的使用。

零件会自动调整方向,以防止互锁并方便后期处理。此外,您还可以自定义嵌套区域并指定排除区域,从而使布局符合特定的生产需求。

自动生成支持

该技术可计算支撑区域,并提供多种支撑形状,确保每个印刷品都能得到充分的支撑,从而获得高质量的效果。该工艺非常适合 PBF 等金属打印工艺。

支撑区形状:线状(非实心)支撑、锥形和体积状(实心)支撑。

为什么要使用Spatial SDK?

软件中的整个三维模型生命周期。结合我们的专家指导,您将受益于独特的优势

的独特优势。

独享多种核心技术

与解决方案顾问合作

访问特定行业的应用程序接口

加速创新

我们所有的快速成型

制造资源

Renishaw大幅减少STL文件修复需求

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

Additive Manufacturing - Top 5 Ways to Increase Revenue and Margins

Explore scenarios for Additive Manufacturing OEMs to offer complete solutions, impacting revenue and margins.

机床制造企业的终极指南

为机床供应商提供的三部分指南,内容涵盖如何通过软件差异化提升硬件销售,以及如何选择合适的开发工具包。

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

Enable Automatic Supports Creation in your 3D Printing Application

Explore our new additive manufacturing capabilities within CGM Modeler in this webinar.

Additive Manufacturing - Top 5 Ways to Increase Revenue and Margins

Explore scenarios for Additive Manufacturing OEMs to offer complete solutions, impacting revenue and margins.

机床制造企业的终极指南

为机床供应商提供的三部分指南,内容涵盖如何通过软件差异化提升硬件销售,以及如何选择合适的开发工具包。

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

Enable Automatic Supports Creation in your 3D Printing Application

Explore our new additive manufacturing capabilities within CGM Modeler in this webinar.

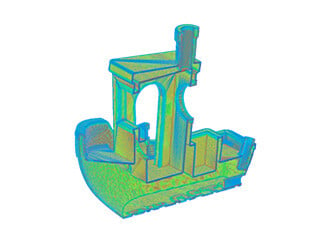

Expand the Scope of Your Application to Enable Hybrid Manufacturing

Discover how to handle both CAD and scanned data for hybrid manufacturing.

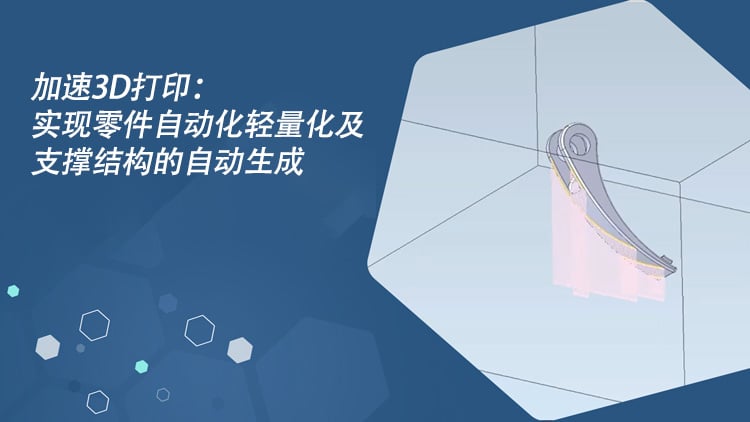

Technical Series: Enable Automated Lightweighting of Parts and Creation of Supports for Additive Manufacturing

Discover how your 3D application can leverage CGM Modeler’s Automated Lightweighting and Support Creation capabilities.

Bring Your Assembly Modeling to Life with Parametric Constraint Management

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

ACIS Polyhedra - Mesh Handling for ACIS Customers

Convert ACIS B-Rep bodies into meshes or import meshes directly into 3D ACIS Modeler for advanced model manipulation and preparation.

Accelerate your 3D Application’s Development with AGM

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

Technical Series: Enable Automated Lightweighting of Parts and Creation of Supports for Additive Manufacturing

Discover how your 3D application can leverage CGM Modeler’s Automated Lightweighting and Support Creation capabilities.

Bring Your Assembly Modeling to Life with Parametric Constraint Management

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

ACIS Polyhedra - Mesh Handling for ACIS Customers

Convert ACIS B-Rep bodies into meshes or import meshes directly into 3D ACIS Modeler for advanced model manipulation and preparation.

Accelerate your 3D Application’s Development with AGM

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

CGM Modeler: A Platform for Innovation

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

8 Reasons Why Developers Switch to HOOPS Visualize

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

5 Essential Functions of 3D ACIS Modeler

Explore the core functions of 3D ACIS Modeler: creating, modifying, querying, managing, verifying, and healing.

CAM工作流程的未来

探索当前和未来的计算机辅助制造 (CAM) 工作流程,以及提升 CAM 的方法。

Automatic CAM (ACAM) in Subtractive CNC Machining

Discover Automatic CAM, the enabling processes, and its application benefits.

8 Reasons Why Developers Switch to HOOPS Visualize

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

5 Essential Functions of 3D ACIS Modeler

Explore the core functions of 3D ACIS Modeler: creating, modifying, querying, managing, verifying, and healing.

CAM工作流程的未来

探索当前和未来的计算机辅助制造 (CAM) 工作流程,以及提升 CAM 的方法。

.jpg?width=1440&name=Sketcher-Feature-in-the-Application-Graphics-Manager-(AGM).jpg)