ABB Case Study

Market: Robotics, CAM

Summary

In addition Spatial’s InterOp CAD translators make it easy for ABB to provide solutions for customers that want to convert data from their existing CAD systems into an SAT format.

Spatial’s technology is a critical component of the increased engineering productivity ABB’s RobotStudio is realizing. This improvement is seen during the entire lifecycle of a robot system from the planning stages to design, implementation and retooling.

Working with Spatial has been pleasant and effortless and we've found it easy to work with their components. And we would wholeheartedly recommend Spatial for similar development efforts.

The Company

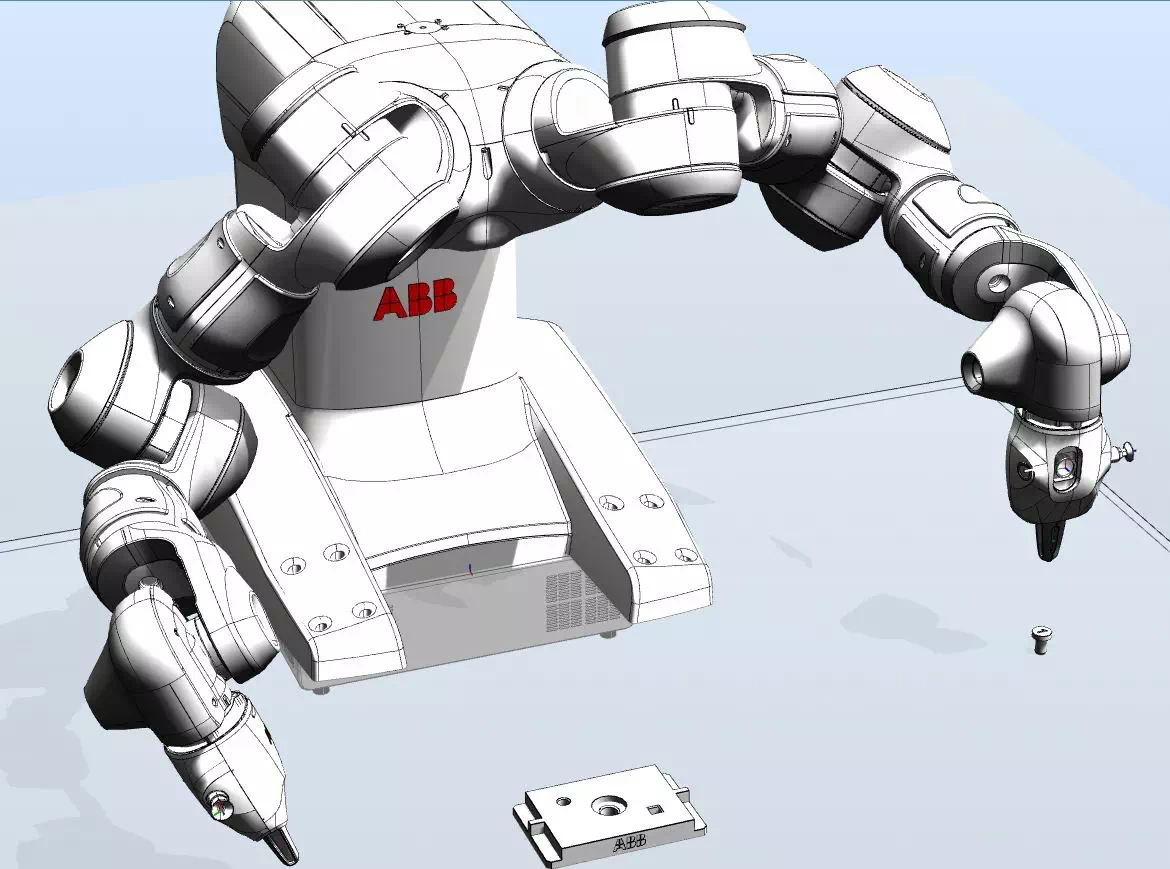

ABB is a technology-based provider of power and automation products, systems, solutions, and services. Its Robotics Division is a leading supplier of industrial robots, robot software, peripherals and services for manufacturing. Key markets include automotive, plastics, metal fabrication, foundry, electronics, machine tools, pharmaceutical and food and beverage industries. ABB has installed more than 250,000 robots worldwide.

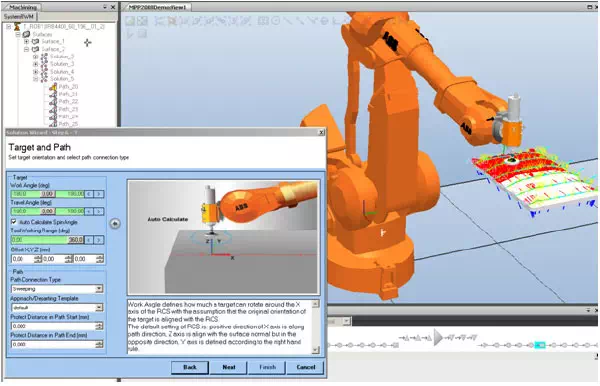

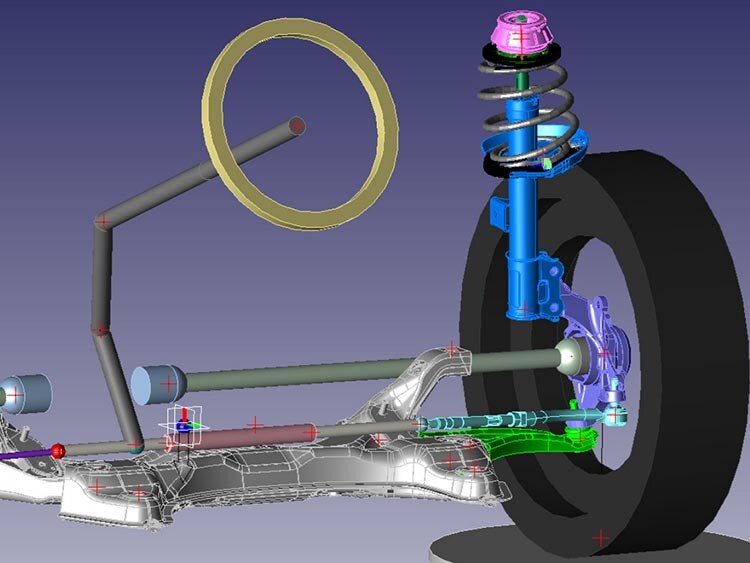

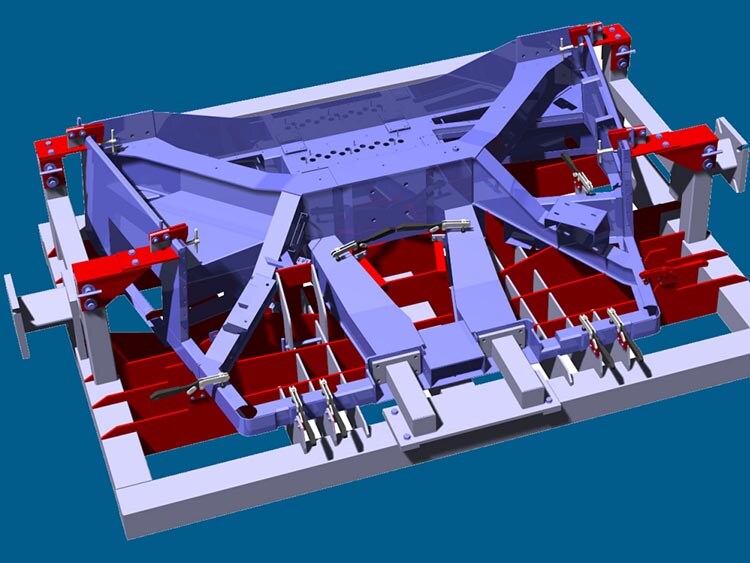

ABB’s RobotStudio software is the primary engineering tool for robot systems in a virtual environment. RobotStudio is a .net application using Microsoft Visual Studio Tools for Applications (VSTA) for the development environment; to develop products to run on VISTA. Approximately 20 developers work to release a new version every six months. RobotStudio is used in a wide range of functions: proposal engineers and sales people at systems integrators use it in the proposal stage to show potential customers proposed robot systems.

The Challenge

Embedding a New Geometry Engine

ABB needed a new geometry engine but to develop its own would have been an extensive undertaking well out of the realm of their core competency of robotics.

The Solution

Partnering with Experts in 3D Technology

ABB selected Spatial because it is the gold standard in the industry. The current release of RobotStudio is 5.11 and Spatial’s 3D ACIS geometry engine has been integrated since the beginning. Bertil Thorvaldsson, ABB Product Manager, Software Products, and team view RobotStudio’s 3D environment critical to the robotics software’s success.

ABB had considered Parasolid and any number of other solid modeling solutions. The company chose Spatial because SAT is an industry standard that can be certified; the SAT format can be generated by almost any CAD system. “In addition,” says Thorvaldsson, “Spatial’s CAD converters make it easy for us to provide solutions for customers that want to convert data from their existing CAD systems into the SAT format.”

The fact that Spatial is primarily in the business of providing components makes it a natural complement for ABB and the RobotStudio developers. “Solid modeling is very important to us, but designing the geometry engine ourselves would not have made sense,” notes Thorvaldsson.

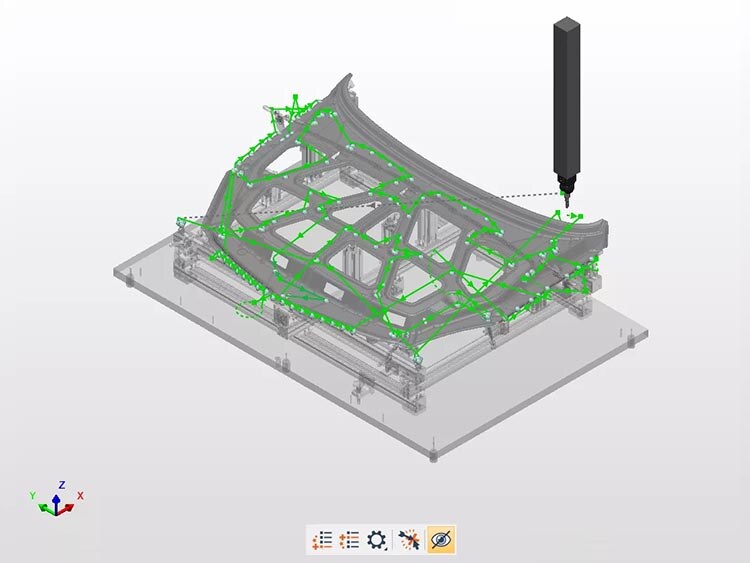

Spatial InterOp translators enable RobotStudio to easily import data in major CAD formats, including IGES, STEP, VRML, VDAFS, ACIS and CATIA. By working with this very exact data the robot programmer is able to generate more accurate robot programs, giving higher product quality.

This is one of the most timesaving features of RobotStudio. By using a CAD model of the part to be processed it is possible to automatically generate the robot positions needed to follow the curve in just a few minutes, a task that would otherwise take hours or days.

Spatial InterOp translators enable RobotStudio to easily import data in major CAD formats, including IGES, STEP, VRML, VDAFS, ACIS and CATIA. By working with this very exact data the robot programmer is able to generate more accurate robot programs, giving higher product quality.

For ABB’s system integrator customers, RobotStudio and integrated Spatial technology enables them to propose a better system and achieve a higher proposal win percentage. RobotStudio provides end user manufacturing customers many cost and time saving benefits during design and implementation through to retooling and implementation of new fixtures. The accuracy of the software eliminates or significantly reduces the need for rework because all programming and changes are done in a virtual environment.

The software also provides the flexibility to experiment with different alternatives to determine the best solution cost-effectively. “With a small effort on our part we can always provide the latest in 3d modeling,” says Thorvaldsson. “We integrate the latest version of ACIS and InterOp in everything we have; Spatial makes it effortless for us to put state of the art technology in our Product.”

The Results

Increased Engineering Productivity

RobotStudio increases engineering productivity during the entire lifecycle of a

robot system from the planning stages to design, implementation and retooling.

Spatial’s technology is a critical component.

Key Insights

Solutions

Implementing Spatial’s industry-proven technology relieves the burden to implement modeling functionality and manage geometry; realizing a large savings of effort to license components as compared to developing it in-house. System integrators and end user customers are able to increase productivity.Download the full case study

Discover how ABB Robotics tackled their engineering challenges with Spatial's SDKs. Download the complete case study to explore the approach, solution, and outcomes.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

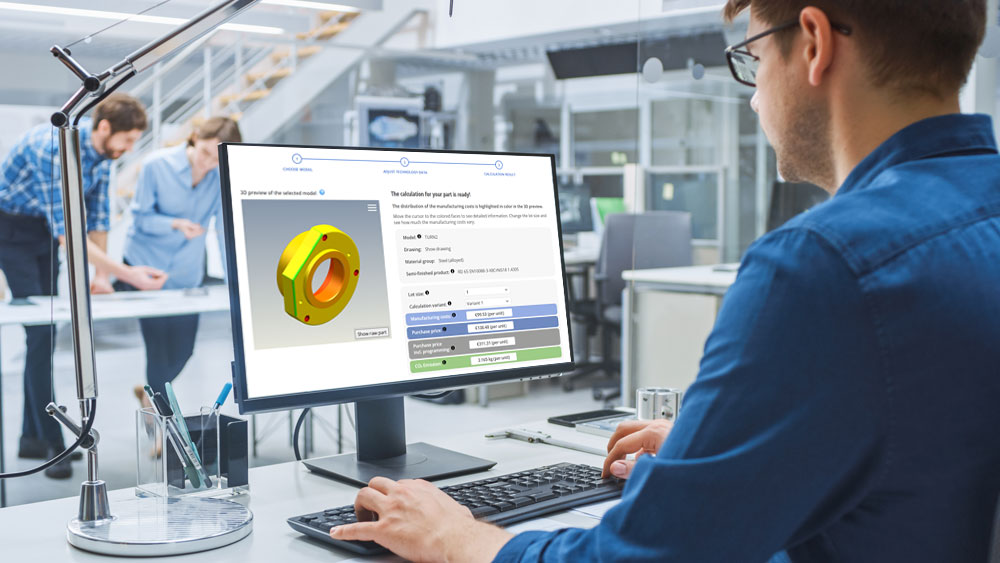

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.

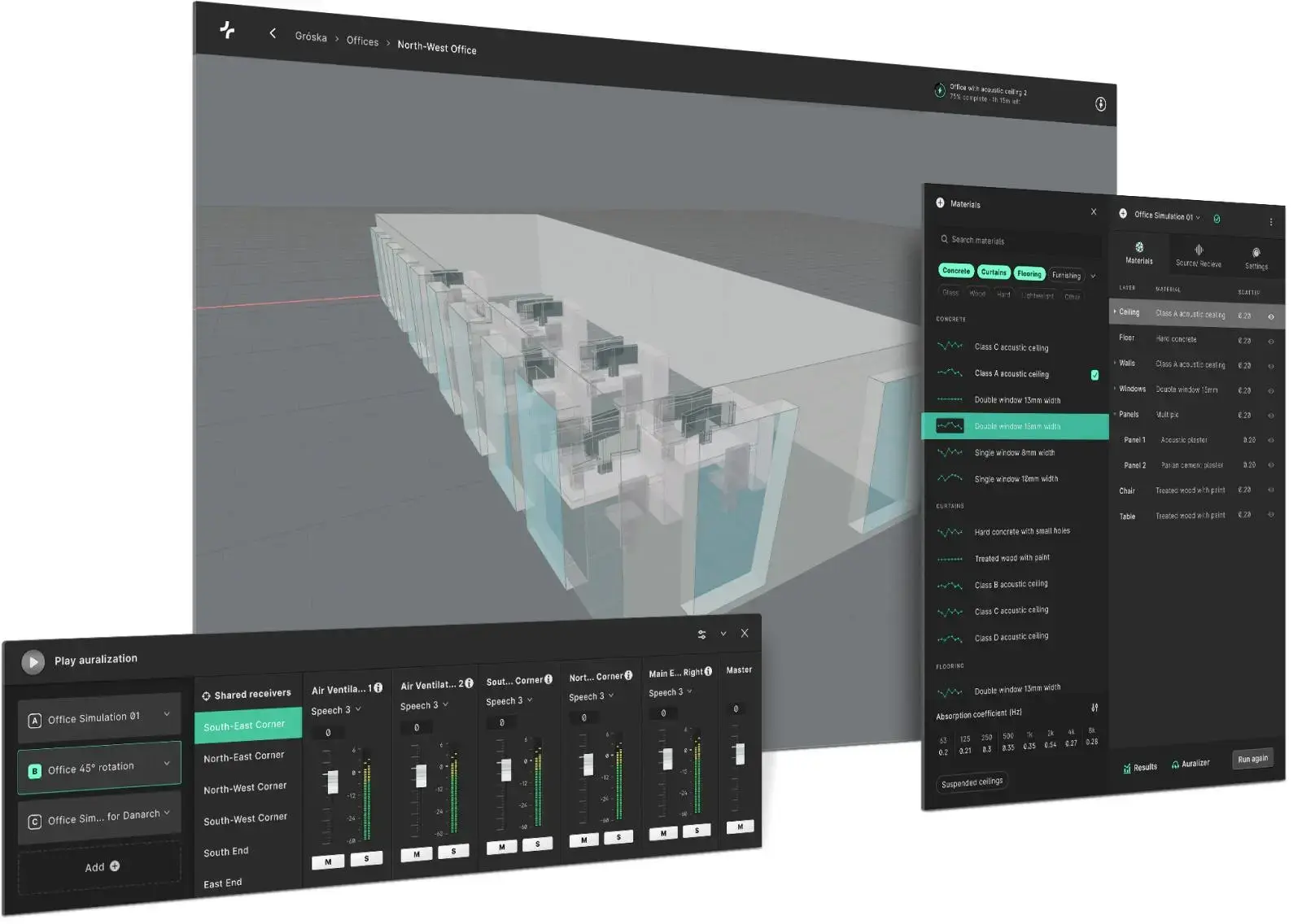

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

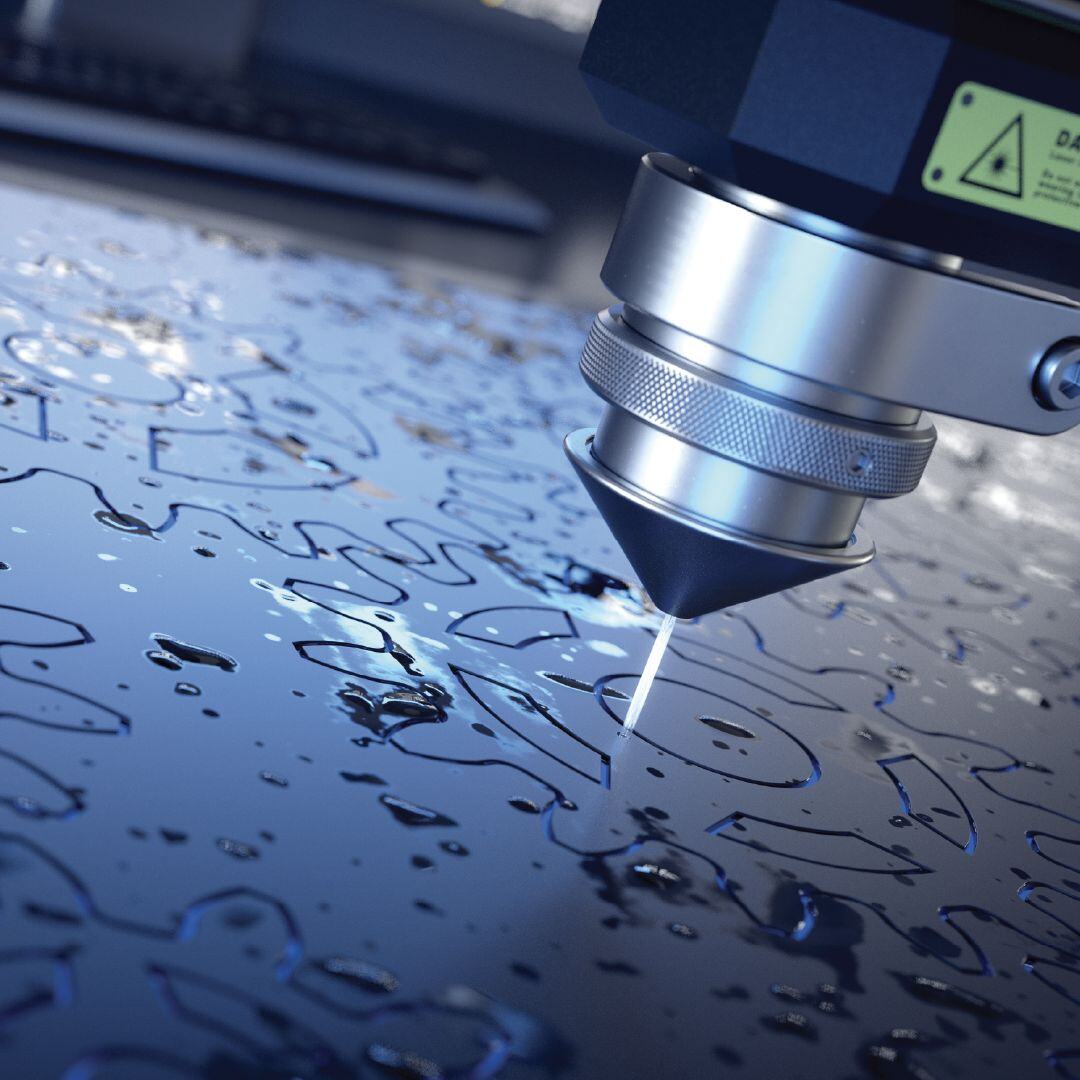

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

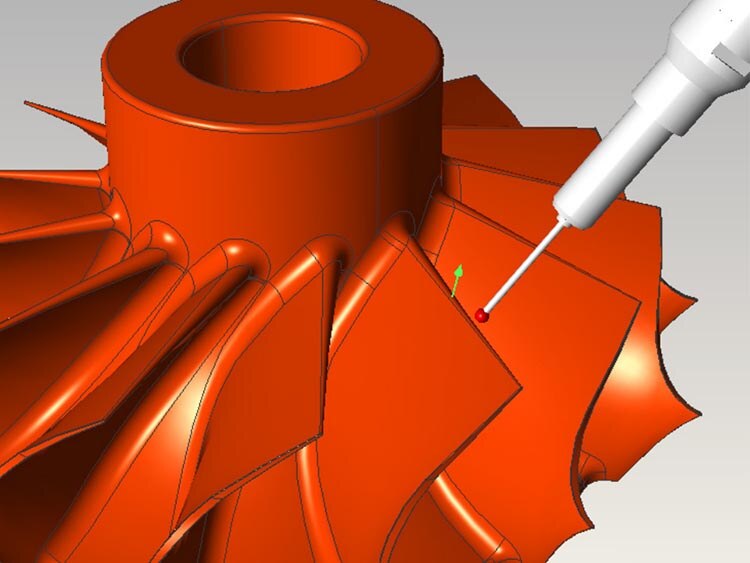

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

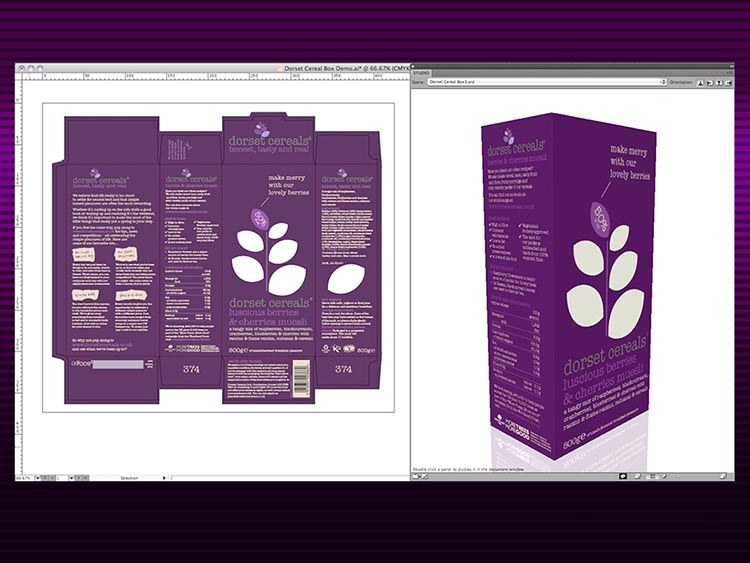

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

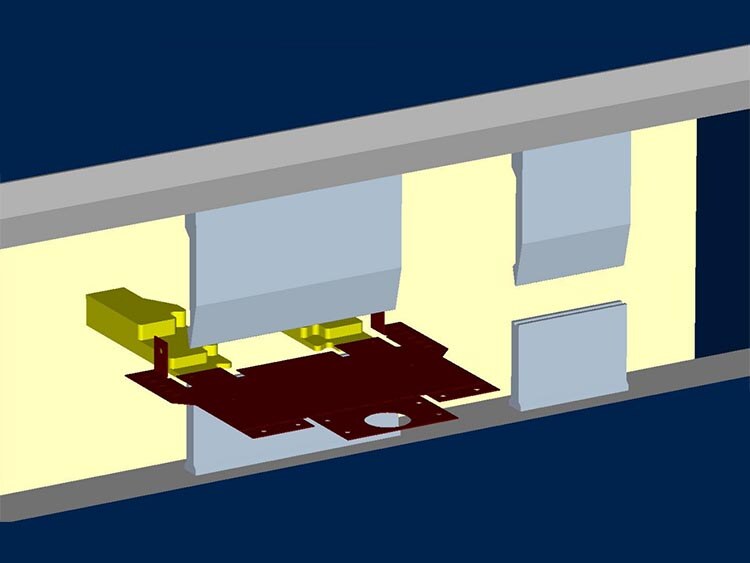

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

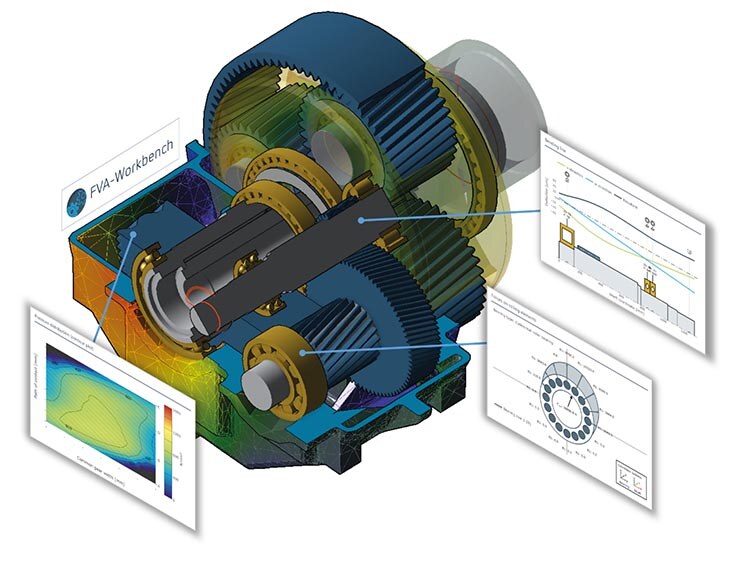

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

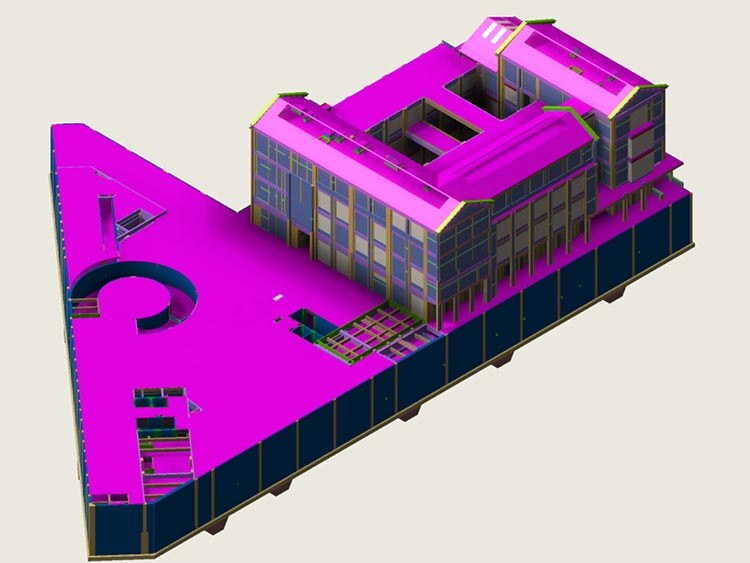

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

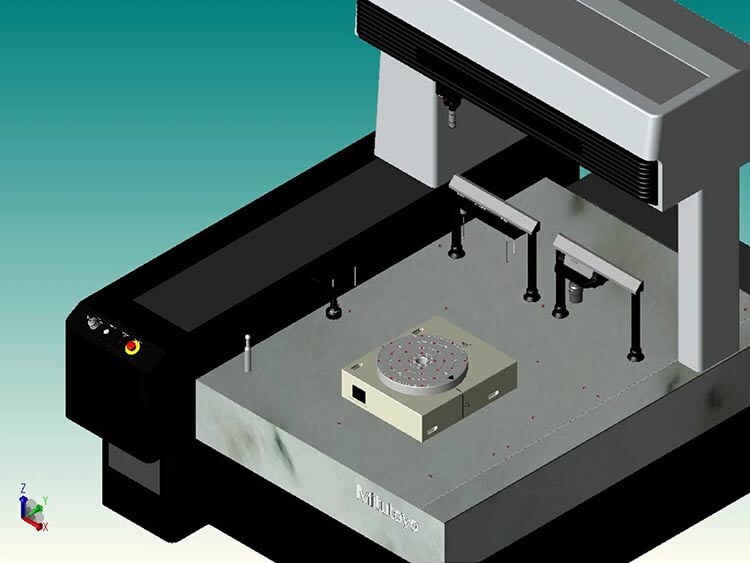

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.

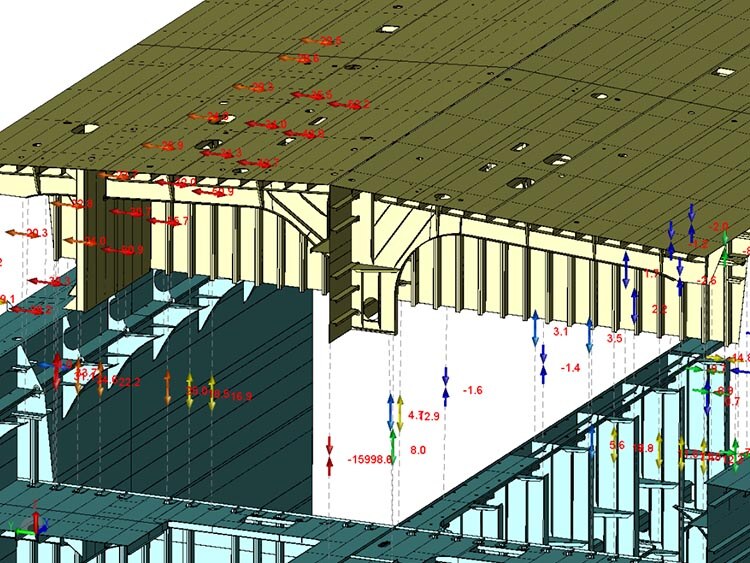

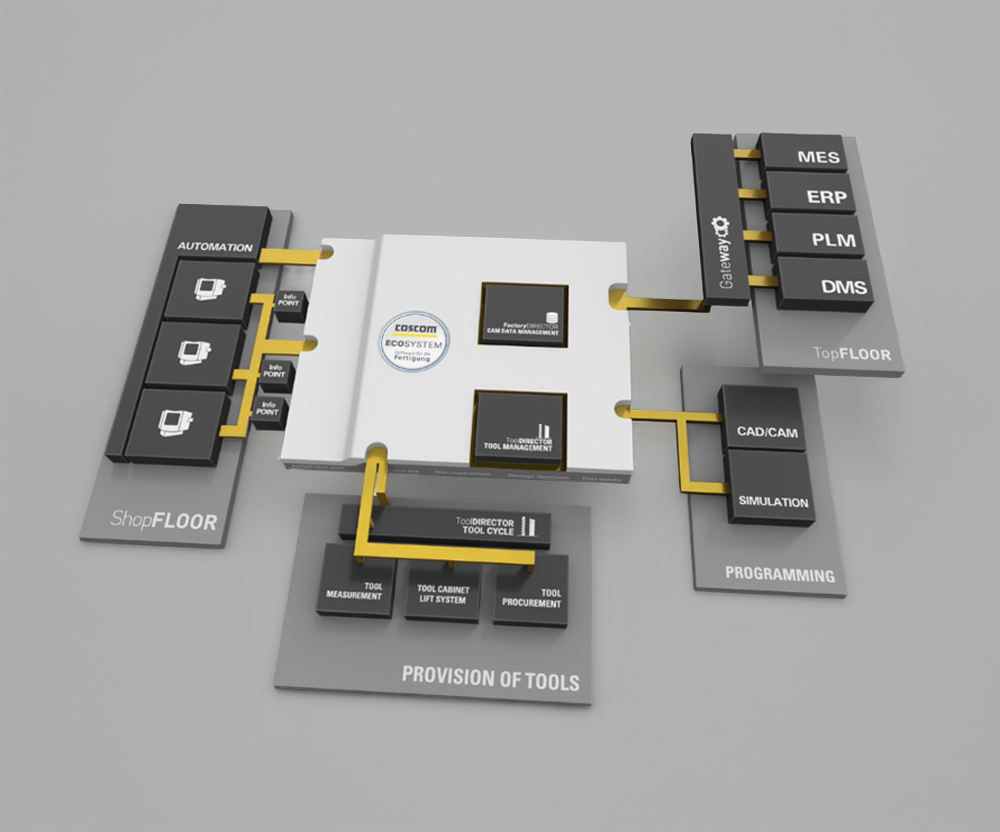

COSCOM optimized CNC Digital Twins with Intelligent CAD Data Reduction

COSCOM needed an efficient solution to manage massive CAD data volumes in their digital twin application while maintaining precision for collision detection and machine simulation in CNC machining processes.

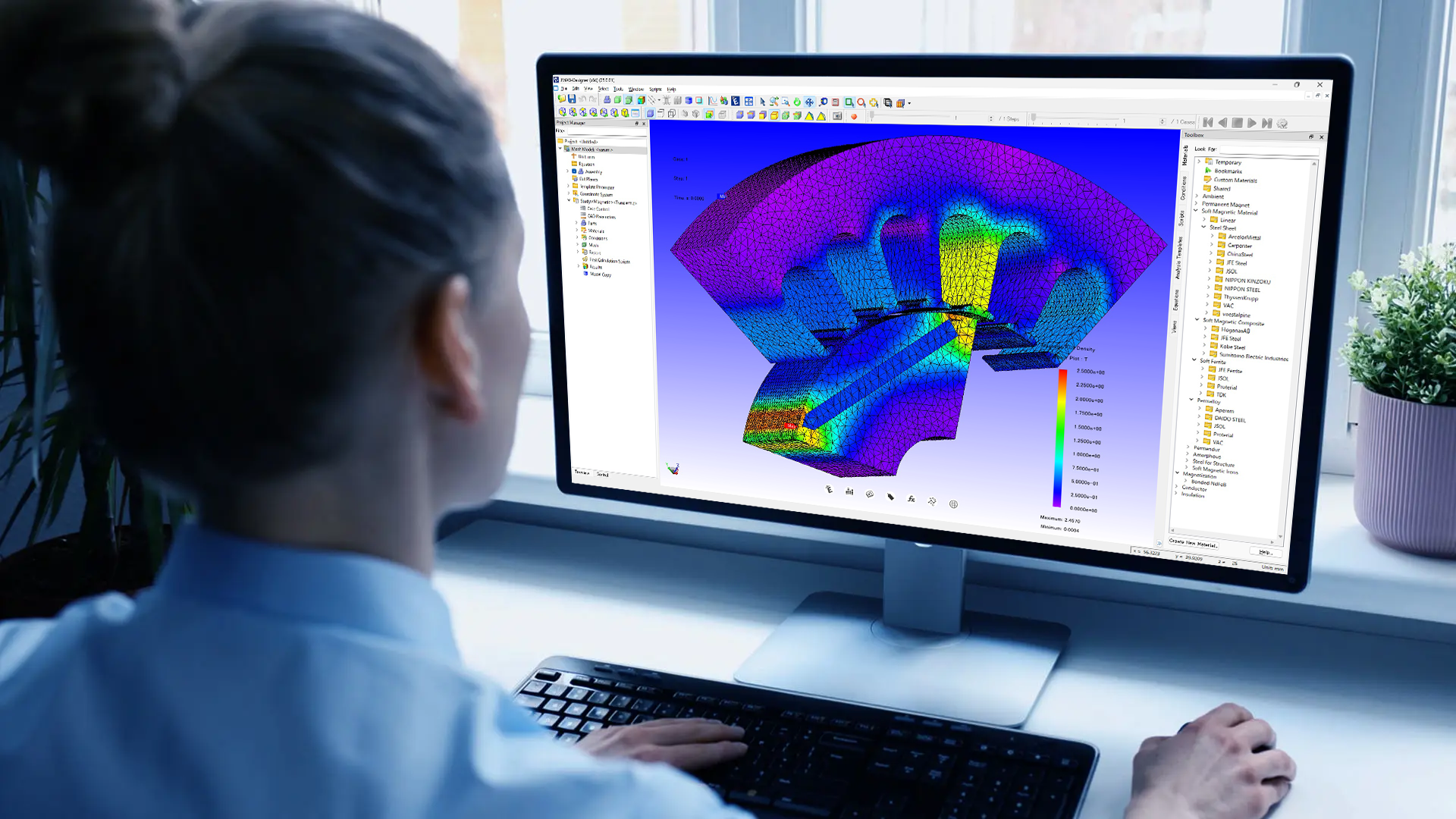

JSOL Achieved a Decade of Software Development Gains in JMAG with Integrated SDKs

JMAG, a simulation software for electromechanical design developed by JSOL CORPORATION, required 3D geometry handling, reliable CAD import across multiple formats, interactive operations, and defeaturing capabilities...