Prototek Case Study

Market: Manufacturing Services

Summary

Manufacturers looking for instant quoting capabilities for custom-manufactured parts can rely on high-quality, automated Software Development Kits from Spatial.

By leveraging Spatial SDKs to launch our Instant Quoting software, we achieved our goals efficiently and successfully launched within just seven months of signing the contract— a testament to the smooth and well- coordinated integration process.

The Company

Founded in 1987, Prototek is an American provider of rapid prototyping and low-volume production services, specializing in precision machined and sheet metal fabricated parts. Prototek’s mission is to be the leading full-service digital manufacturer providing a one-stop shop for high-mix, low-volume production and prototyping. Prototek is committed to delivering high-quality solutions with unmatched speed, ensuring their customers receive the best value, superior technology, and unwavering quality.

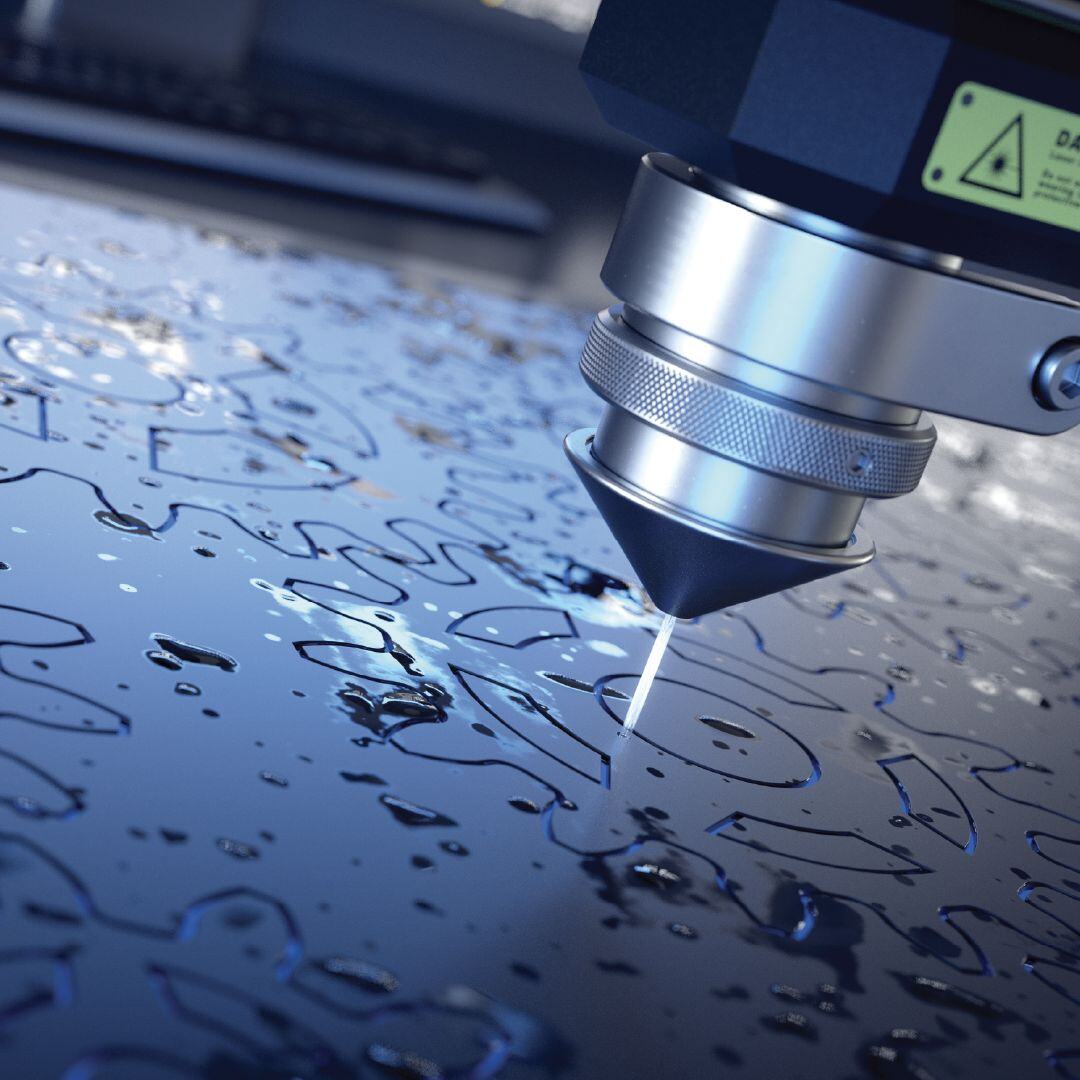

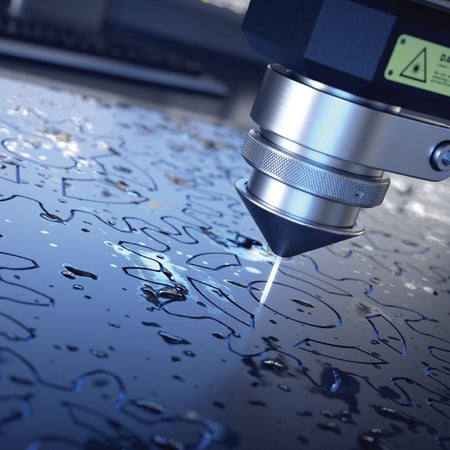

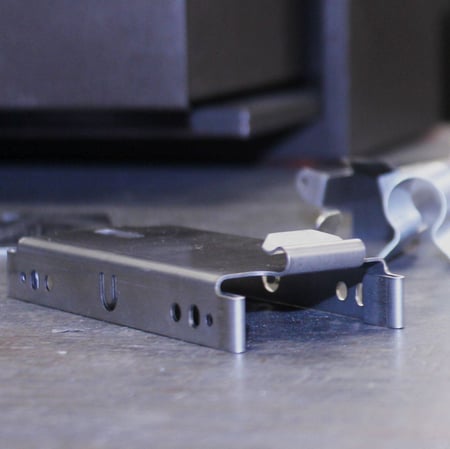

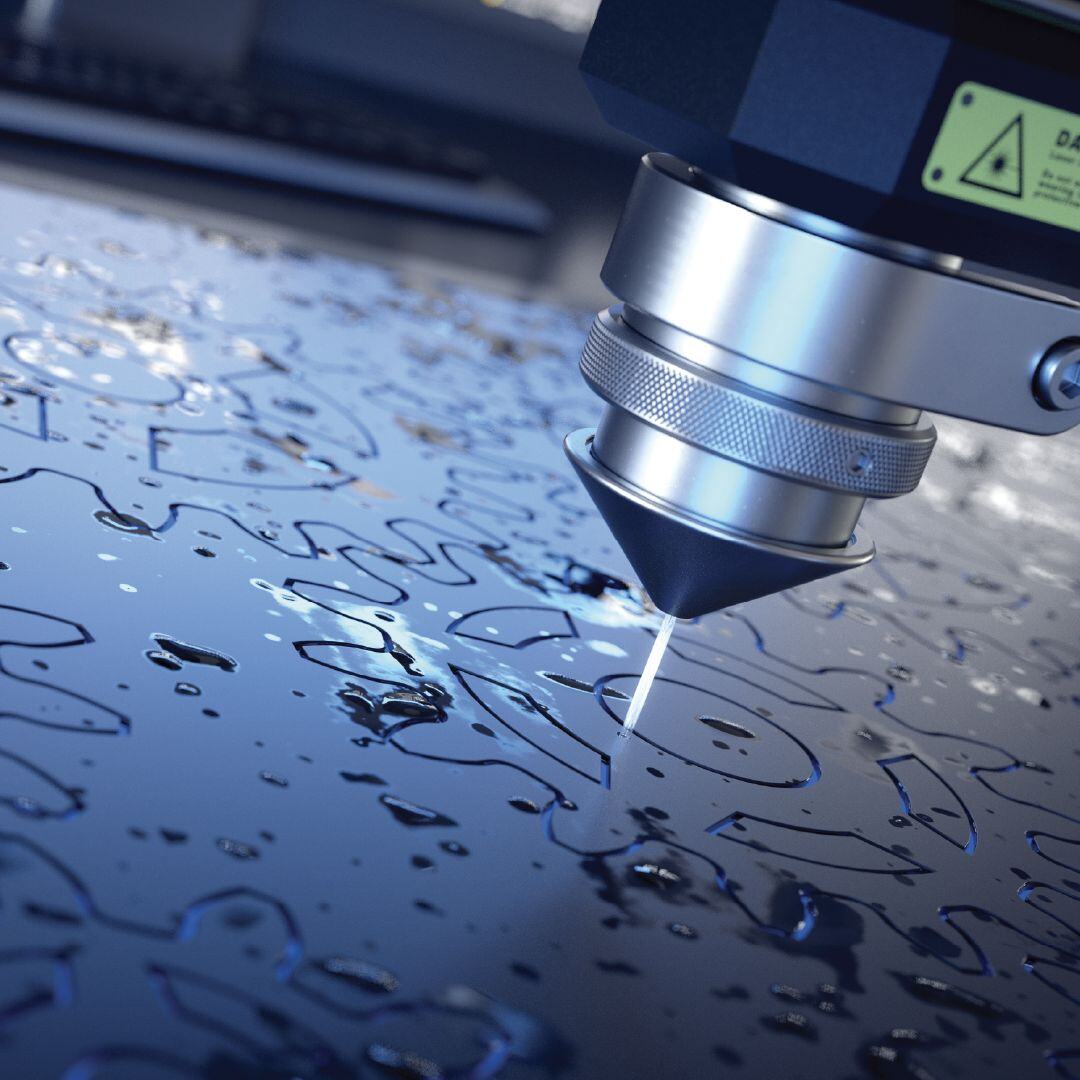

Their comprehensive services include on-demand 3D printing, CNC machining, sheet metal fabrication, casting, and molding. With a fleet of over 140 machines and multiple facilities across the United States, Prototek caters to a diverse customer base in industries such as aerospace, defense, medical, robotics, electronics, consumer, and general industrial sectors. The company stands out from the competition by offering instant and engineer-assisted quotes, 100+ choices of metal and plastic materials, 40+ surface finish options, and quality prototypes and end-use solutions

The Challenge

Implementing a robust automated quoting tool to meet industry and customer demand

As the manufacturing industry shifts to a digital future, Prototek recognized the need for digitization, automation, and speed in quoting, ordering, and production. With increasing requirements for on-demand manufacturing, customers expect seamless digital experiences. Prototek aimed to position itself as a modern, customer-centric company by developing Prototek IQ, an Instant Quote tool.

Dealing with customizable and technical components, Prototek sought to automate complex quoting processes to ensure accurate pricing based on material, design complexity, and production methods. Traditional manual quoting was slow and inefficient, often requiring back-and-forth communication. The Instant Quote feature focused on faster turnaround times, transparency, and accuracy to enhance customer satisfaction.

With competitors offering similar tools, Prototek wanted to develop its own Instant Quote feature to remain competitive and meet market expectations for convenience and speed. To accomplish their goals, they knew they needed a solid foundation of 3D software components to power their dynamic quoting tool

The Solution

Foundational software and dedicated technical support create a seamless integration process

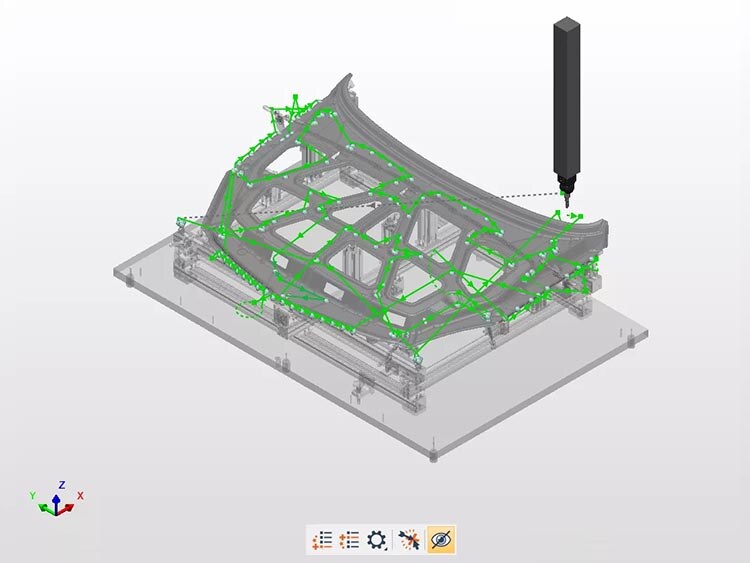

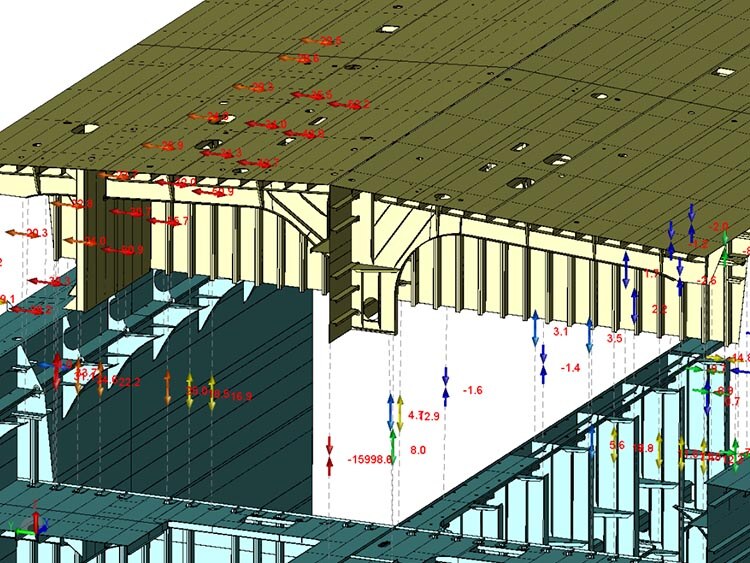

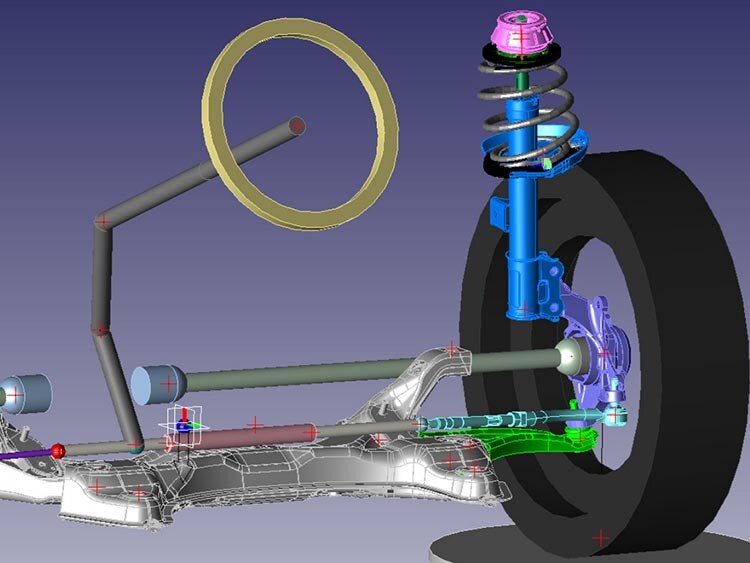

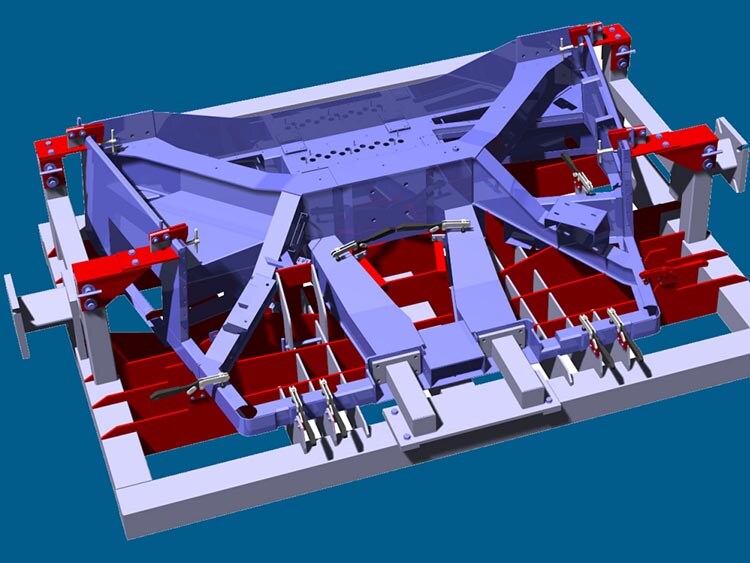

Prototek utilizes Spatial SDKs in its Prototek IQ platform, particularly for Prototek IQ-CNC and Prototek IQ-3D Printing. These components play a critical role in enhancing the well-known Prototek Instant Quote feature by enabling advanced geometry analysis, automated manufacturability checks, and precise cost estimation. This integration allows the company to provide accurate and immediate customer quotes, streamline the manufacturing process, and ensure optimal part quality.

Prototek worked with Spatial to determine the right mix of SDKs to meet their goals:

CGM Modeler empowers Prototek to automate and accelerate development with advanced features like Feature Recognition and Sheet Metal Unbending. Its robust geometric querying capabilities enable custom algorithms to generate accurate, industry-standard quotes quickly and efficiently. This industry-proven 3D kernel provides the backbone for Prototek’s quoting system.

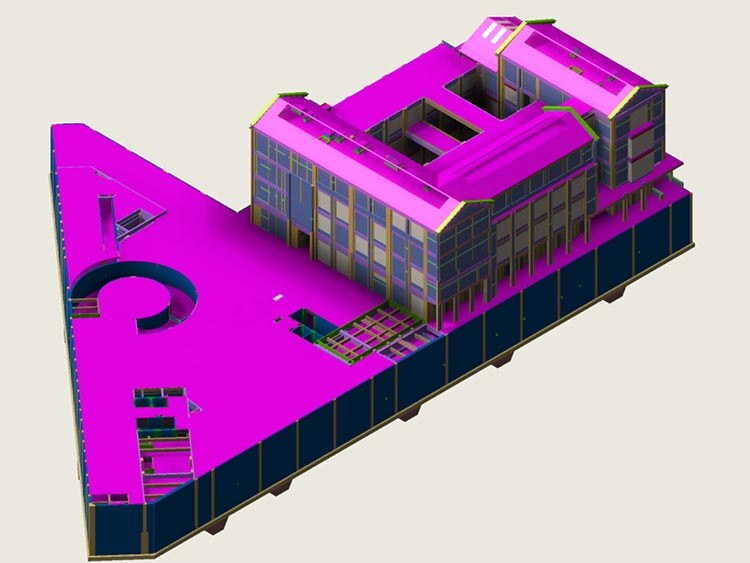

For interoperability, 3D InterOp enables an application to work with an extensive breadth of CAD formats in a seamless, unified way. 3D InterOp is the industry-leading 3D CAD data translation SDK designed to exchange visualization, exact B-rep geometry, and metadata from various CAD formats.

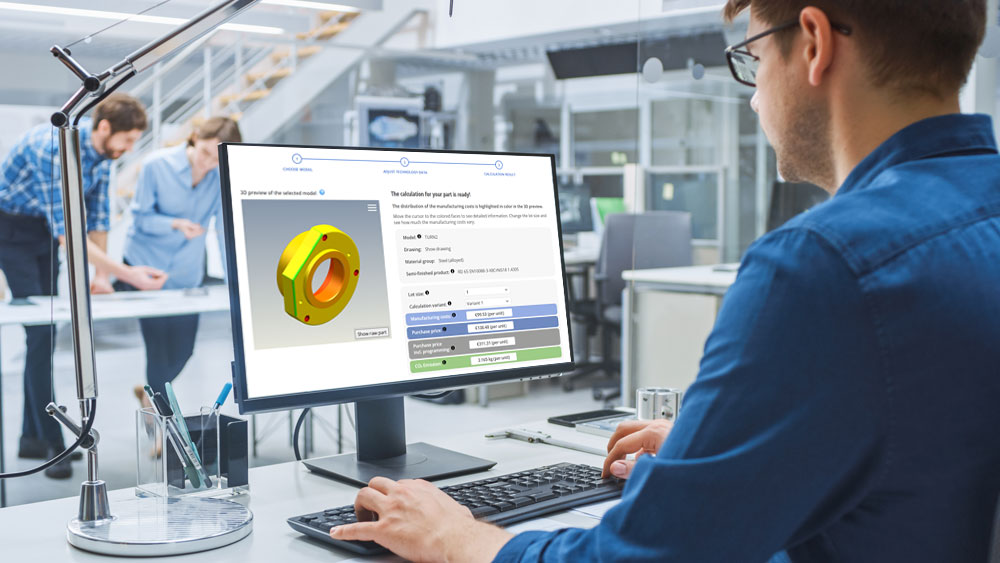

Web visualization needs are met through HOOPS Communicator, a browser-based 3D modeling and cloud CAD SDK for high-quality rendering and seamless integration in design, engineering, and manufacturing. With customizable APIs, it accelerates web app development, offering optimized performance, comprehensive 3D data access, and out-of-the-box functionality.

Spatial 3D SDKs are foundational pieces that allow Prototek IQ to instantly quote custom-manufactured parts. With the detailed documentation and example code provided within Spatial’s libraries, Prototek integrated Spatial at the ground floor level to build on top of their existing code.

Integration Process with Spatial SDKs

Spatial ensured a well-structured and collaborative integration process for Prototek. Developers at Prototek conducted a comprehensive evaluation of the Spatial SDKs during which they were supported by the Spatial Technical Account Managers (TAMs) who provided valuable guidance and expertise. Weekly calls with the TAMs allowed the team to work through any issues and bounce ideas off each other. The robust documentation and sample code provided by Spatial further enabled Prototek to quickly develop and validate a Proof of Concept that aligned with their vision.

The continuity in support and familiarity with the Spatial ecosystem allowed Prototek to quickly advance the development of their Instant Quoting software, leveraging Spatial SDKs to achieve their objectives efficiently. As a result, Prototek successfully launched its software within seven months of signing the contract with Spatial, reflecting the smooth and well-coordinated integration process.

Prototek’s integration experience highlights the value of Spatial’s comprehensive resources, technical support, and the enduring partnership with its TAMs. These factors enabled the development of innovative solutions like Prototek IQ.

Key Insights

Comprehensive SDKs empower accelerated development

By leveraging Spatial SDKs, Prototek demonstrates its commitment to innovation and excellence in digital

manufacturing, delivering seamless and efficient solutions to meet the evolving needs of its clients. Spatial’s all-in, comprehensive CAD kernel provided the robust base needed for Prototek to accelerate the development of the Prototek IQ platform. By using Spatial, in combination with Prototek-developed Machine Learning models, Prototek can accurately estimate pricing for hundreds of materials and finishes for customers’ custom-manufactured parts.

Prototek customers can now instantly procure custom manufacturing quotes online through the Prototek IQ platform, while still being able to submit traditional engineer-assisted RFQs. Getting an instant quote through Prototek IQ now takes seconds, compared to hours when done through traditional quoting methods. Customer wait time for quotes has continued to decrease dramatically, allowing customers to make quicker decisions and get their products to market faster.

The 3D modeling, interoperability, and visualization components from Spatial are part of the formula for Prototek IQ’s success as a best-in-class leader in Digital Manufacturing.

Download the Full Case Study

Want to see a more detailed breakdown of how Prototek utilized Spatial’s powerful components in their application? Download the full case study by clicking below.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

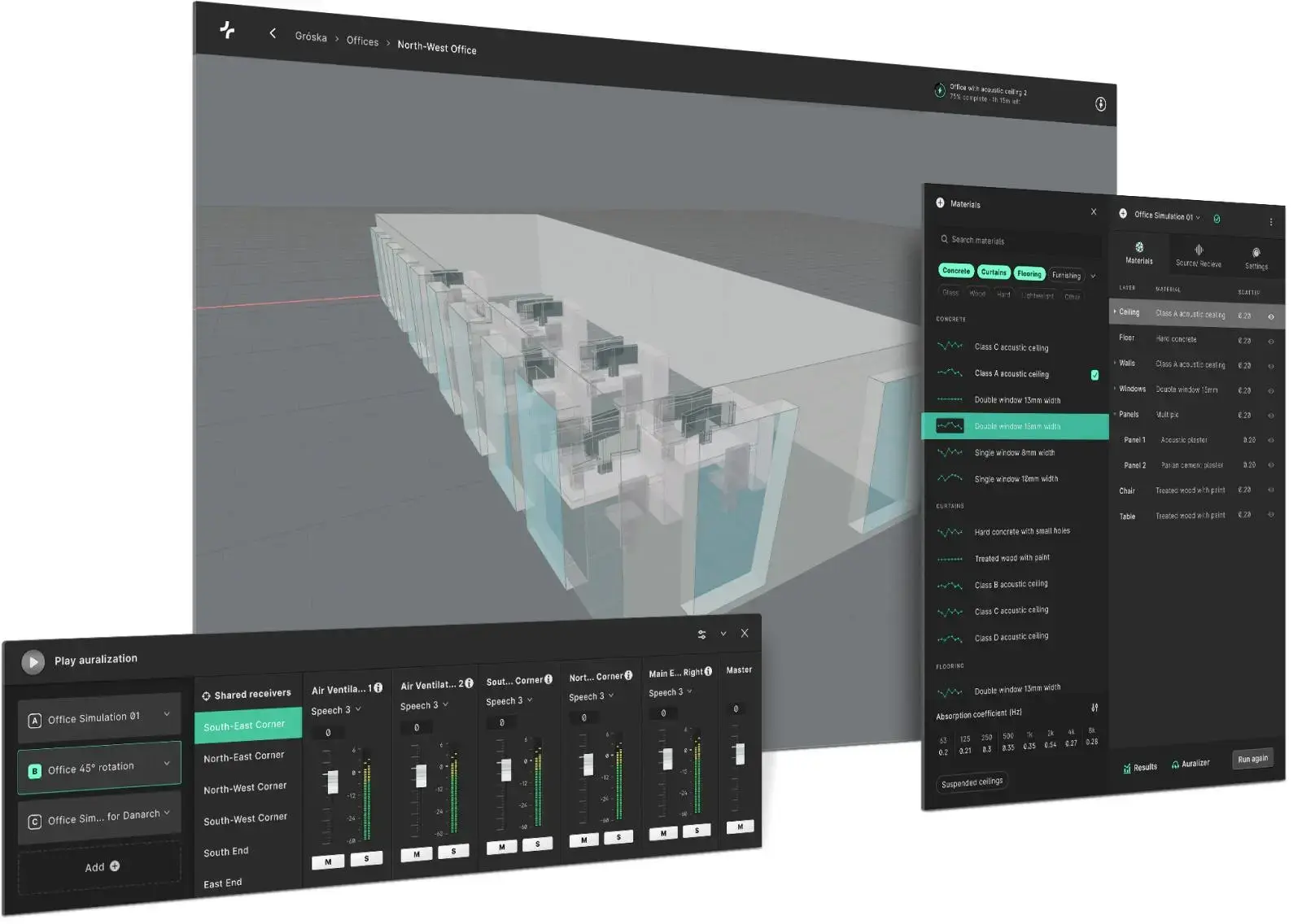

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

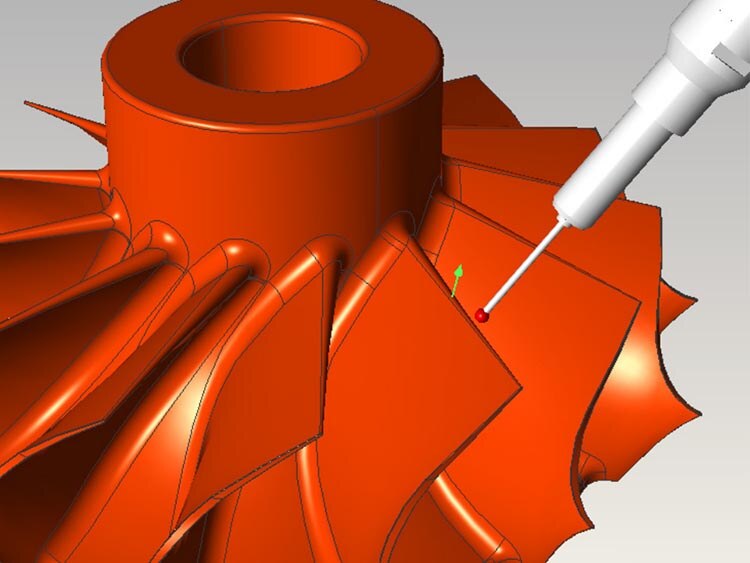

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

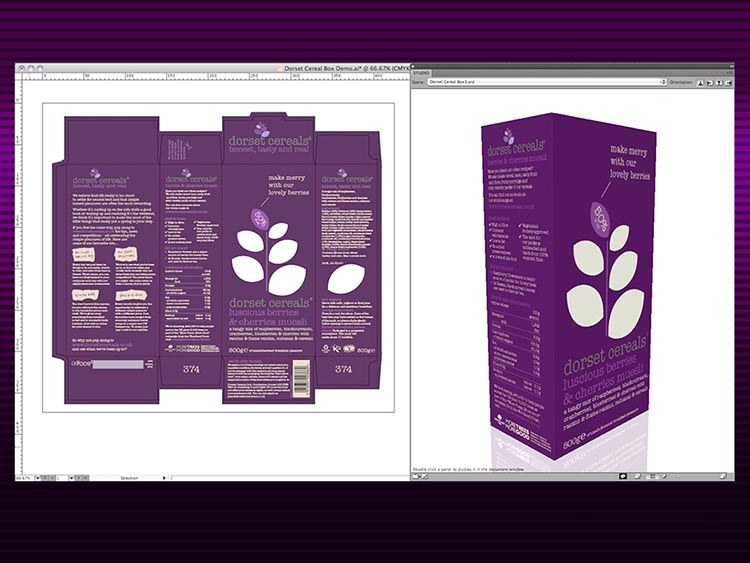

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

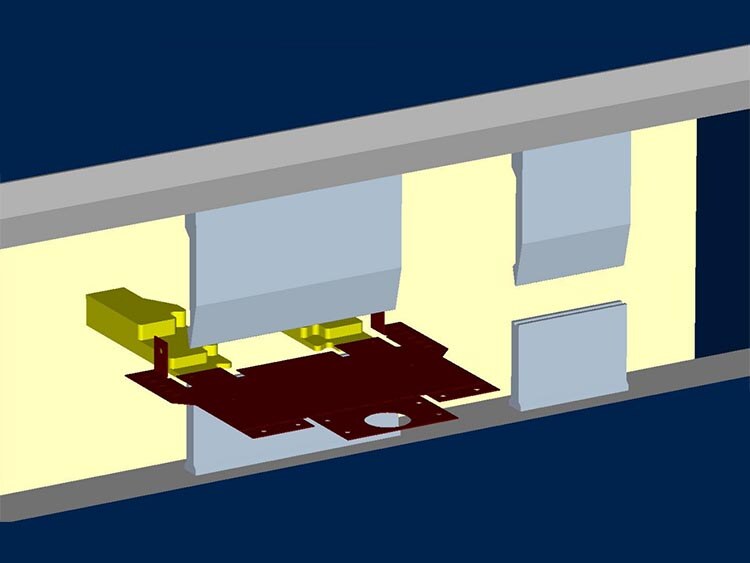

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

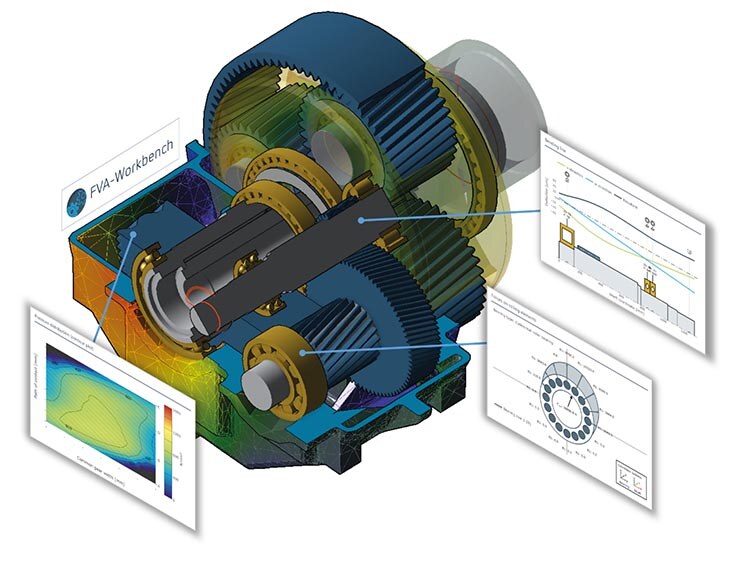

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

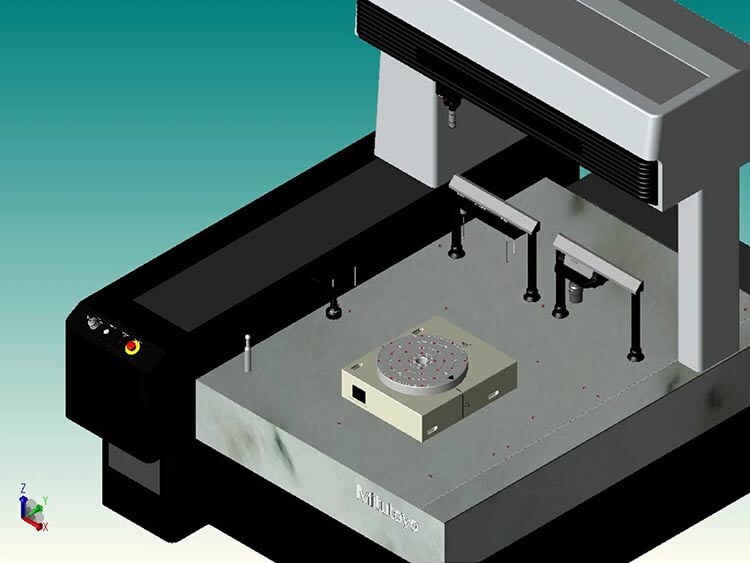

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.