Esko Artwork Case Study

Market: Structural design and manufacturing for packaging, label, sign and display applications

Summary

EskoArtwork is the global market leader in innovative design, pre-production and collaboration solutions for the packaging and commercial printing industry. They determined that they wanted the next release of ArtiosCAD to include the ability to import 3D CAD models of the products for which packaging was being designed by its customers.

Their requirement for 3D CAD import functionality led them to implement 3D InterOp for high quality file format translation.

Spatial’s CAD file format translators dramatically reduce the time it takes for ArtiosCAD users to prepare models for downstream use such as manufacturing and assembly of the final packaging articles.

The quality of Spatial InterOp Translators significantly reduced our development efforts, sped our time to market and enables us to offer a continuous workflow for structural and packaging designers.

The Company

EskoArtwork is the global market leader in innovative design, pre-production and collaboration solutions for the packaging and commercial printing industry. While headquartered in Belgium, Massachusetts is home to the company’s research and development group for its structural design CAD products. Introduced more than

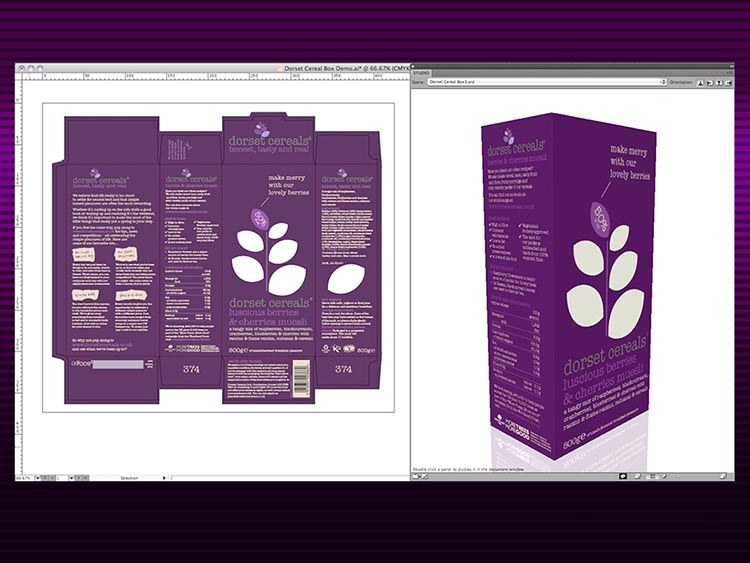

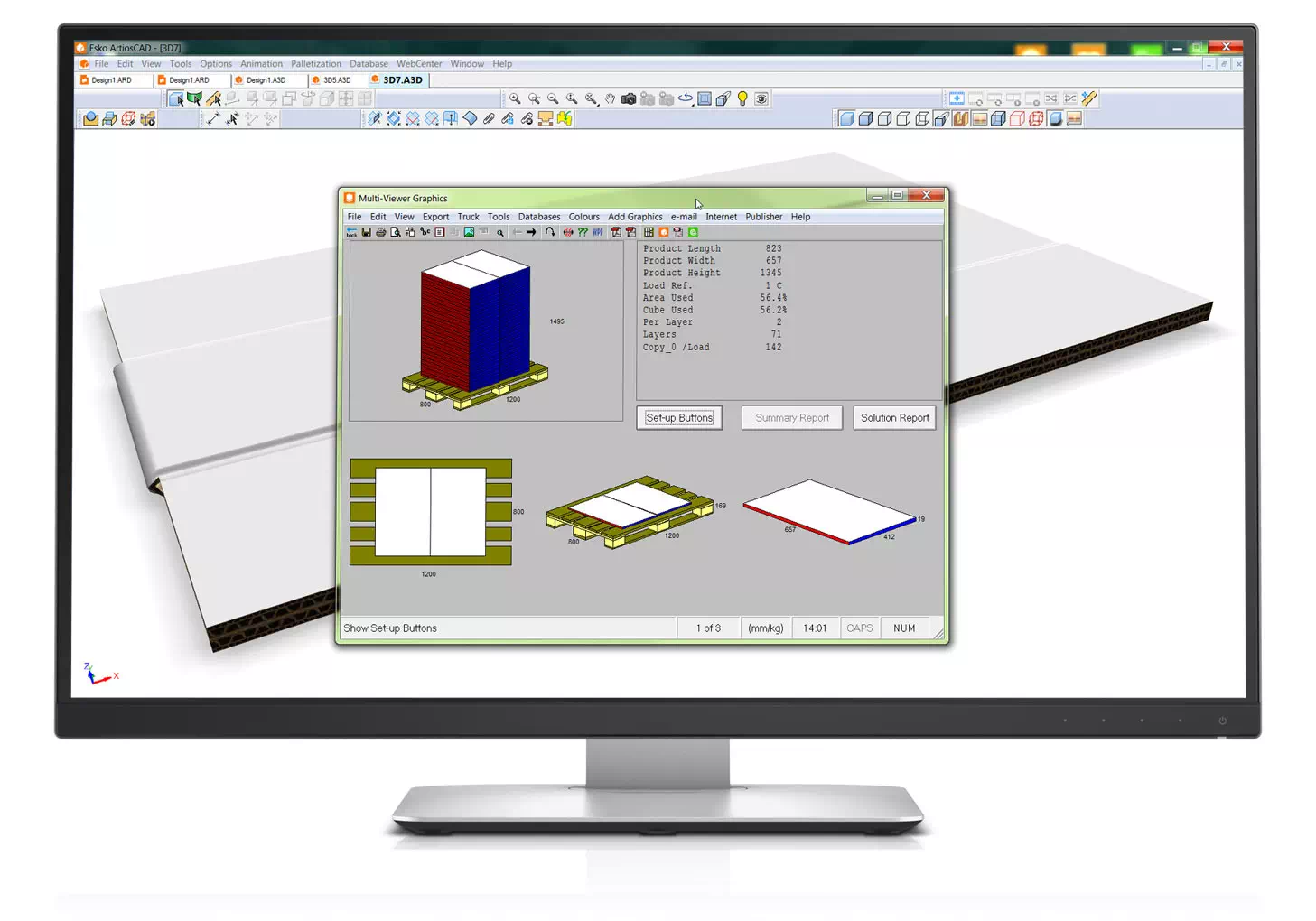

20 years ago, ArtiosCAD is EskoArtwork’s flagship product and is known throughout the package design industry for its 3D design and visualization capabilities. ArtiosCAD is used by brand owners (consumer product goods companies) folding carton converters, point of sale (POS) houses and diemakers to design structural

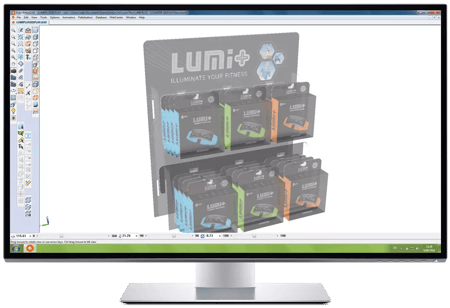

packages custom-fit to meet a variety of needs. The market for ArtiosCAD is worldwide; with the software being available in 13 different languages for a range of structural design, product development, virtual prototyping and manufacturing applications.

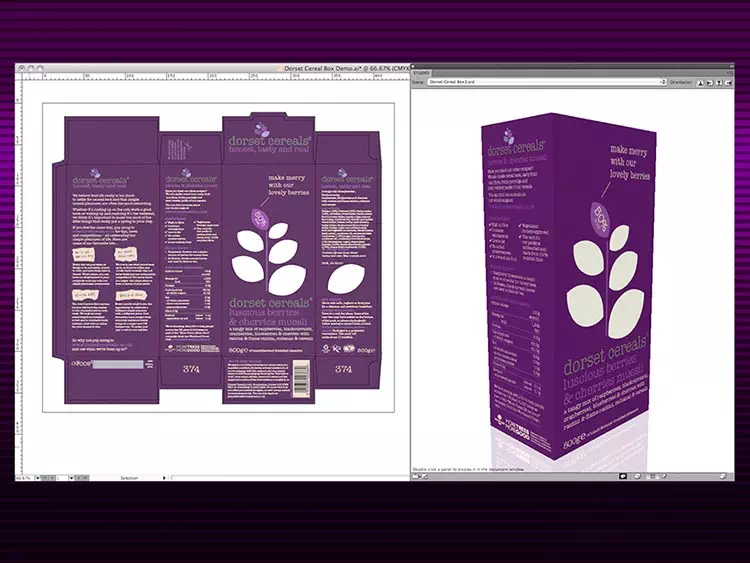

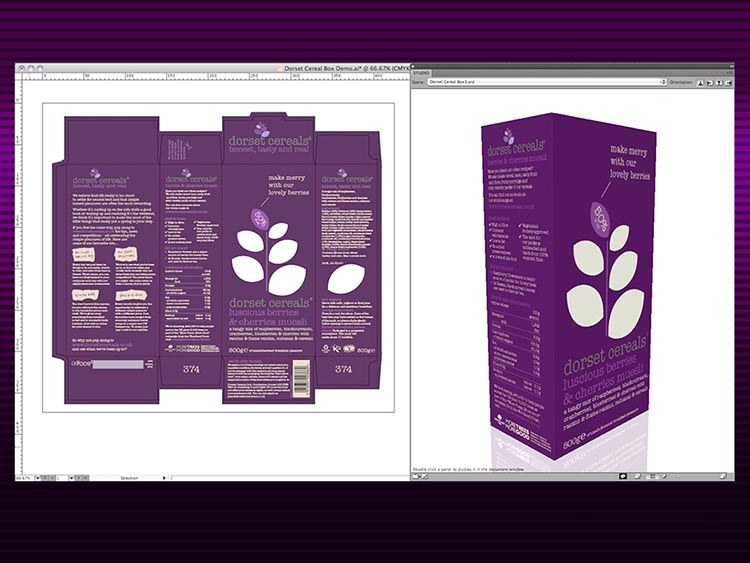

The industry-leading structural design software for packaging provides easy-to-use design features, realistic views of packaging against backgrounds and extensive support for the latest operating systems and applications. With dedicated tools specifically designed for packaging professionals, and with integration capabilities with product design software such as SolidWorks, ArtiosCAD increases productivity throughout the entire packaging supply chain, a significant reason why nearly 70% of all structural packaging worldwide is designed in ArtiosCAD.

The Challenge

A Need for 3D CAD Import Functionality

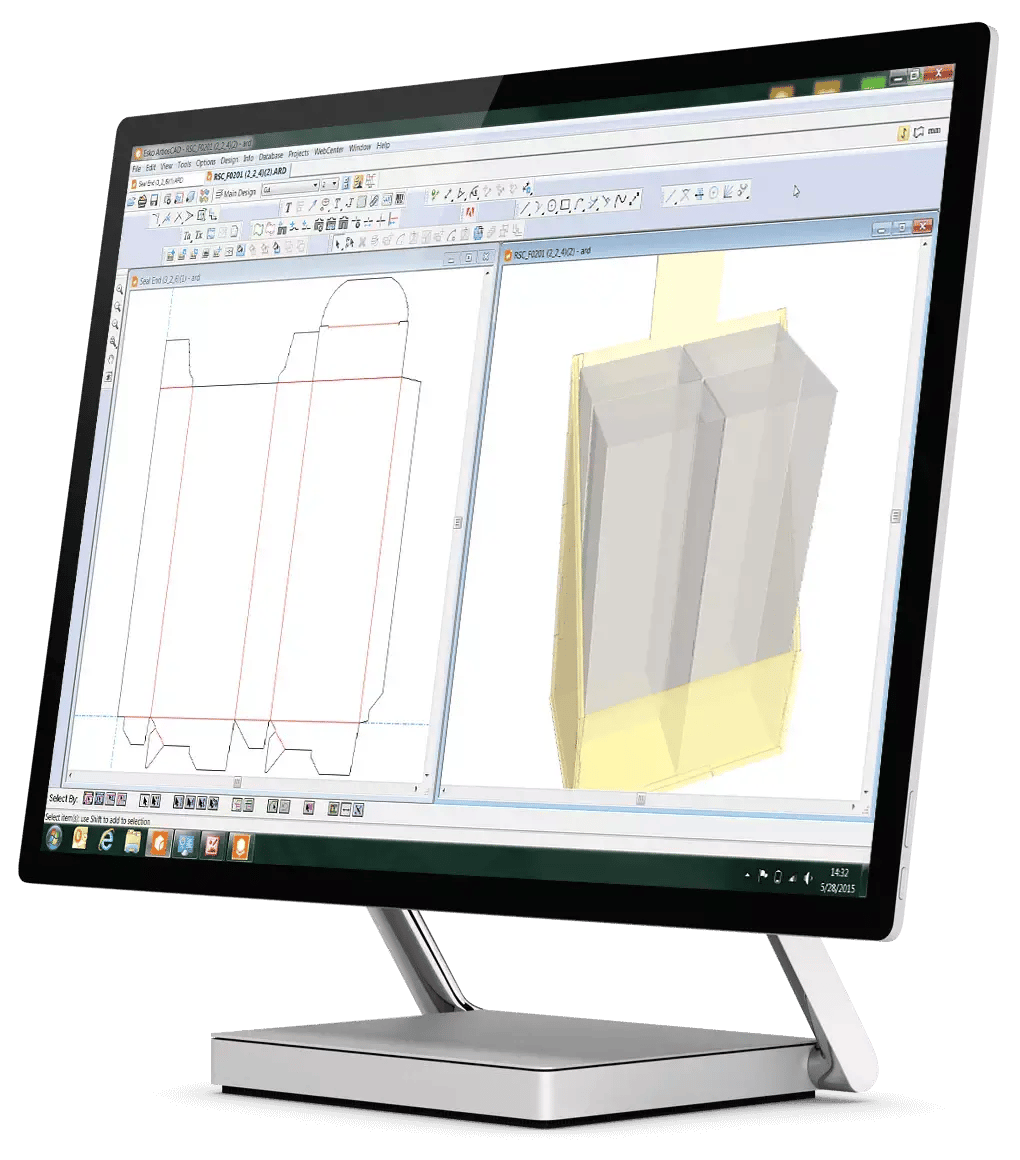

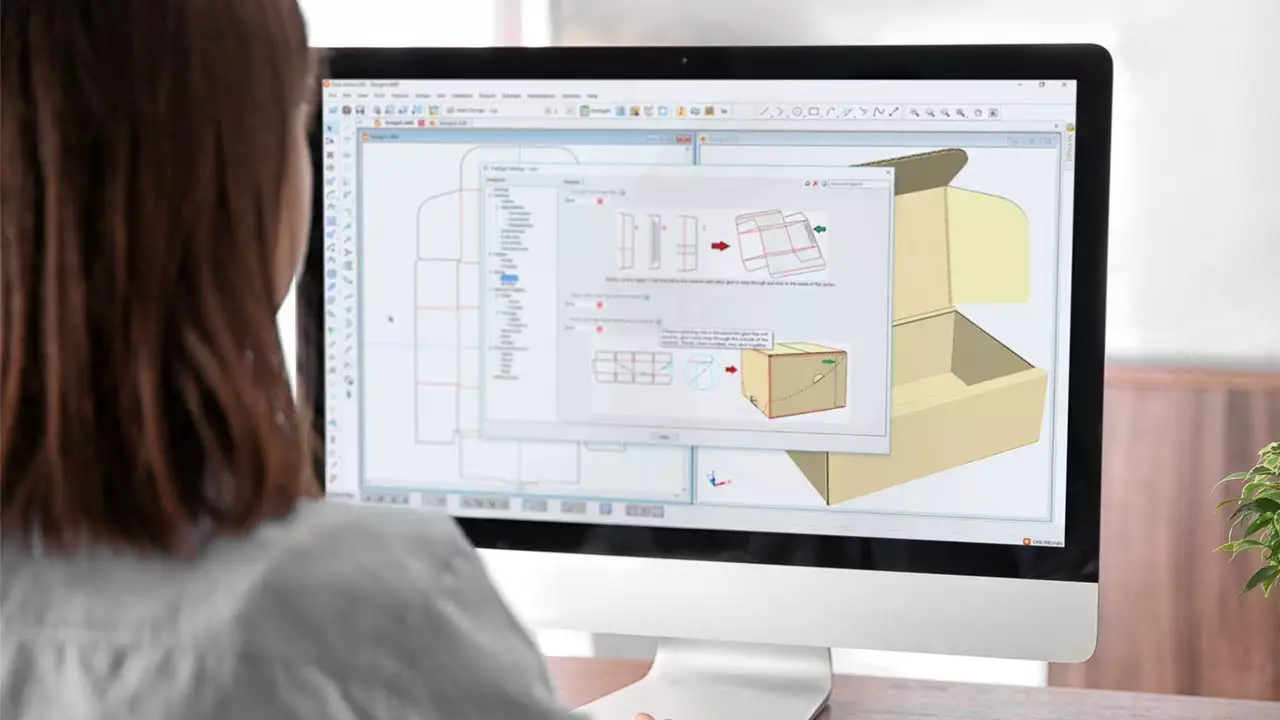

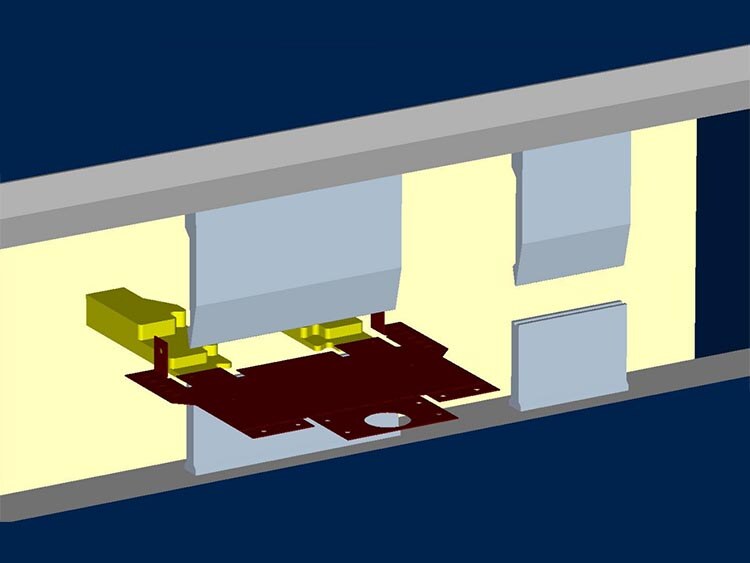

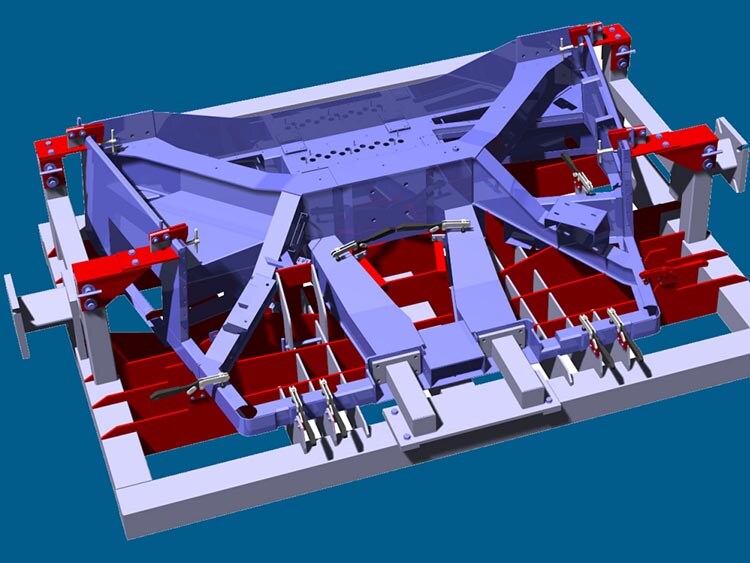

Without the ability to import 3D CAD models, structural and package designers have to manually recreate the model in 2D packaging design software. This time-consuming, laborious process is accomplished by taking measurements of the physical object’s attributes and keying in the values for all measurements, one-by-one. This is especially arduous if a cutout is needed. Then a physical sample mock-up is made to see if the object fits. If it doesn’t the process starts all over again, wasting time and material in an error-prone process.

In 2004 EskoArtwork determined that it wanted the next release of ArtiosCAD to include the ability to import 3D CAD models of the products for which packaging was being designed by its customers. This would provide significant time and cost savings for its customers and give the company a competitive edge in the market. However the company lacked the engineering resources to develop this capability in-house so it looked to a third party to source and integrate the technology.

The Solution

High Quality File Format Translation Technology

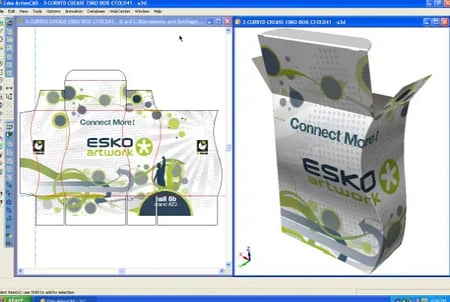

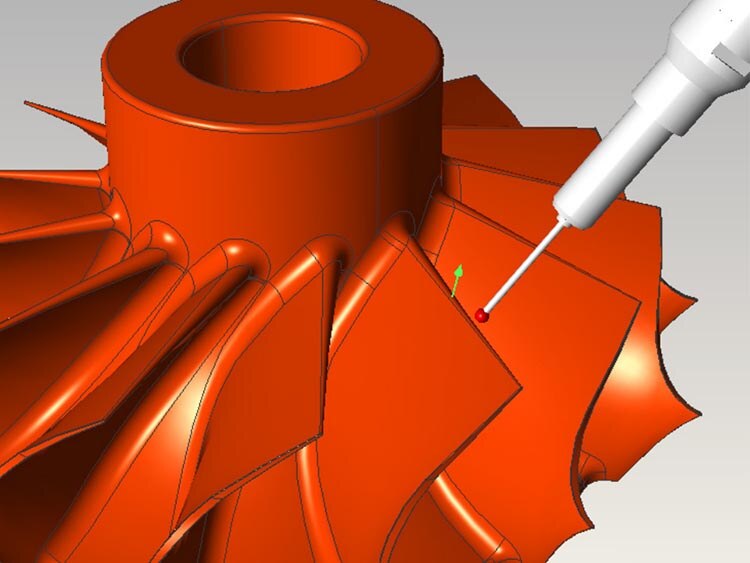

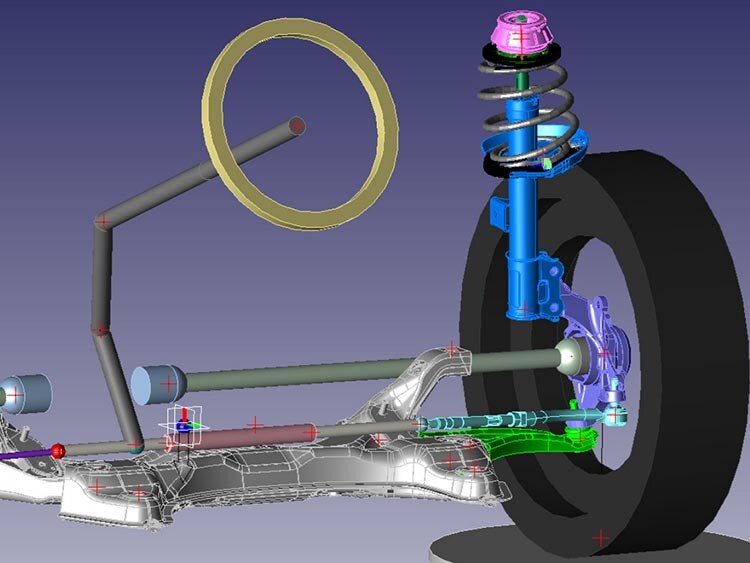

After an evaluation process, EskoArtwork selected Spatial’s high quality 3D InterOp file format translation technology to enable its customers to import 3D models from product design software packages in a range of industry-standard formats including: STEP, IGES, Pro/Engineer, Catia v4 and v5. This enables EskoArtwork’s customers to import objects into ArtiosCAD to easily design a structural package around 3D objects. The Spatial business model allows EskoArtwork to more competitively price ArtiosCAD, with Spatial sharing in the success of ArtiosCAD. “In addition, Spatial’s ability to support current CAD versions and serve as a single source, full service provider of all translators has been critical,” says Richard Deroo, EskoArtwork Product Manager.

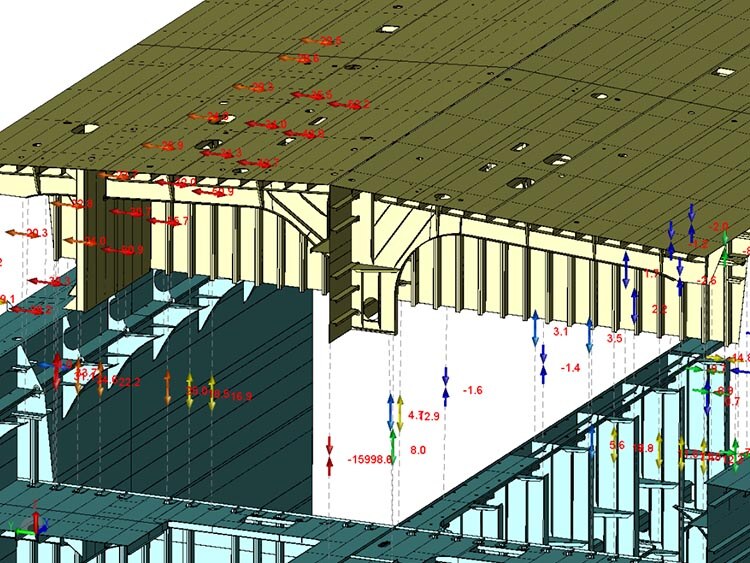

Now the company’s customers can do virtual packaging mock ups in 3D using the exact product model because all of the dimensional aspects of the product come with it in the translation. Then, ArtiosCAD provides the ability for the user to fold the box up, see if the object fits, and if it doesn’t, no wasted time and material is expended as in the previous trial and error method. Dimensions can be quickly changed to refine the fit, but most likely the packaging is going to fit by default because the user has imported an exact 3D model through the Spatial translators.

“The incorporation of the Spatial InterOp translators has been an invaluable component of ArtiosCAD,” notes Deroo. “To be able to directly import 3D objects is not only a time and cost savings, but also from a reliability standpoint, our users are virtually assured they are getting the right fit in the package from the start.”

With the actual 3D model imported into ArtiosCAD, users then “run a standard”, where a packaging template for a particular box automatically sizes right for the product. From that point the packaging designer makes modifications in terms of window cutouts, may put a secondary box around it and/or fitments – anything that’s required from a structural point of view when building the package. ArtiosCAD completes the design workflow by outputting a PowerPoint or movie file, to quickly get client feedback.

“With Spatial we never have to be concerned about the performance of their translators because Spatial provides the highest level of support,” says Deroo. Our customers are happy with the performance; and when an issue does arise, it is resolved quickly, which is essential in our industry.”

EskoArtwork started with a per seat license for each Spatial translator. In 2008 it became evident that EskoArtwork required a more flexible pricing structure because many of their customers required a full suite of CAD translators, rather than a select few. EskoArtwork opted to switch to Spatial’s 3D InterOp suite, which enabled EskoArtwork to package and price the InterOp translators according to the usage needs of their customers and the business needs of EskoArtwork.

The Results

Time-Saving Technology

The ability to import 3D file formats without the need to develop the technology internally proved critical to the development plans for ArtiosCAD. “The quality of Spatial’s suite of CAD file format translators has helped us streamline the packaging design workflow,” says Deroo. “Some of our competitors are still doing it the other way.”

Spatial’s CAD file format translators dramatically reduce the time it takes for ArtiosCAD users to prepare models for downstream use such as manufacturing and assembly of the final packaging articles.

EskoArtwork’s customers generally prefer using the native file importers such as Pro/E, CATIA V4 and V5, since these files provide higher quality translations than IGES and STEP formats can provide and eliminate any file translation errors going to an intermediate format.

“Our long-term partnership with Spatial helps us meet our aggressive product release schedule and maintain our leadership position in the market,” continues Deroo. “We don’t have to worry about keeping up with all the latest CAD file formats; Spatial ensures that we are up to date with the latest versions. In addition, InterOp’s wide range of file formats has helped us expand our penetration into consumer product companies and POP display designers.”

Key Insights

Solutions

Spatial’s high-quality CAD file format translators dramatically reduce the time it takes for ArtiosCAD users to prepare models for downstream use in manufacturing and assembly of the final packaging articles.Download the Full Case Study

Want to see a more detailed breakdown of how Esko Artwork put 3D InterOp to work for their application? Download the full case study by clicking below.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

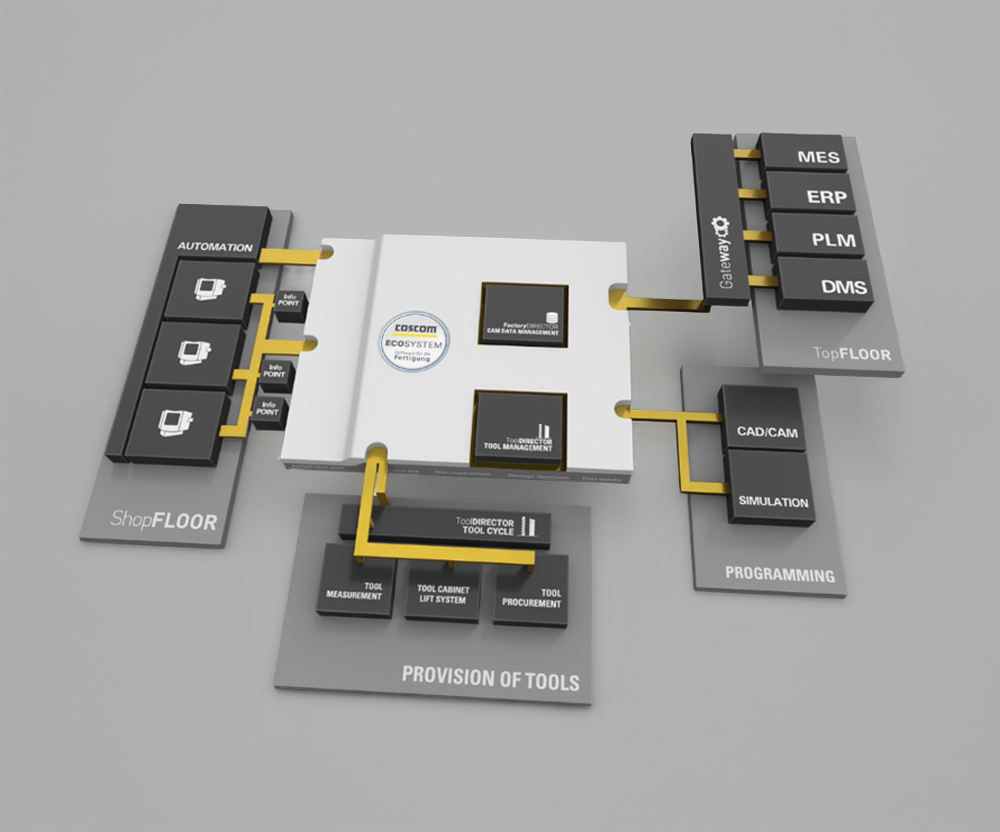

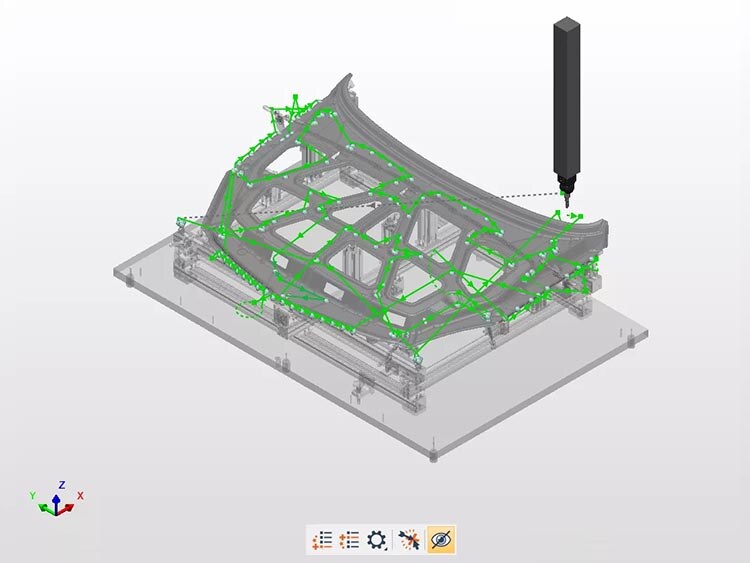

COSCOM optimized CNC Digital Twins with Intelligent CAD Data Reduction

COSCOM needed an efficient solution to manage massive CAD data volumes in their digital twin application while maintaining precision for collision detection and machine simulation in CNC machining processes.

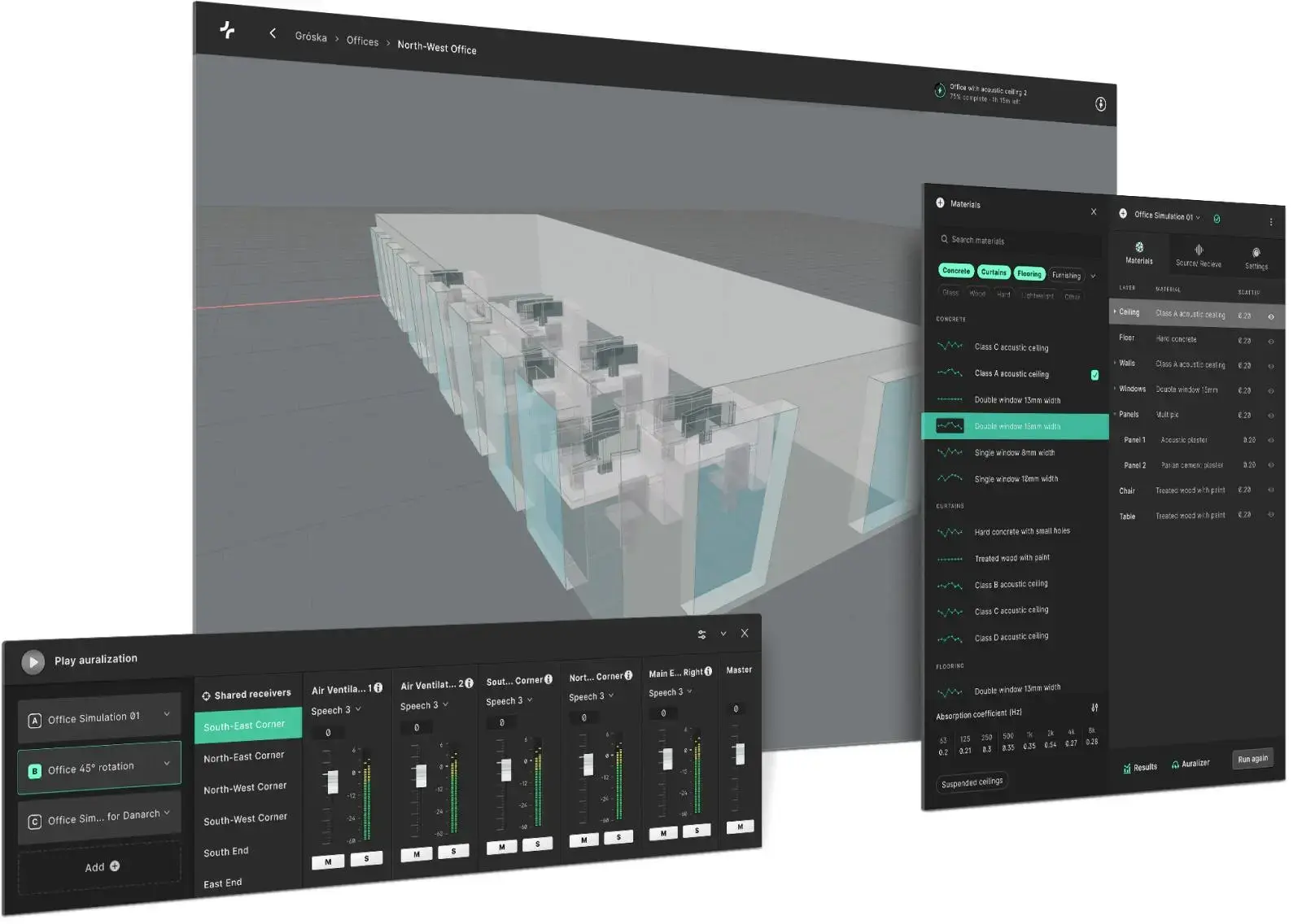

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

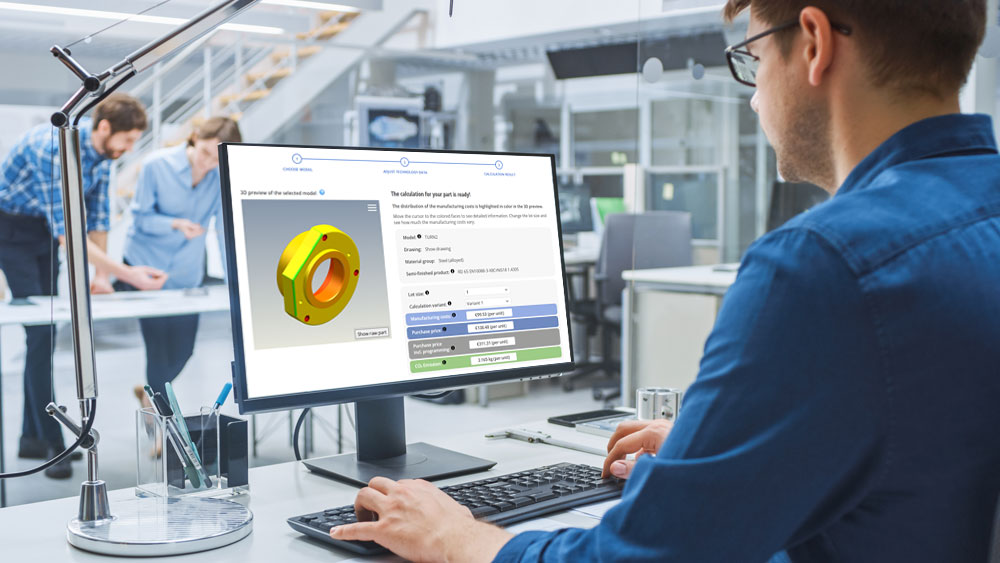

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

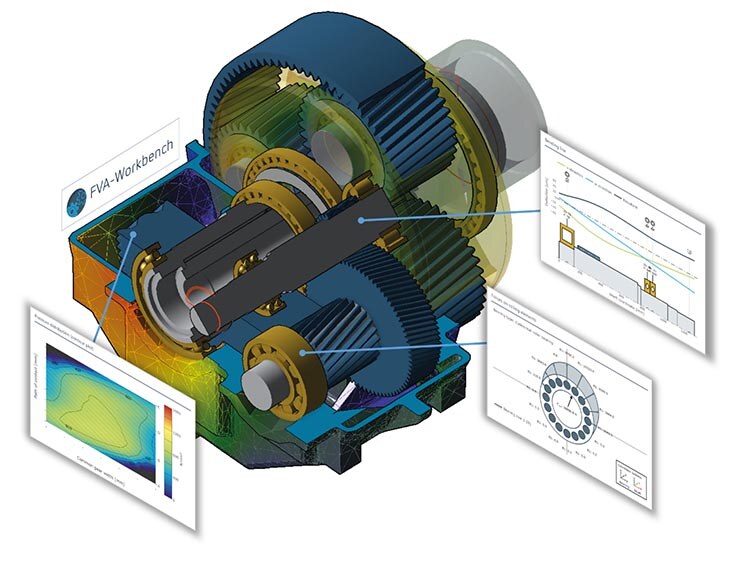

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

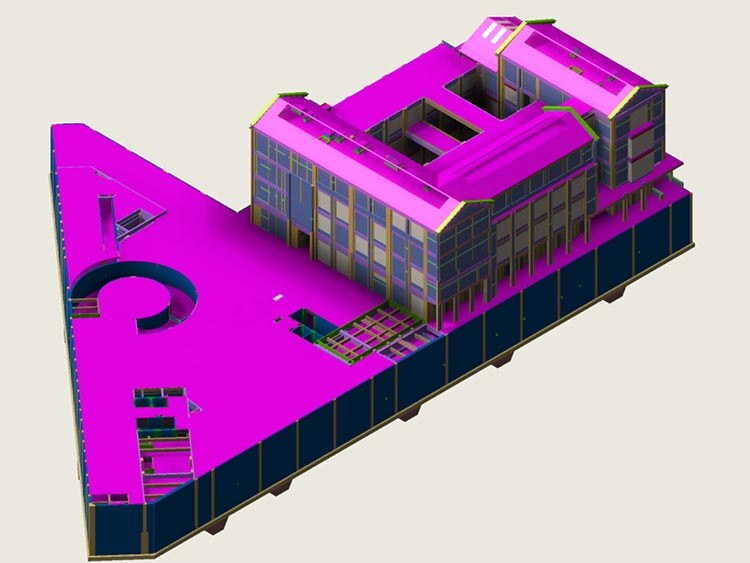

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

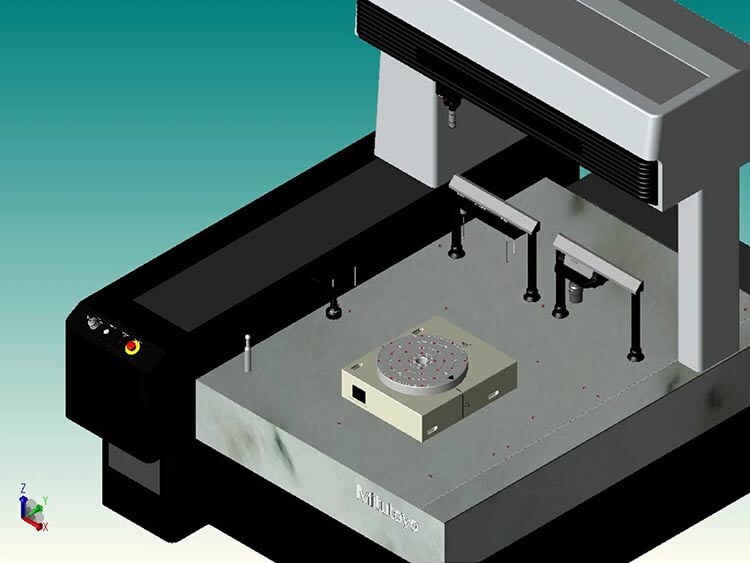

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.