Mitutoyo Case Study

Market: Metrology

Summary

Mitutoyo, a world-renowned metrology company, needed 3D modeling and translation capabilities to be competitive for their customers measuring free form surfaces and requiring accurate 3D models. To be competitive they recognized they needed superior 3D modeling and translation capabilities.

Mitutoyo found that Spatial had the best CAD integration, graphical reporting and display with their geometry kernel 3D ACIS Modeler. Mitutoyo was so pleased with the results of integrating Spatial technology into its CMM software that they recommended its use in other parts of their company.

Spatial is essential to our software and have continuously met our expectations. Without it we couldn’t be competitive in the CMM market.

The Company

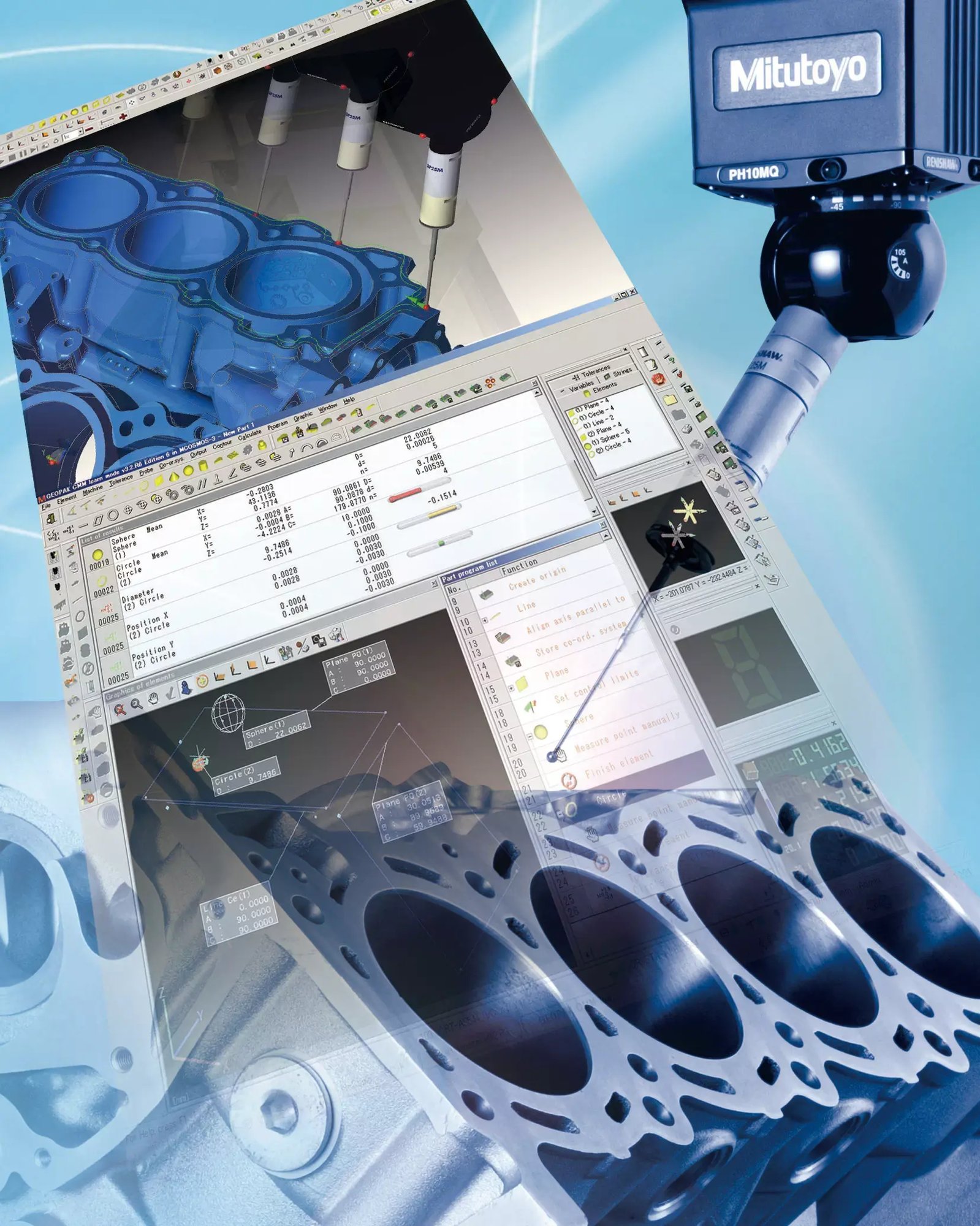

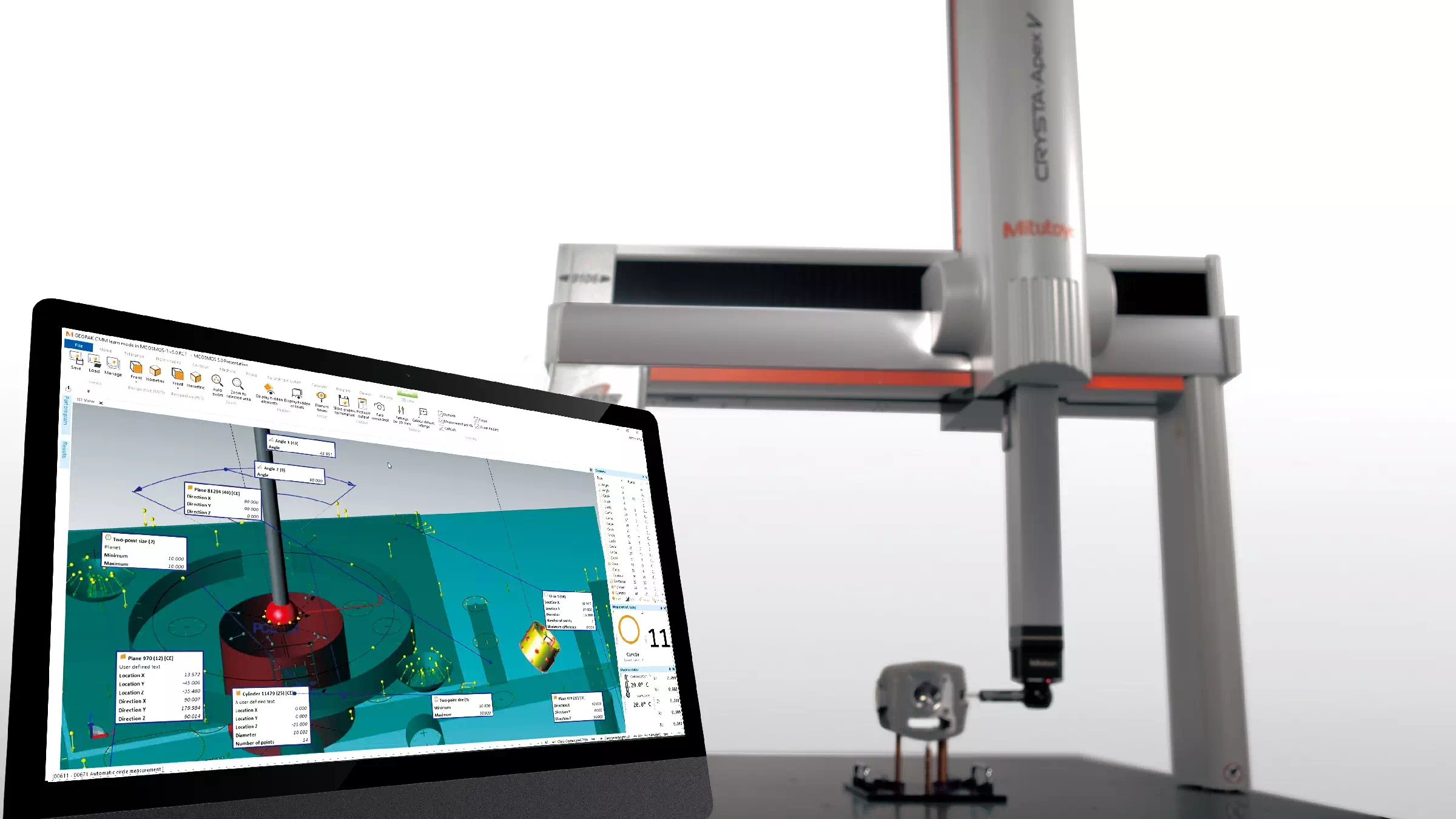

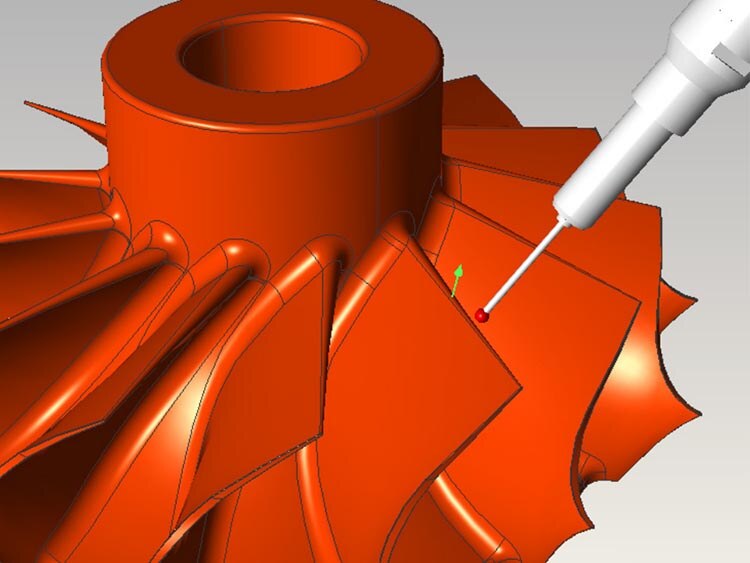

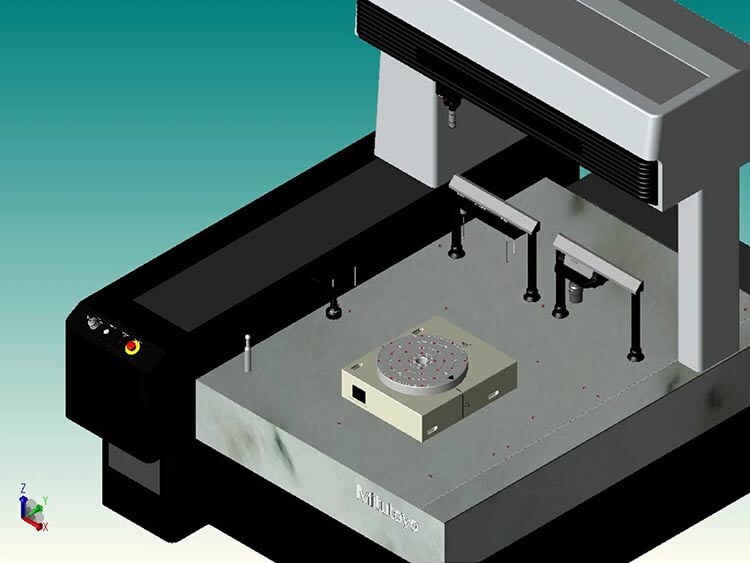

In business for 82 years, Mitutoyo has become the leading metrology company in the world with a full range of dimensional measurement tools, instruments and systems. Its MCOSMOS® coordinate measuring machine (CMM) software is the industry standard in the jet engine market. By combining highly intuitive, icon-based programming with the ability to import native CAD models, MCOSMOS enables even novice users to easily import part and fixture models and place them, on- or off-line, in a CMM.

MCOSMOS is versatile software used in a variety of applications. Mitutoyo’s two largest customers - Rolls Royce, and Blades Technology Ltd., as well as GE, Pratt & Whitney, and Lufthansa – use the CMM software to check high precision machined

parts such as turbine blades against specifications throughout each phase of the manufacturing process. At the other end of the spectrum, artists at companies such as Playmobil and Lego use MCOSMOS to construct toy parts by digitizing a design

model with MCOSMOS and making the plastic forms from the results. Other applications include automotive body parts and marine engineering.

The Challenge

Accurate 3D Models for Free-Form Surfaces

Mitutoyo’s customers needed to evaluate free-form surfaces, so the company first tried to develop IGES translation capabilities internally but wasn’t obtaining satisfactory results. It realized that to be competitive it needed superior 3D modeling and translation capabilities.

Mitutoyo developers excel at creating software that manages part programs and evaluates the coordinate data in specifications against the CAD models, but it lacked the expertise to develop a geometry modeling engine and CAD data translators internally.

The Solution

Suite of High-Quality 3D Solutions

Back in 1994 when initially designing the functionality for MCOSMOS, Mitutoyo product managers realized they lacked the experience and manpower to develop the underlying modeling engine to support working with its customers’ CAD modeling data. Their customers were measuring free form surfaces such as turbine blades which aren’t described by any basic geometry. Initially the company was doing the translation internally and tried to display measurement results with its own tools, but it proved to be unsatisfactory.

Mitutoyo found that Spatial had the best CAD integration, graphical reporting and display. “Something comparable was not available from any other company which is why we decided to choose Spatial,” says Dr. Ing. Dieter Loebnitz, Director Software Development at Mitutoyo.

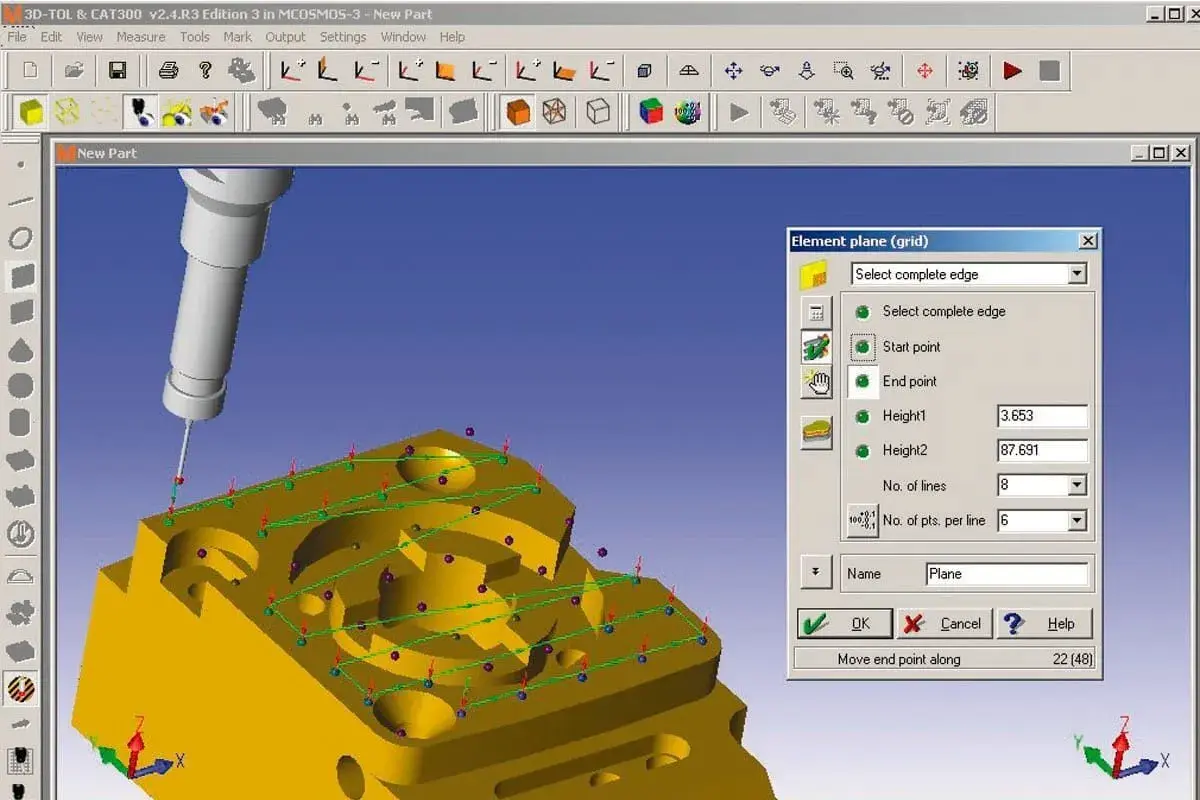

MCOSMOS undergoes continuously ongoing development with new releases every year or two with added functionality, different probing strategies and measuring features, all determined by customer input. More than ten developers (in Germany and Los Angeles) directly work with 3D ACIS Modeler-related aspects of the program.

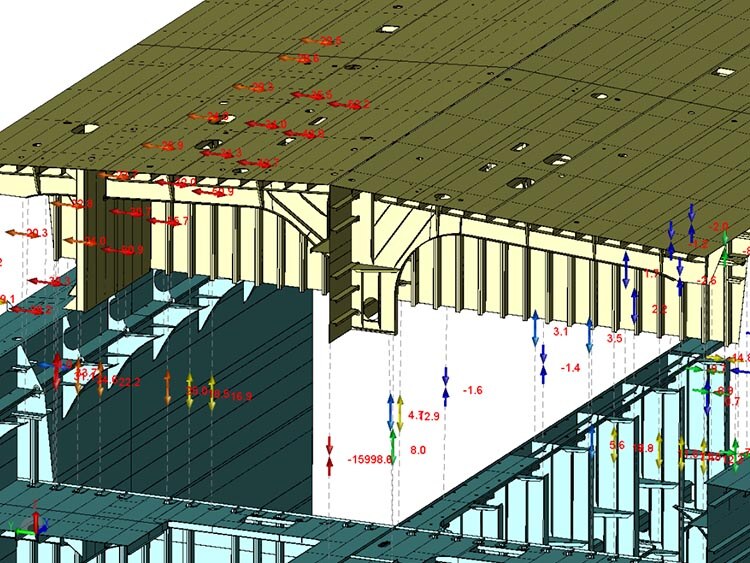

Thanks to Spatial’s comprehensive 3D InterOp software development toolkit, MCOSMOS accepts IGES, VDA-FS, and STEP CAD formats; as well as Spatial’s 3D ACIS Modeler and Siemens Parasolid. HOOPS Visualize is used for all of the software’s graphical reporting, such as color shaded services to depict deviations from the ideal model.

The Results

A Broad Use of Spatial SDKs

Throughout the years, Loebnitz has seen many benefits to incorporating Spatial’s technology into MCOSMOS, including the ease of programming measurement sequences for its CMMs. In addition, HOOPS provides Mitutoyo’s users elegant visualization of measurement data and graphical reporting.

What aspect of Spatial’s technology has proven most critical to the success of MCOSMOS? Loebnitz points to the efficiency of the 3D InterOp translators, the speed of which have improved quite a lot over time, in terms of display time, especially important with today’s models that are measured in gigabytes rather than megabytes. Large models that used to take a few hours to be read in, now take mere minutes.

Future functionality will include adding product manufacturing information such as tolerance information from the CAD model to the CMM, which wouldn’t be possible without Spatial. Loebnitz credits its close partnership with Spatial as instrumental to making this possible. “This is a new development that has great future potential for us,” notes Loebnitz.

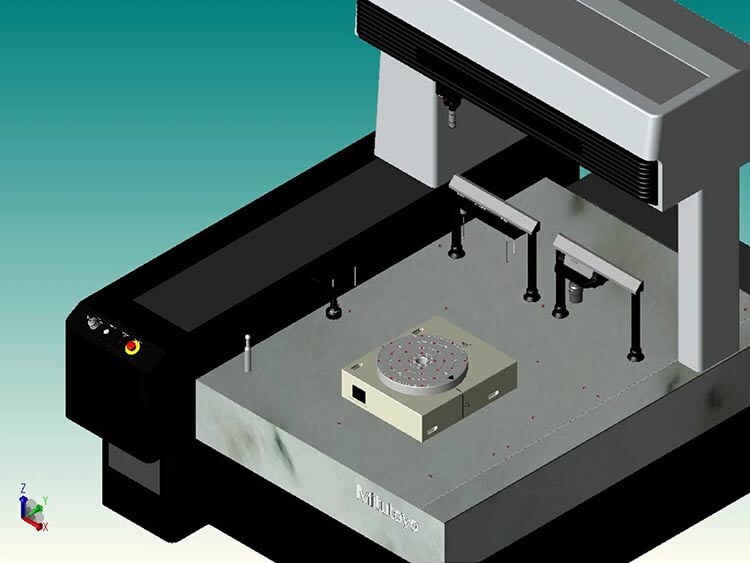

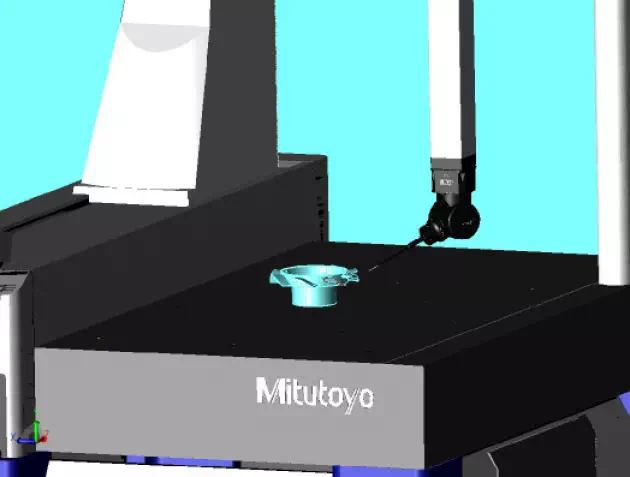

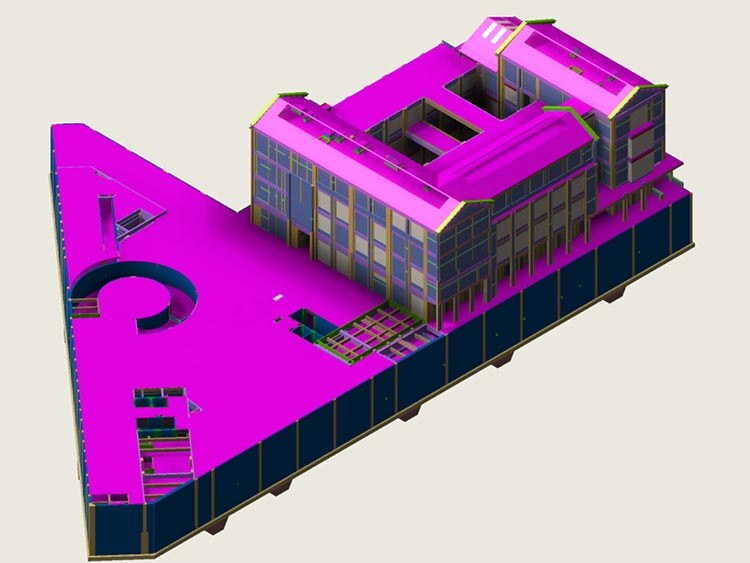

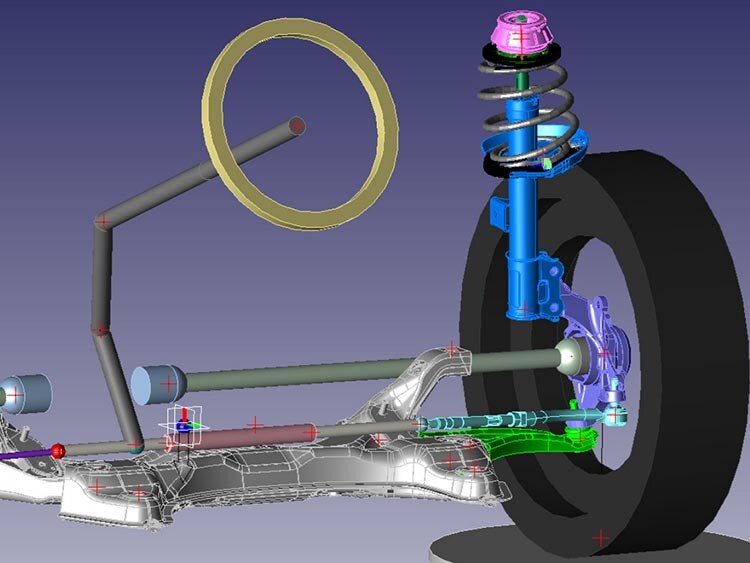

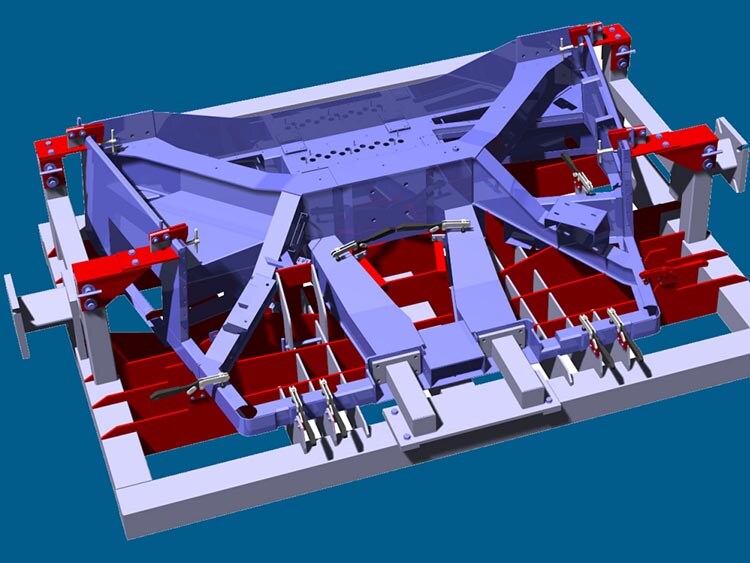

Mitutoyo was so pleased with the results of integrating Spatial technology into its CMM software that they recommended its use in other parts of their company. For example, in machine configuration, Spatial facilitates having a complete offline system where the user can simulate the process of measuring. This provides a huge cost savings because the user can make measurement sequences using the CAD model prior to the actual part being manufacturing.

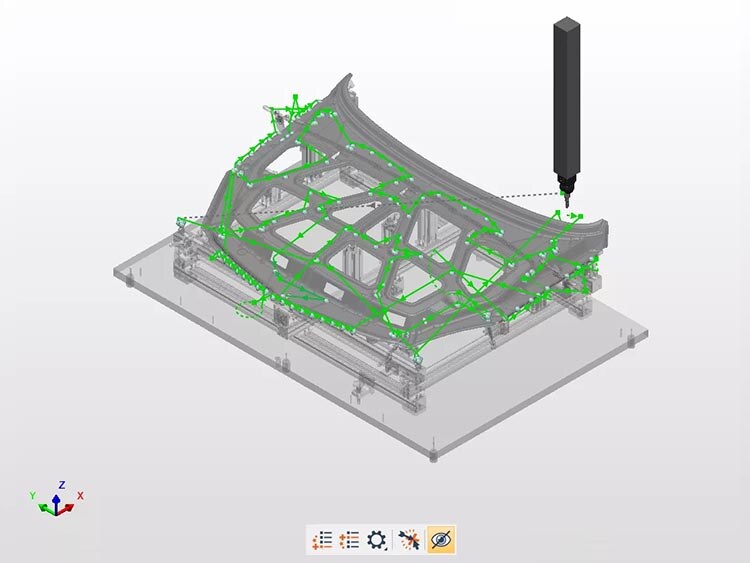

For offline programming Mitutoyo uses Spatial’s 3D ACIS Modeler and HOOPS Visualize. For the complete simulation the operator needs to visualize the rest of the machining to see how the machine moves, for example where it changes its tools.

Without Spatial’s technology, to show this sequence, the user would have to construct his own machine. Mitutoyo’s Machine Builder, a CMM configuration program, allows the user to use his machine as a model and place the CAD model of the part on it for programming and simulation, saving time and money.

Key Insights

Solutions

Mitutoyo selected Spatial’s 3D ACIS Modeler in 1994; then subsequently integrated 3D InterOp for its high-end CAD data translators, and HOOPS Visualize for more robust graphics functionality.Download the Full Case Study

Want to see a more detailed breakdown of how Mitutoyo incorporated Spatial’s SDKs into their application? Download the full case study by clicking below.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

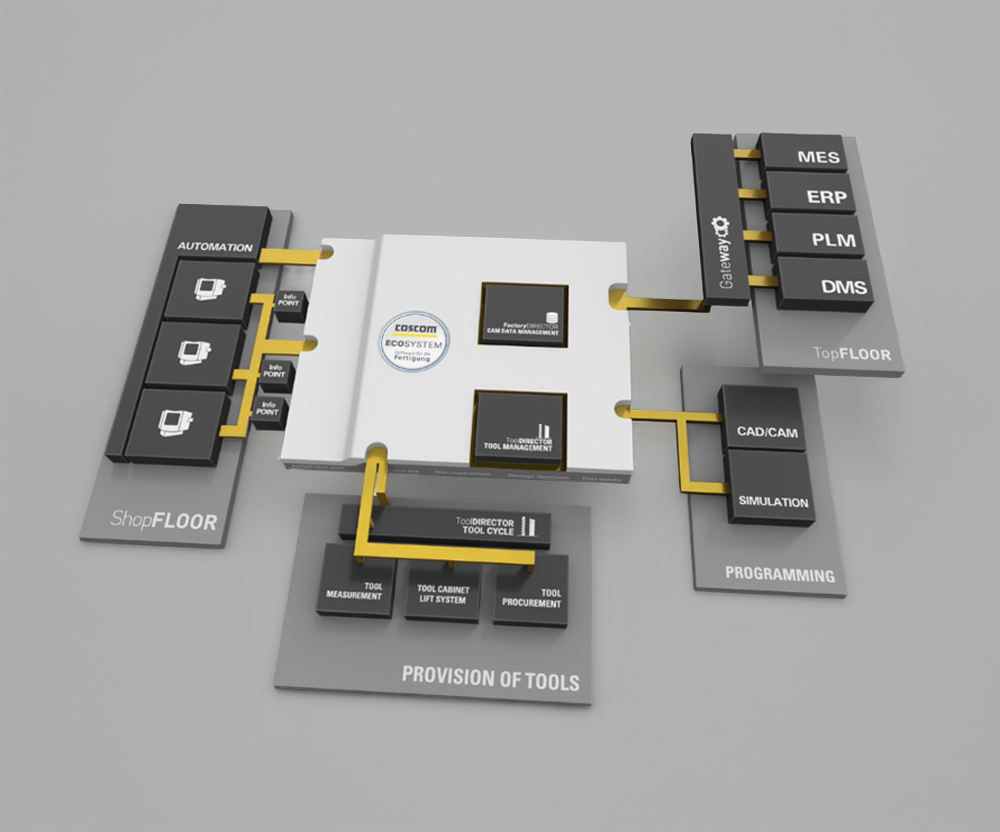

COSCOM optimized CNC Digital Twins with Intelligent CAD Data Reduction

COSCOM needed an efficient solution to manage massive CAD data volumes in their digital twin application while maintaining precision for collision detection and machine simulation in CNC machining processes.

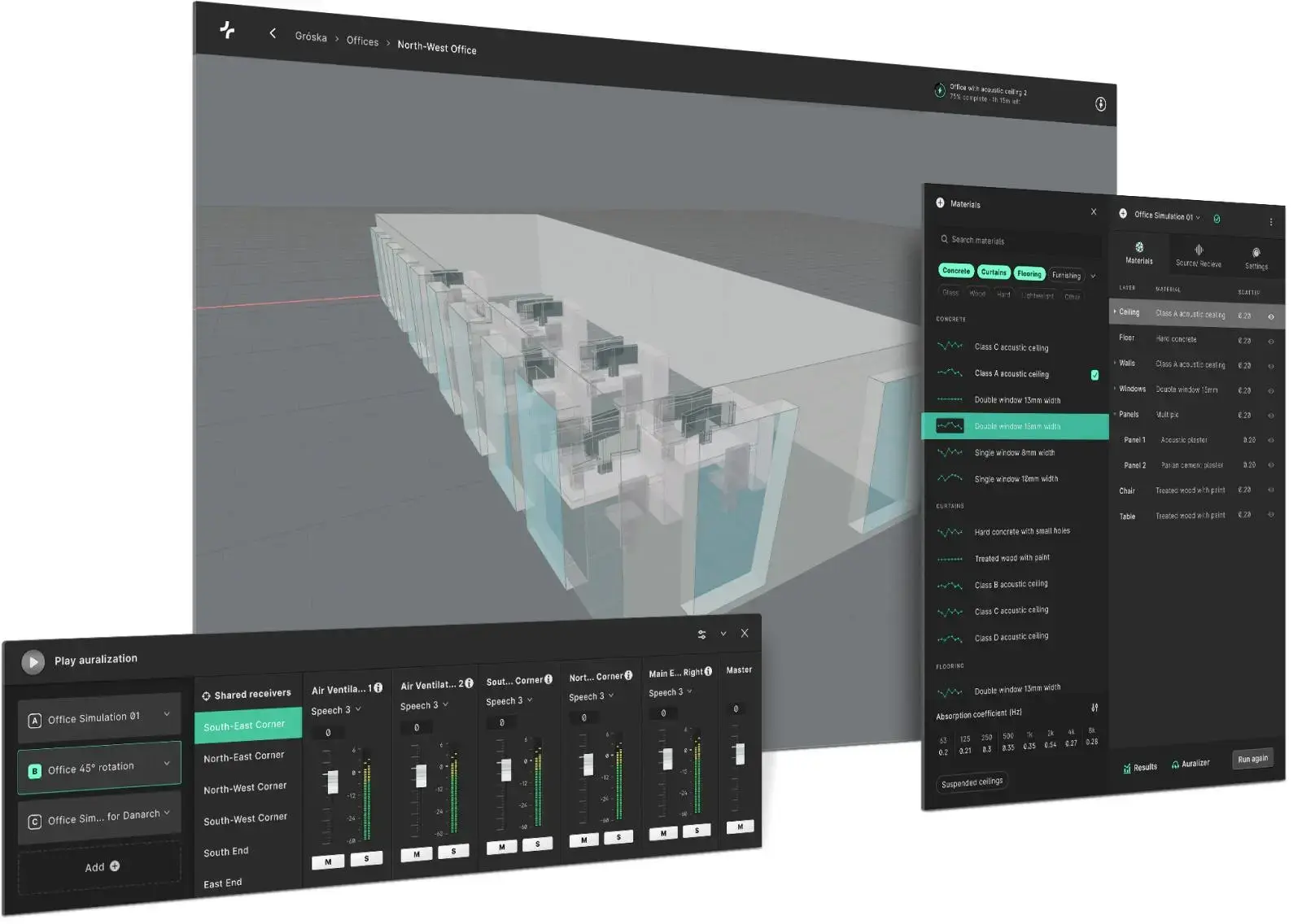

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

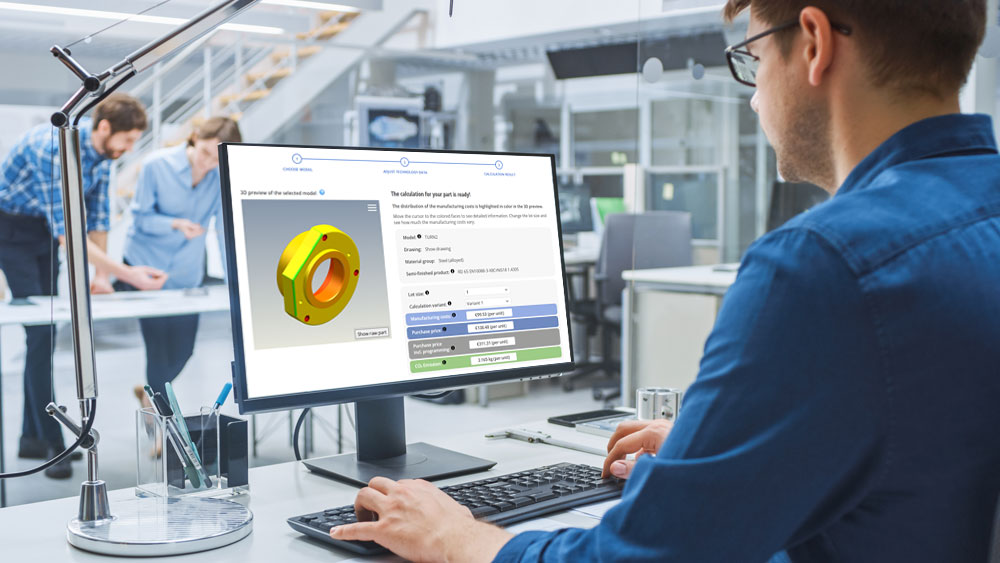

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

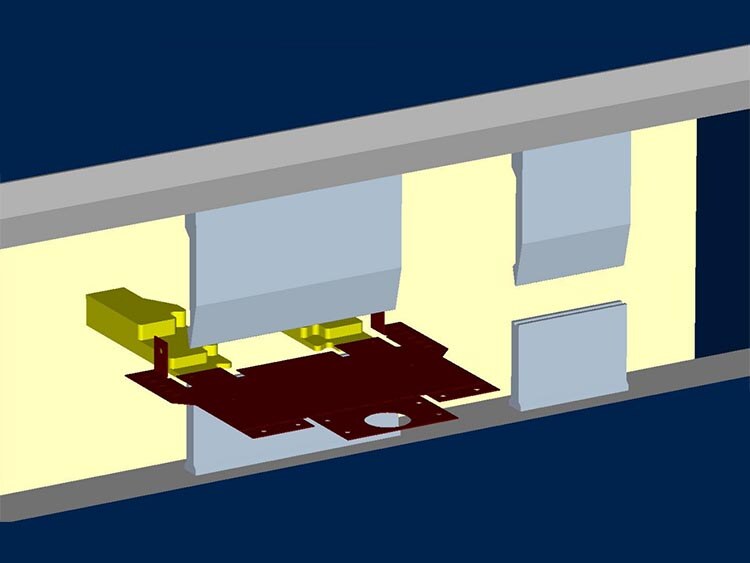

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

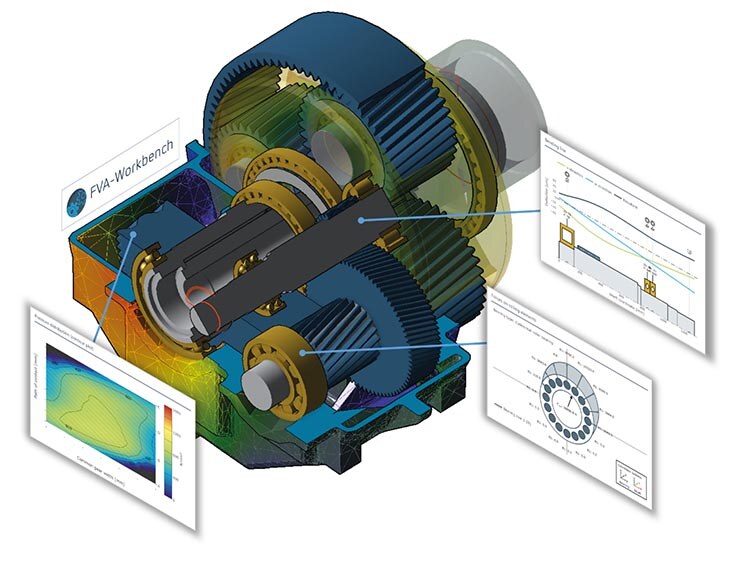

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.