LK Metrology Case Study

Market: Metrology/CMM

Summary

When LK Metrology, a leader in the Coordinate Measuring Machine (CMM) industry, sought to future-proof and develop

robustness in the code and overall offering of their CAMIO software application for programming CMMs, they returned

to Spatial’s industry-proven solutions and programs.

LK Metrology added 3D InterOp and HOOPS Visualize to round out their use of 3D ACIS Modeler and engaged in the Assessment Program. The Spatial Assessment Program enabled LK Metrology to implement the next generation of PMI/MBD technology capabilities thereby extending the lifespan of CAMIO while also benefiting from expert code review and answers to developer questions.

Working closely together with Spatial, not only strengthened our knowledge of PMI and our CAMIO software but also provided very valuable feedback to Spatial which helped to improve the Uconnect product, thereby making our product better in the end.

The Company

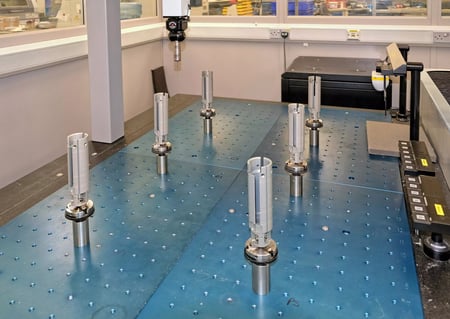

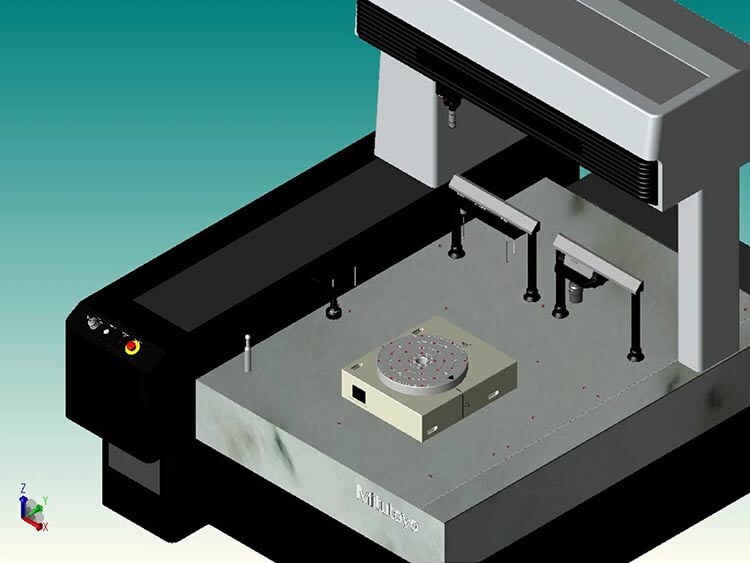

Founded in England in 1963, LK Metrology is the oldest Coordinate Measuring Machines (CMM) manufacturer in the world and creator of the CAMIO software application.

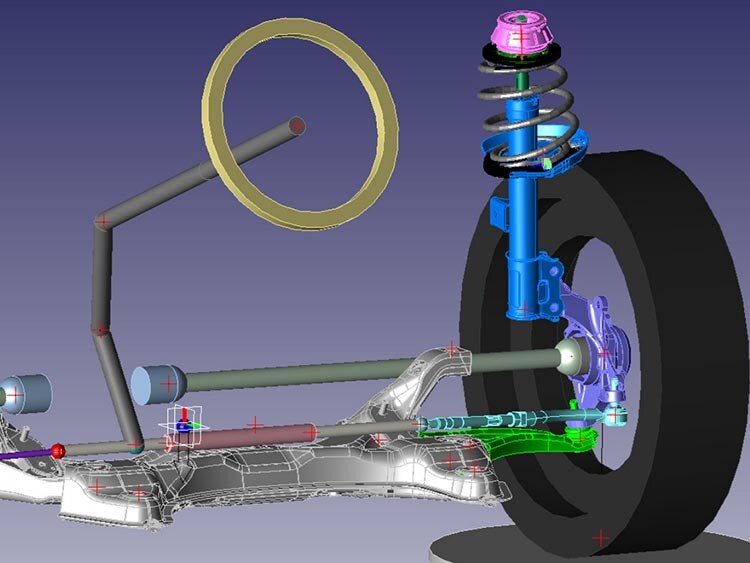

They are renowned for their innovative metrology solutions and services, and their products, including CMMs, new sensor technology such as laser scanners, surface finish, etc., and metrology software, which are used worldwide to control and improve the quality of manufactured components. Their precision technology underpins the process chain from design, development, production, and assembly through to quality assurance in global industries such as automotive, aerospace, defense, motorsport, energy, medical, and contract inspection.

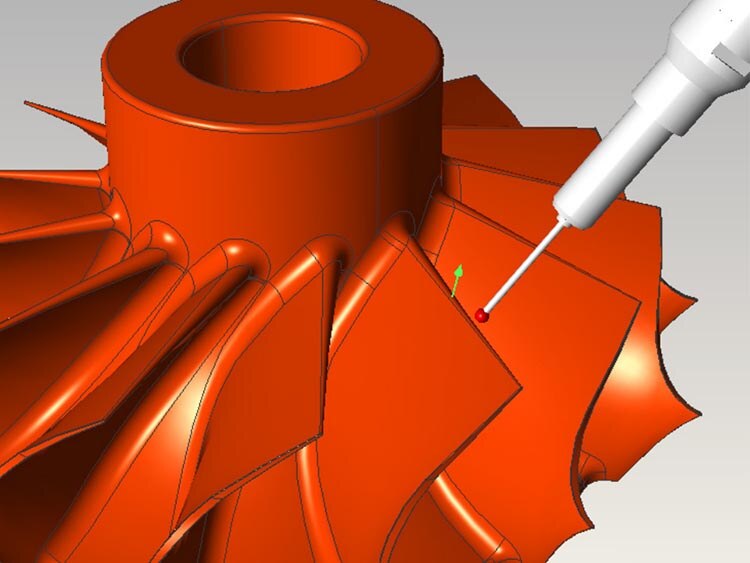

LK Metrology focuses on their products remaining as accurate as possible—a customer benefit of which they are proud. With an impressive volumetric accuracy as small as 2.1 microns, their ceramic technology CMMs set the bar high for the rest of the industry. Not only can LK Metrology customize a CMM size exactly to their customer’s specifications, but their software application, CAMIO, enables precise end-product production measurement. CAMIO has in-depth programming, analysis, and reporting capabilities for various CMM applications, enabling metrology in any industry.

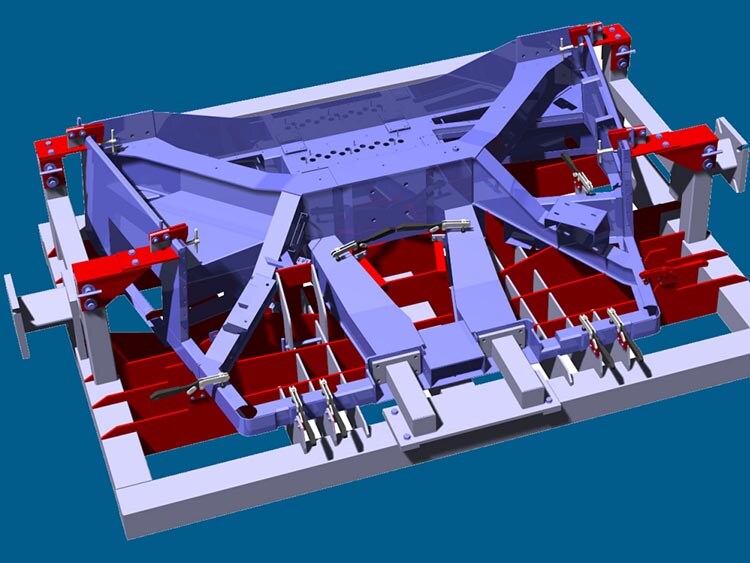

LK Metrology’s customers manufacture parts requiring inspection for dimensional accuracy and process stability. This attention to detail for customer requirements provides end users with an incomparable product built for their unique needs. Indeed, CAMIO’s robust functionality comes from specific features that LK Metrology identified as key for their customers and then built into their application.

The Challenge

A Quest to Maintain Precision for Coordinate Measuring Machines

When computer modeling first hit the market, LK Metrology decided to integrate this new technology into their metrology hardware and applications, revolutionizing their offering and the market. After more than two decades of success implementing this process, LK Metrology sought to improve their process further by refining practices and workflows. They aimed to upgrade to the best CAD engine and interoperability software while leveraging implementation expertise.

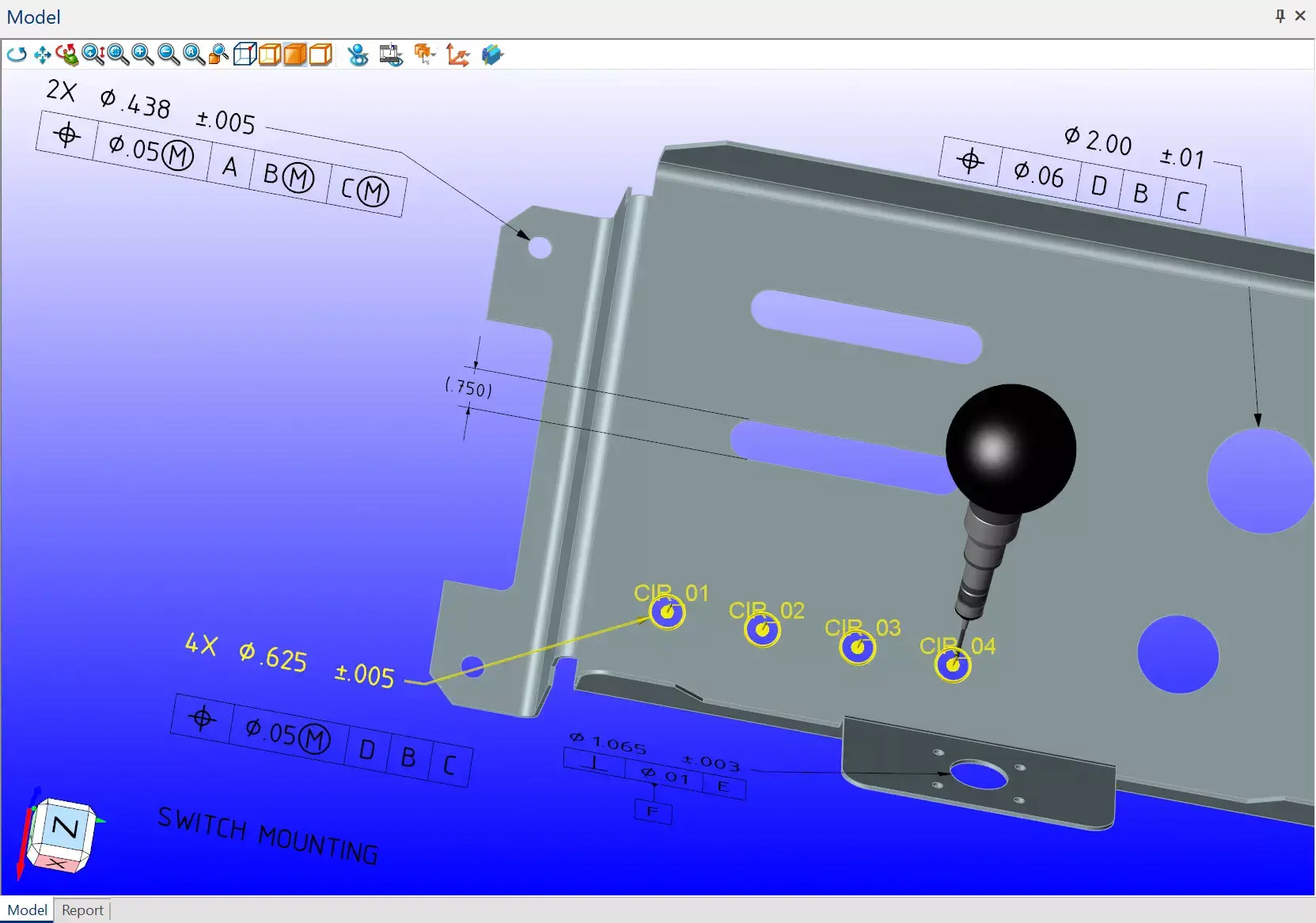

The LK Metrology team challenged themselves to expand their application and enhance end-user workflows, focusing on precise Product Manufacturing Information (PMI) and Model-Based Definition (MBD).

Their ultimate goal was to extend CAMIO functionality and make their code more robust.

The Solution

Improving Core Application Functionality Through Development Partnership

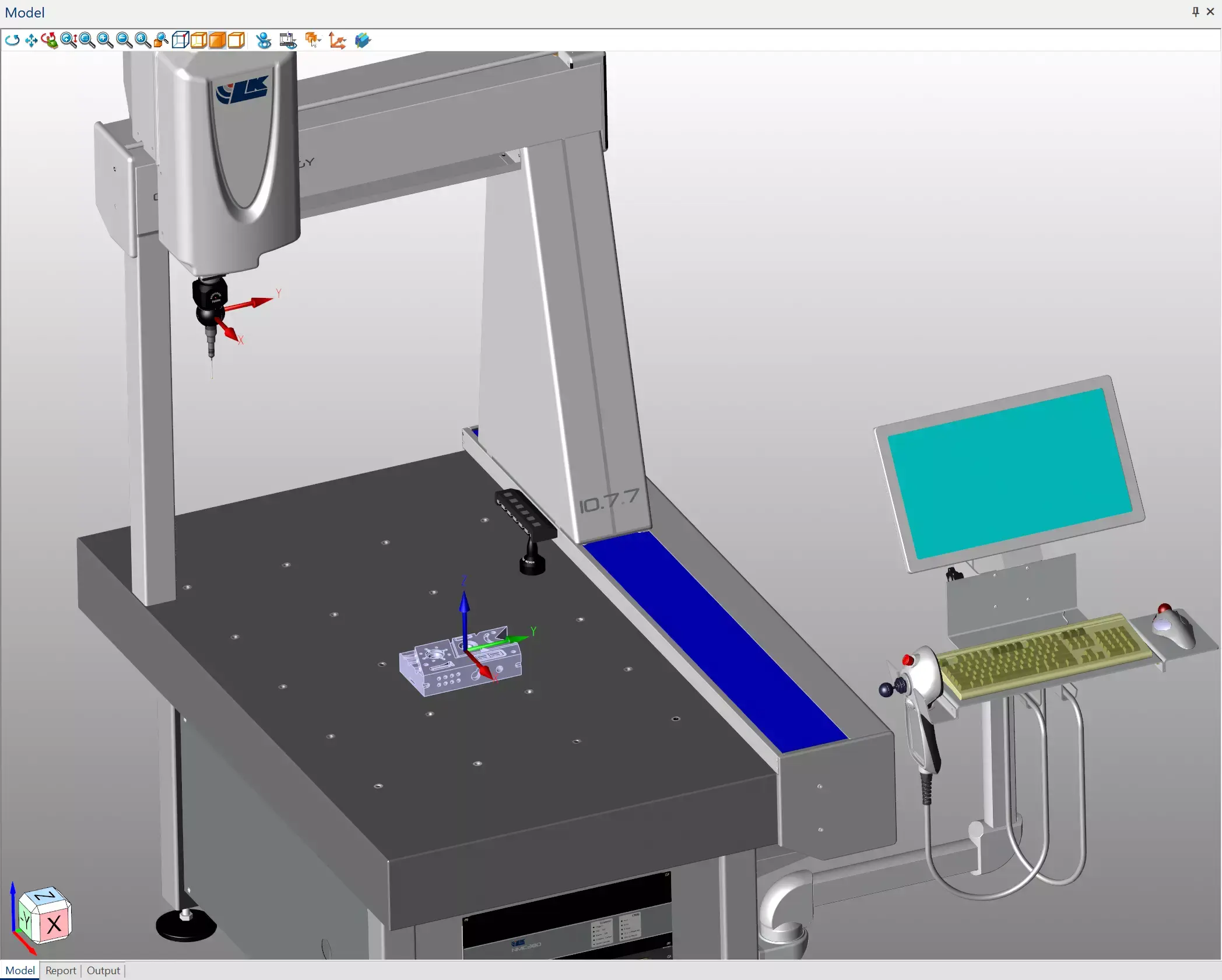

As a long-time Spatial customer, LK Metrology already had Spatial 3D components embedded in their CAMIO application and were familiar with the quality and functionality these components provide. For instance, in the 1990s, Spatial’s 3D ACIS Modeler kernel was incorporated into CAMIO, enabling the use of native CAD data to develop and validate 3D inspection programs both online and offline.

In addition to ACIS, LK Metrology licensed HOOPS Visualize and 3D InterOp to enhance the CAMIO application. 3D InterOp allows users to import, interact with, share, and export 3D data across different CMM platforms, while HOOPS Visualize improves the performance and visual display of CAMIO. With these high-performance Spatial components already integrated, LK Metrology aimed to elevate their application further by adopting the Application Lifecycle Management (ALM) framework and implementing a tailored three-phased approach through Spatial’s Assessment Program.

The ALM framework supports the management of an application’s lifecycle, from inception and development to maintenance and eventual retirement. Application developers benefit from ALM through shorter release cycles, expanded knowledge via training and workshops, and enhanced product management based on a customized assessment program. Spatial’s Assessment Program reassured LK Metrology that they were maximizing the potential of their data while providing the tools and functionality to improve end-user workflows.

A team of Spatial experts collaborated with LK Metrology to identify challenges, discuss potential solutions, and uncover new capabilities. This partnership helped LK Metrology expand their functionalities and elevate their application. Spatial demonstrated a clear understanding of the geo-specific needs of LK Metrology as an internationally diversified company.

The Results

High Quality Functionality

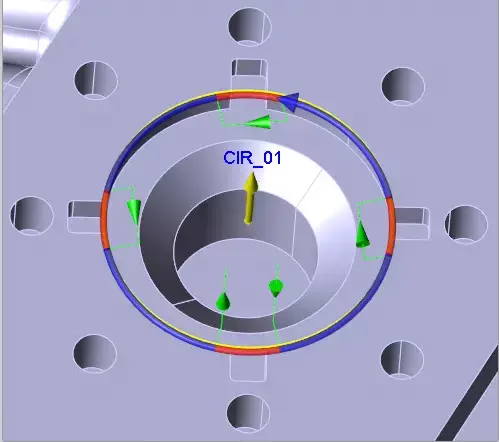

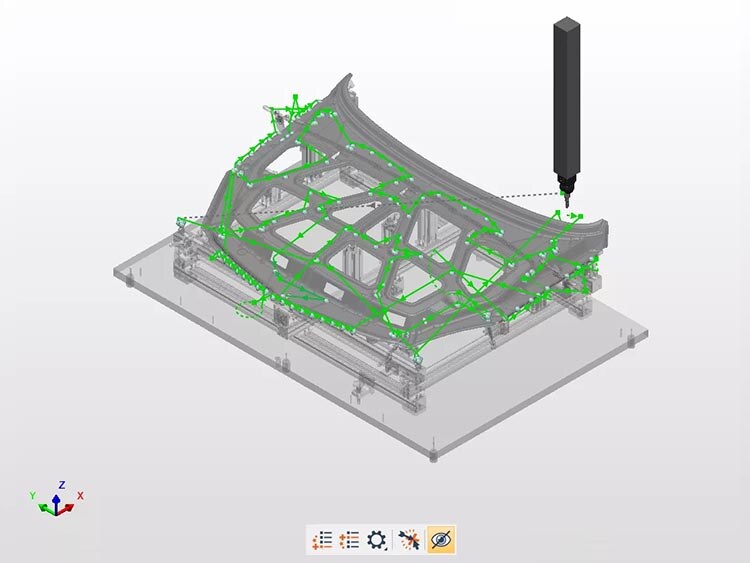

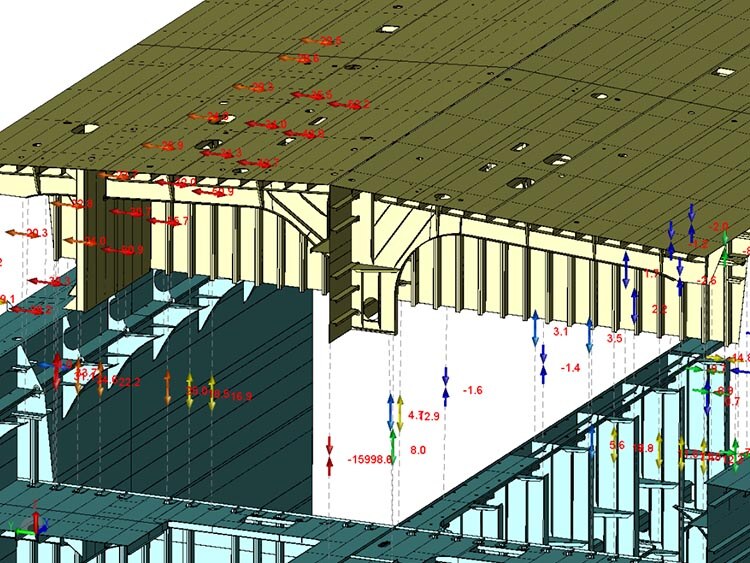

With the integration of Spatial’s 3D InterOp, CAMIO’s interoperability enables users to import, interact with, share, and export 3D data across CMM platforms and manufacturing sites. The 3D ACIS Modeler’s Geometry Validation feature automatically identifies which surfaces of the CAD model should be used for measurement, applying the appropriate touch point or scan path strategy while avoiding invalid geometry.

Advanced picking functions within the programming workflow allow users to select the correct feature type from a list of options without additional interaction. Additional features such as Auto Sensor Selection, full Probe Path simulation, and a Clearance Avoidance Box further enhance the CAMIO portfolio.

Integrating PMI and MBD for Extended Capabilities

LK Metrology knew that their implementation of Product Manufacturing Information (PMI) and Model-Based Definition (MBD) needed revamping and would need some help with extra and corner cases. As a result, Spatial helped integrate PMI and MBD reading and processing technology within CAMIO, a big part of extending the application’s capabilities. Spatial then consulted with LK to review their implementation to ensure it was secure, efficient, and robust.

Thus, users can now quickly identify the links between graphical PMI and semantic PMI. They then can add the features, datum features, and tolerances into the existing teach path workflows that logically order the items and apply the measurement strategies and clearance moves. This process creates large sections of DMIS code with minimal user input.

Key Insights

Looking at the future of the metrology market, the milestones are clear: precision and accuracy of code remain critical, alongside supporting software application developers with an industry-proven process from start to finish.

As Model-Based Definition (MBD) and Product Manufacturing Information (PMI) gain traction, customers are increasingly likely to expect these features as standard in software.

LK Metrology, already exceeding industry standards with their precision solutions, sought to future-proof their CAMIO application by developing robustness in their code and expanding capabilities. They trusted Spatial for a comprehensive solution and explored new possibilities with their file formats, benefiting from Spatial’s improved quality and capabilities throughout the process. By partnering with experts like Spatial, LK Metrology continues to lead the CMM industry, setting an example of excellence and demonstrating what metrology software can achieve. Their customers value the reliability, power, and advanced capabilities of Spatial’s proven, world-class components.

Download the Full Case Study

Want to see a more detailed breakdown of how LK Metrology utilized Spatial’s powerful components in their application? Download the full case study by clicking below.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

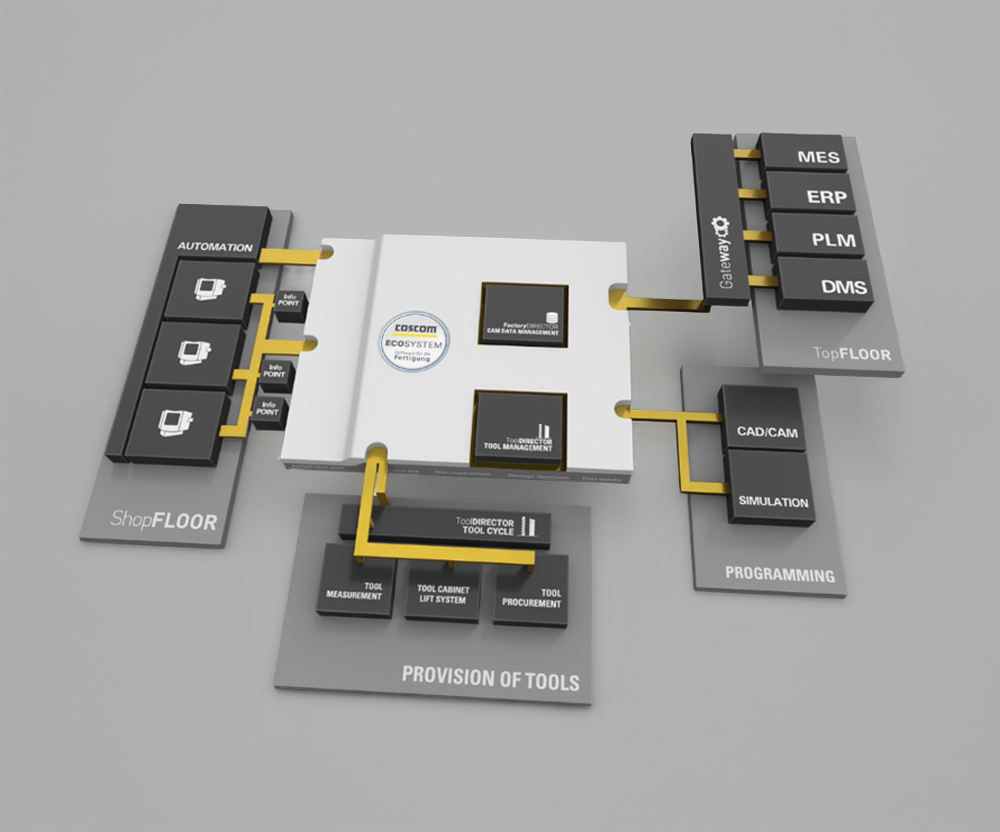

COSCOM optimized CNC Digital Twins with Intelligent CAD Data Reduction

COSCOM needed an efficient solution to manage massive CAD data volumes in their digital twin application while maintaining precision for collision detection and machine simulation in CNC machining processes.

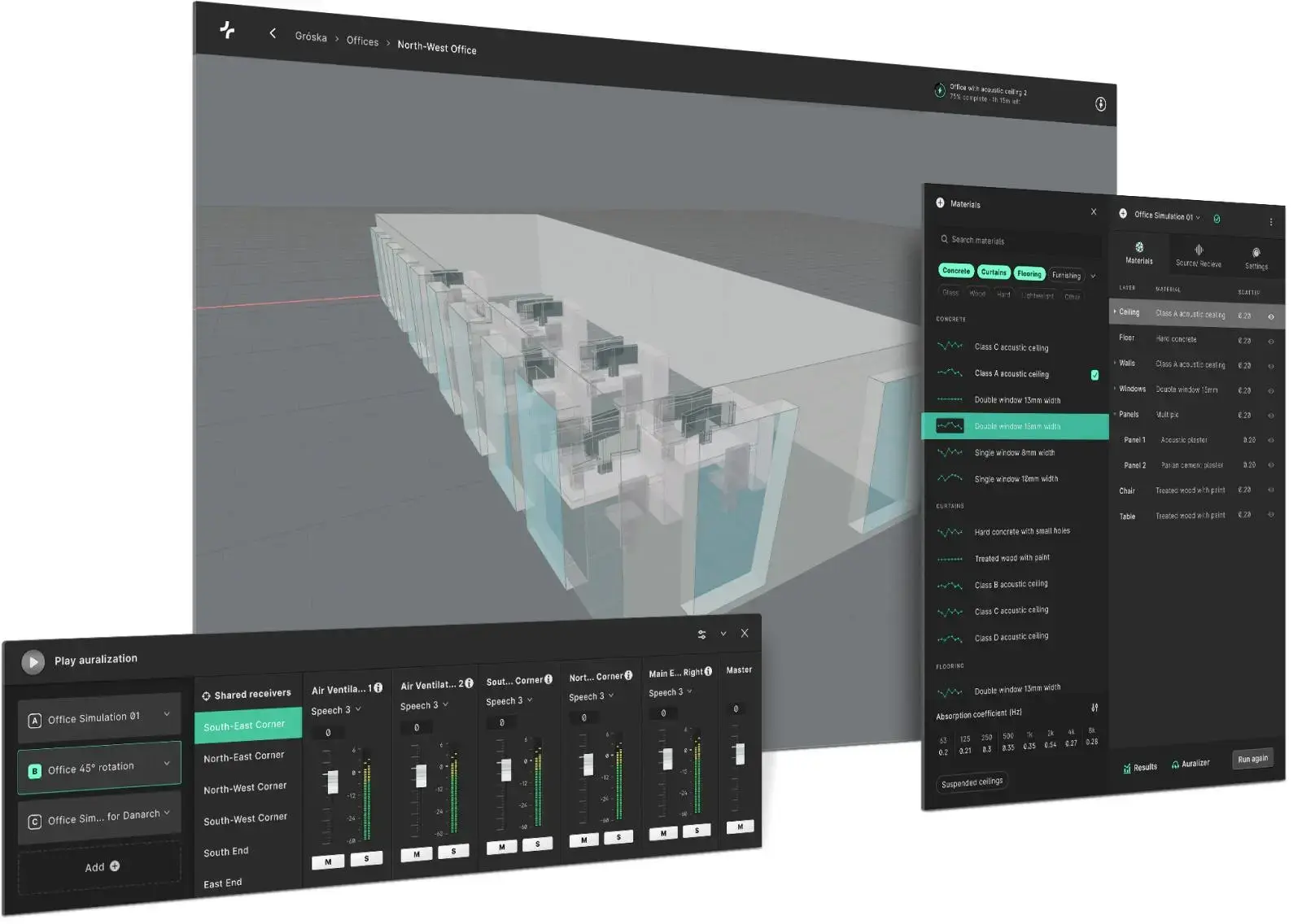

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

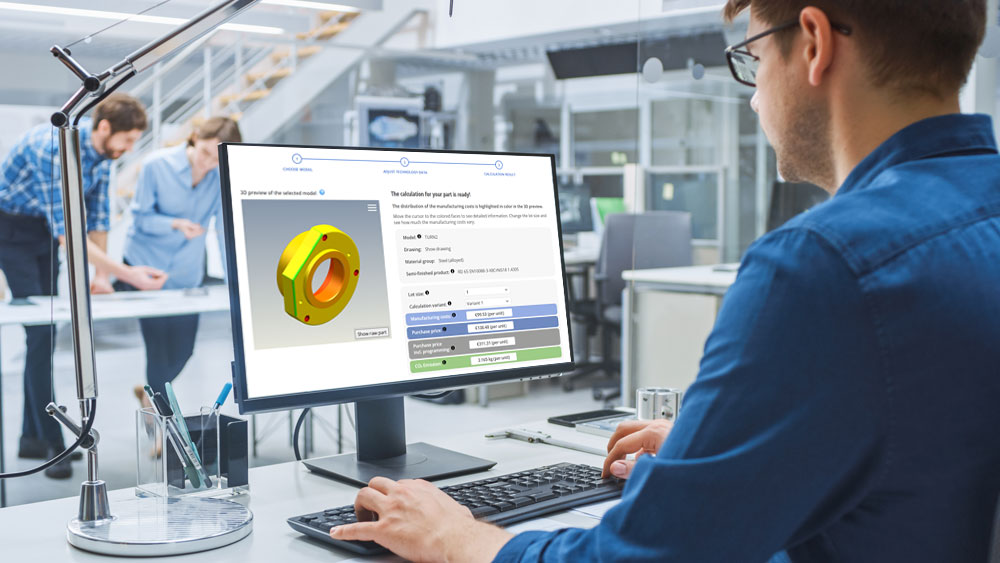

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

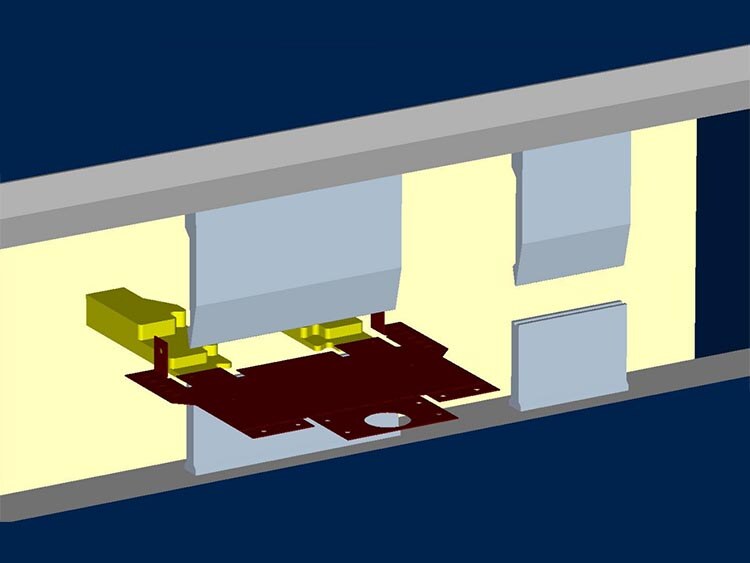

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

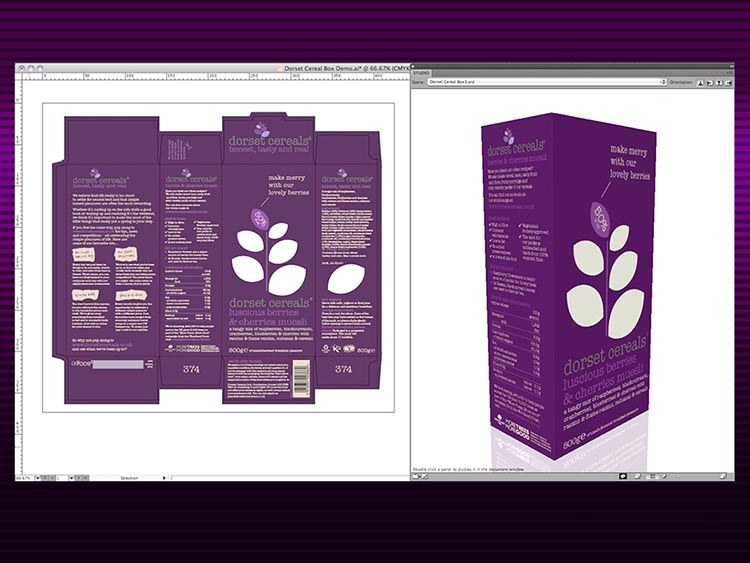

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

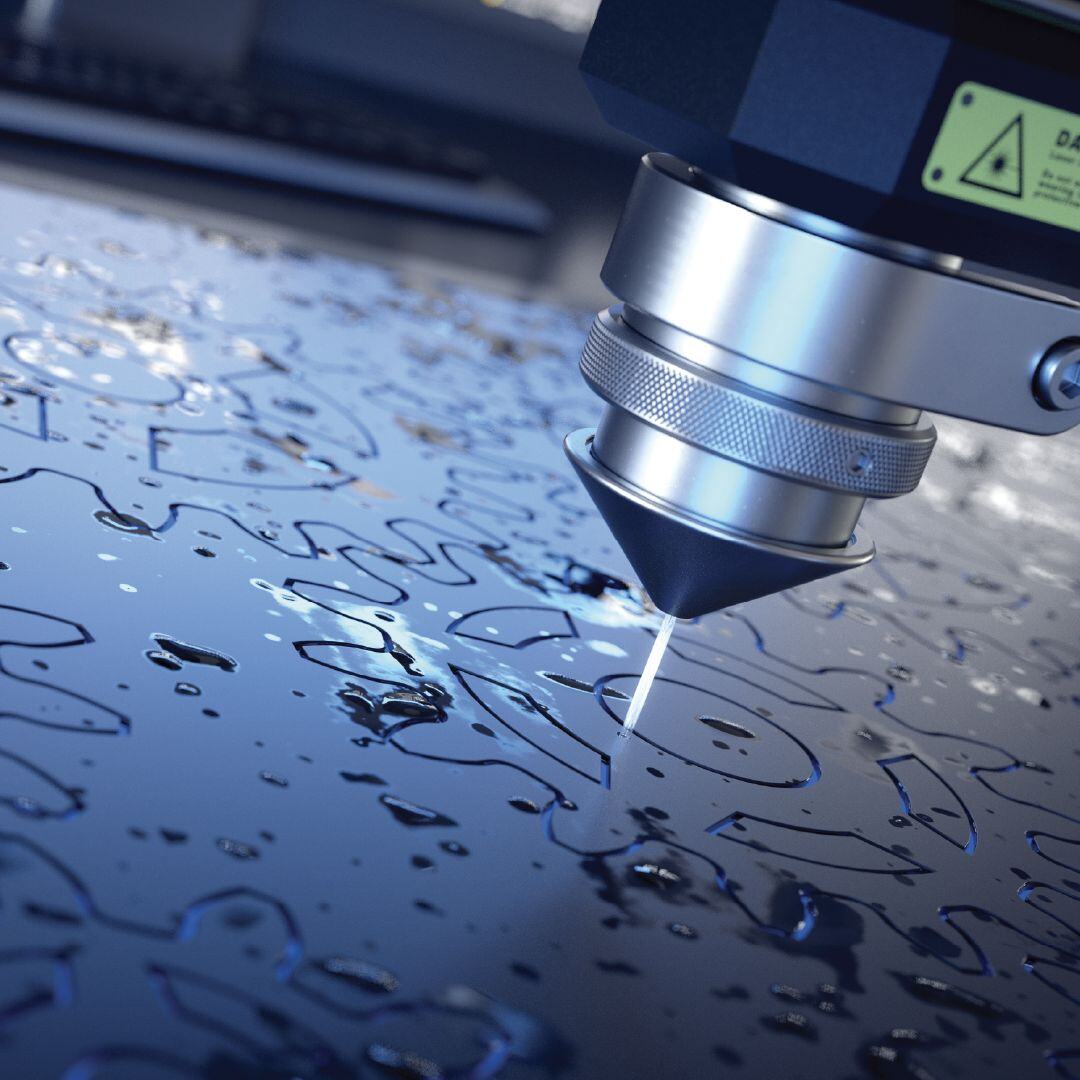

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

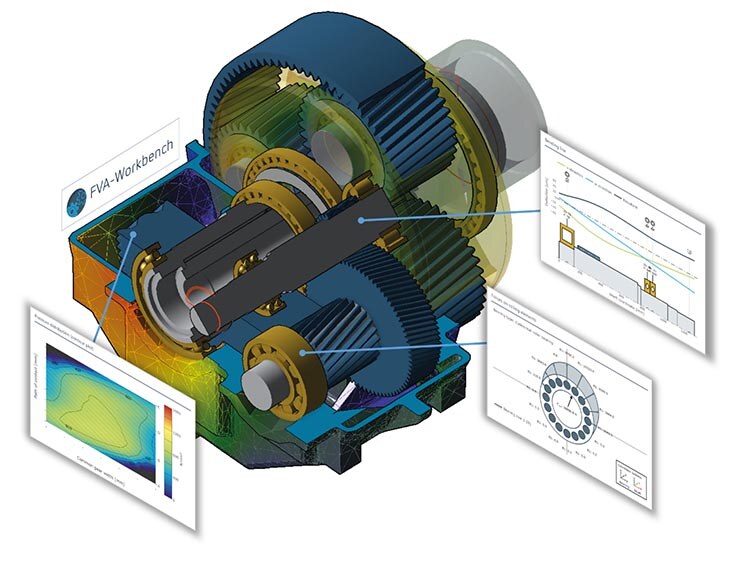

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

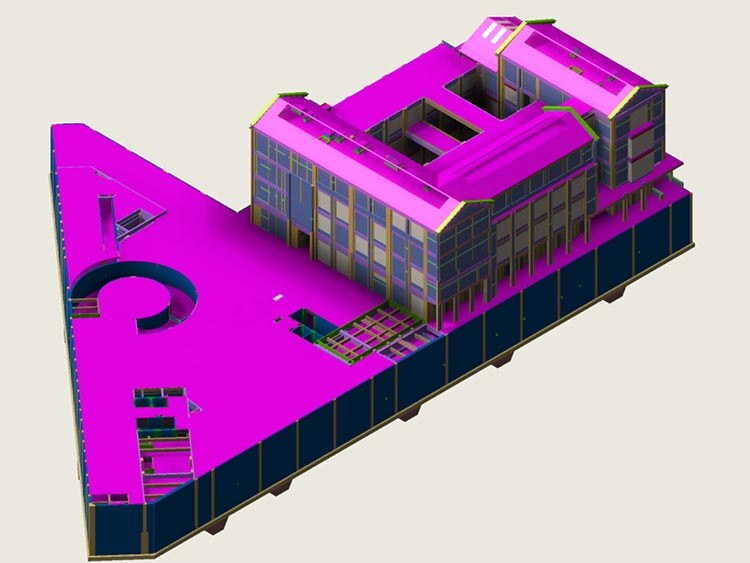

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.