TraceParts Case Study

Market: CAD

Summary

Proven Software Development Kits from Spatial offer a browser-based 3D modeling and cloud CAD solution for high-quality rendering of CAD parts for engineering, industrial equipment, and machine design.

We trust Spatial’s technology and appreciate the unwavering support from their technical and R&D teams, ensuring seamless integration into our workflows and business processes.

The Company

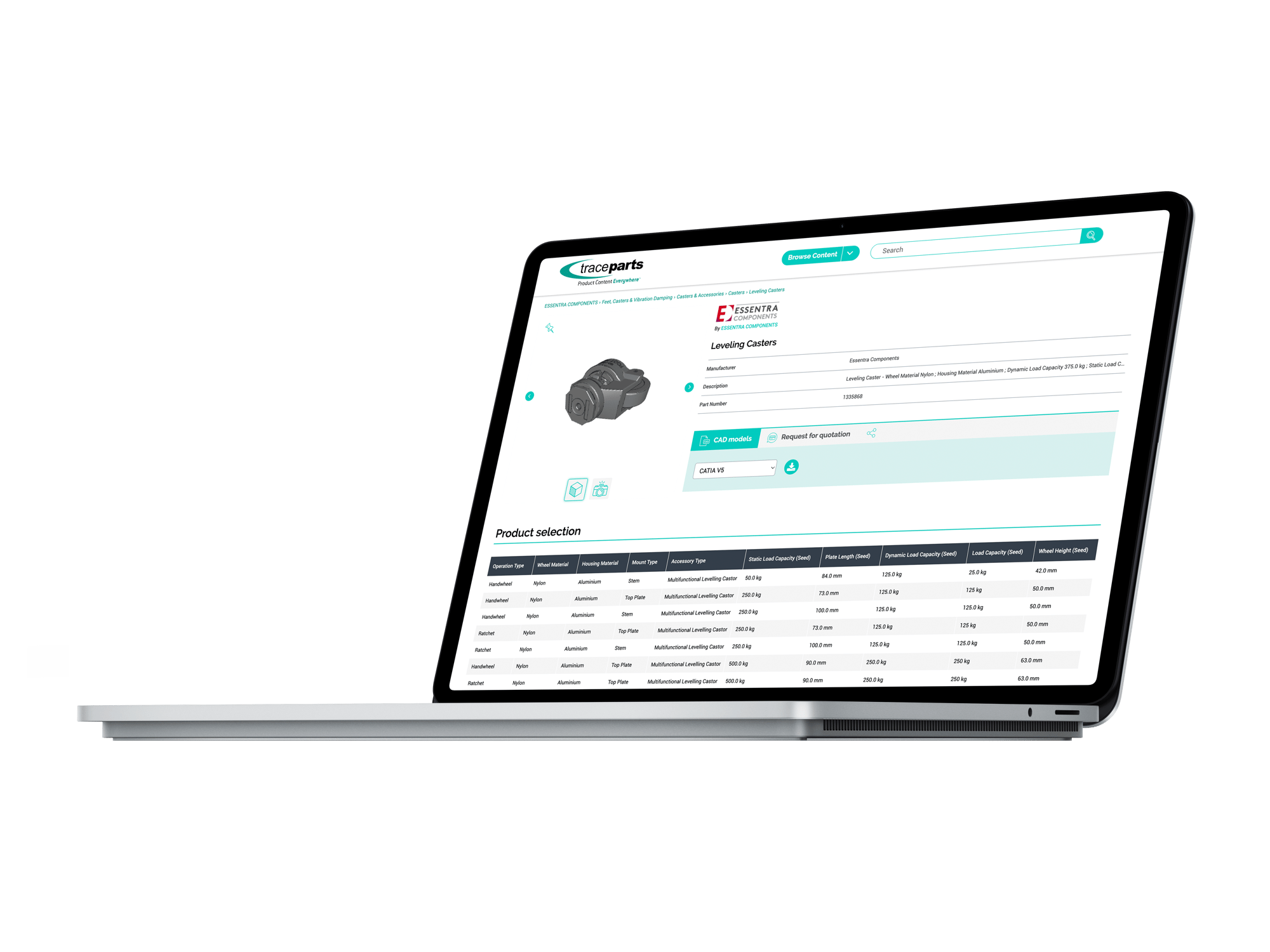

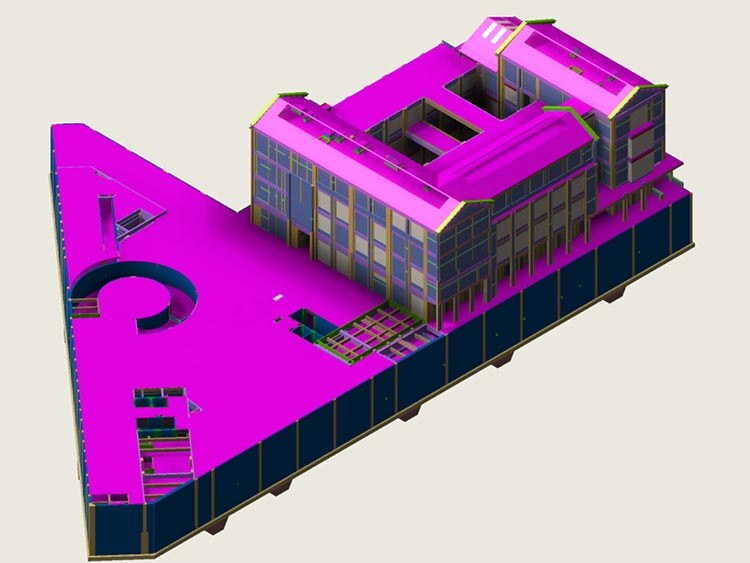

Founded in 2001, TraceParts is a leading supplier of CAD content for engineering, industrial equipment, and machine design worldwide. The company has over 5.7 million registered members from 1.3 million companies actively sourcing product information and technical data from over 195 countries. As of early 2025, TraceParts has over 2,100 product catalogs of industrial components and over 238 million downloads. TraceParts is a CAD content platform offering billions of CAD models from industrial components in 60+ 2D and 3D formats. The company provides highly targeted marketing exposure to customers of all sizes and industries via powerful cloud-based API and SaaS applications such as CAD part libraries, product catalogs, and configurators.

TraceParts offers a unique modeling technology that directly re-uses existing product CAD models and turns them into virtually any format while keeping the customer’s intellectual property safe. The customer simply uploads their 3D files and product data and TraceParts does the rest. TraceParts can also parametrically model customer products from scratch using their product datasheets and specifications. The result is true-to-scale CAD models in 60+ different output native and neutral formats, and design-related rich product information.

Since 2010, certain TraceParts’ output CAD formats have used Spatial’s 3D ACIS modeling kernel and 3D InterOp Software Development Kits. 3D ACIS Modeler delivers the technological capabilities needed to create high-quality applications, supporting various industrial modeling approaches, including direct and history-based modeling. 3D InterOp enables TraceParts’ application to work seamlessly with an extensive breadth of CAD formats.

The Challenge

Providing a crowd-pleasing and high-functioning online 3D viewer

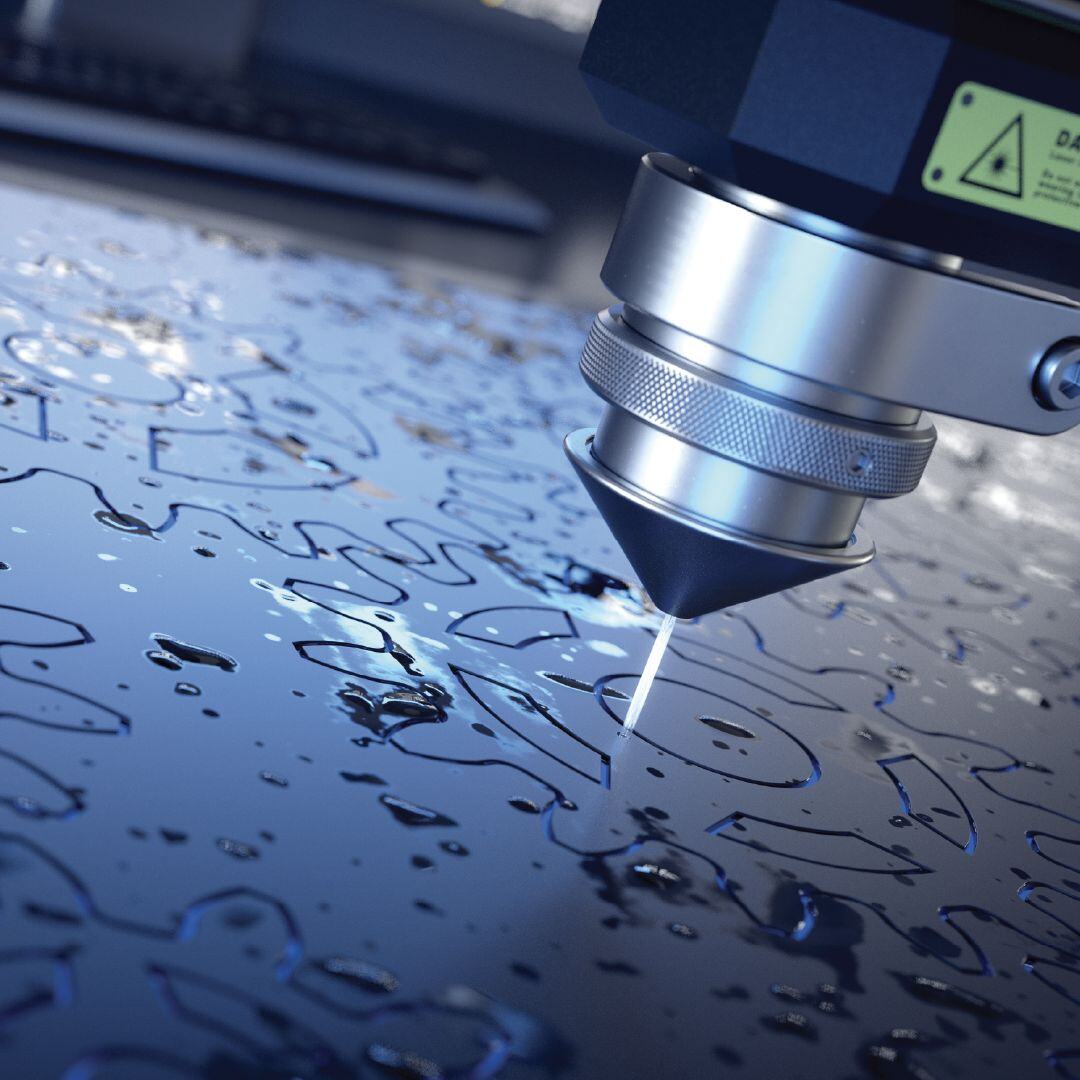

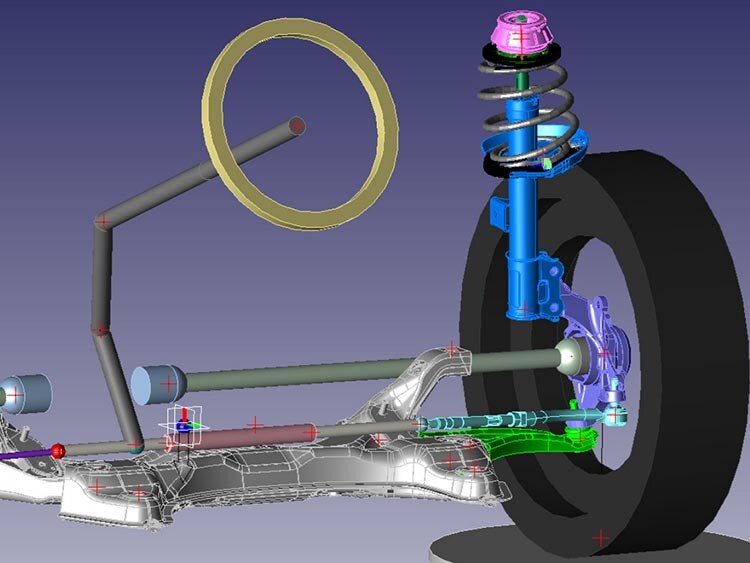

Machine design optimization has never been so critical in today’s fast-moving market. Manufacturing industries want to reduce their time to market and industrial designers and engineers continually tackle design challenges. TraceParts aims to save design time with their innovative CAD content platform.

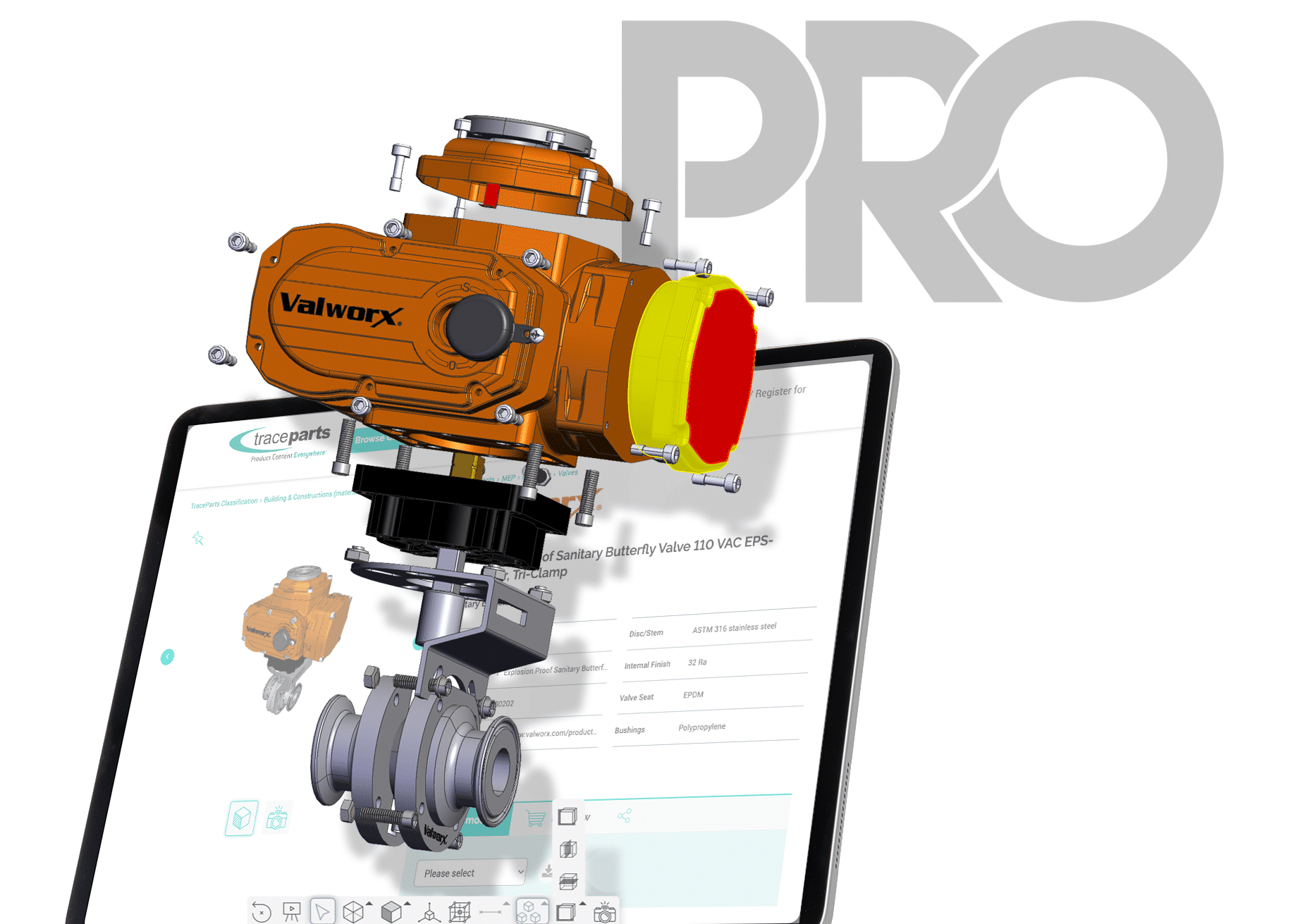

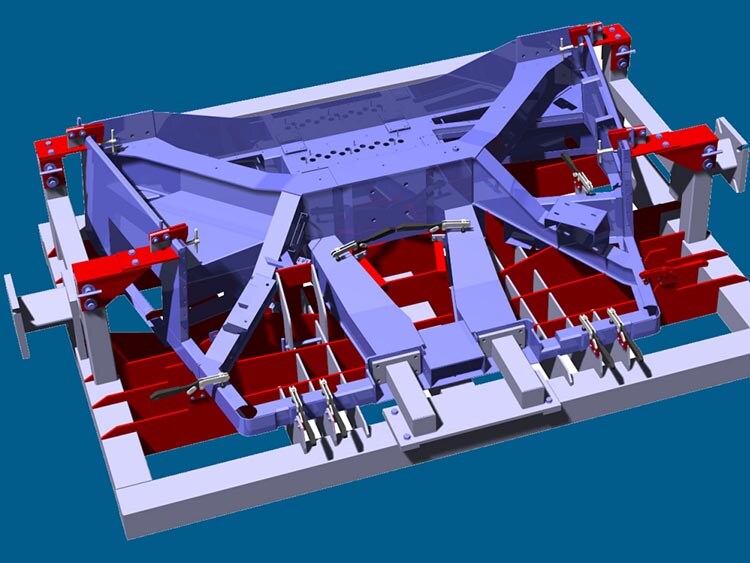

As part of the online ordering process, customers can preview their selected part in TraceParts 3D Viewer Pro. The 3D preview function needed to perform seamlessly for the customer and allow them to manipulate the part on screen. They required a robust browser-based 3D modeling and cloud CAD solution for high-quality rendering.

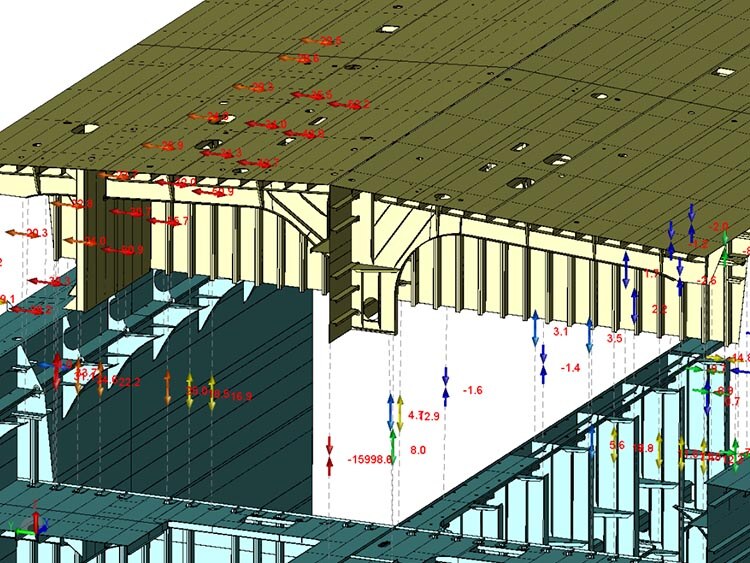

Additionally, TraceParts wanted to bring more advanced CAD features into their online viewer such as interactive measurements, multiple cutting planes, and exploded views on assemblies. This allows their customers to go beyond visualization and offer their promise of gaining productivity by working faster and better.

The Solution

3D web visualization through seamless integration and high-quality rendering

TraceParts’ 15-year relationship with Spatial had already formed the foundation for a successful partnership. The company’s use of 3D ACIS Modeler and 3D InterOp has proven the high-quality of Spatial’s Software Development Kits (SDKs) working within TraceParts’ application. As TraceParts faced new challenges, it became the right time to bring the powerful 3D web visualization component, HOOPS Communicator, on board.

Critical to the TraceParts team’s decision was that HOOPS Communicator can be seamlessly integrated throughout the rest of the Spatial data processing workflow. The integration process involved generating HOOPS models (.scs files) using a HOOPS bridge provided by the Spatial team. The bridge can be utilized in two ways: using only the ACIS kernel to generate .scs files from ACIS entities in memory, or using 3D InterOp to convert an existing .sat or .step file to a .cs file or any other CAD format.

Following that process, based on a specific option in the definition of each customer contract, TraceParts can instantly replace the legacy TraceParts basic viewer with the new TraceParts 3D Viewer Pro directly on the customer product catalog pages. HOOPS Communicator is also offered as a contract option to TraceParts customers when they want to embed interactive 3D viewing on their product pages seamlessly.

The full integration of the HOOPS Communicator took only two months, and the Spatial Technical Account Managers worked alongside TraceParts’ developers to provide proactive support along the way.

Key Insights

SDKs complement each other to provide comprehensive solution

When the new TraceParts 3D Viewer Pro with HOOPS Communicator was launched, it bridged a gap in the company’s product offerings.

The seamless integration of the HOOPS SDK with the existing 3D ACIS Modeler and 3D InterOp saved TraceParts implementation time, and had the added bonus of a trusted partner and known support. Now, the TraceParts 3D Viewer Pro has expanded the capabilities of the CAD content company, enabling customers to access thousands of 3D industrial models for engineers.

Download the Full Case Study

Want to see a more detailed breakdown of how TraceParts utilized Spatial’s powerful components in their application? Download the full case study by clicking below.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

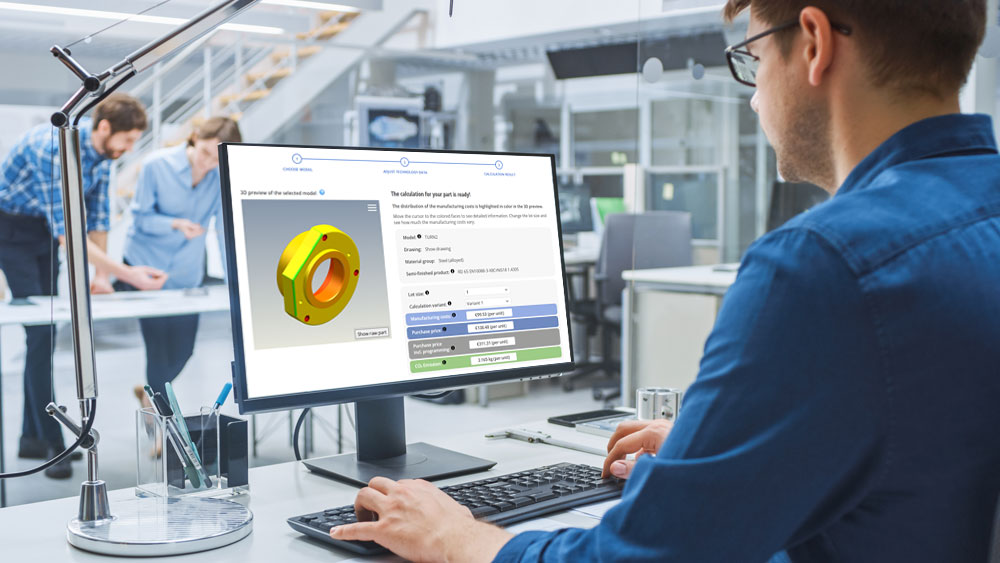

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.

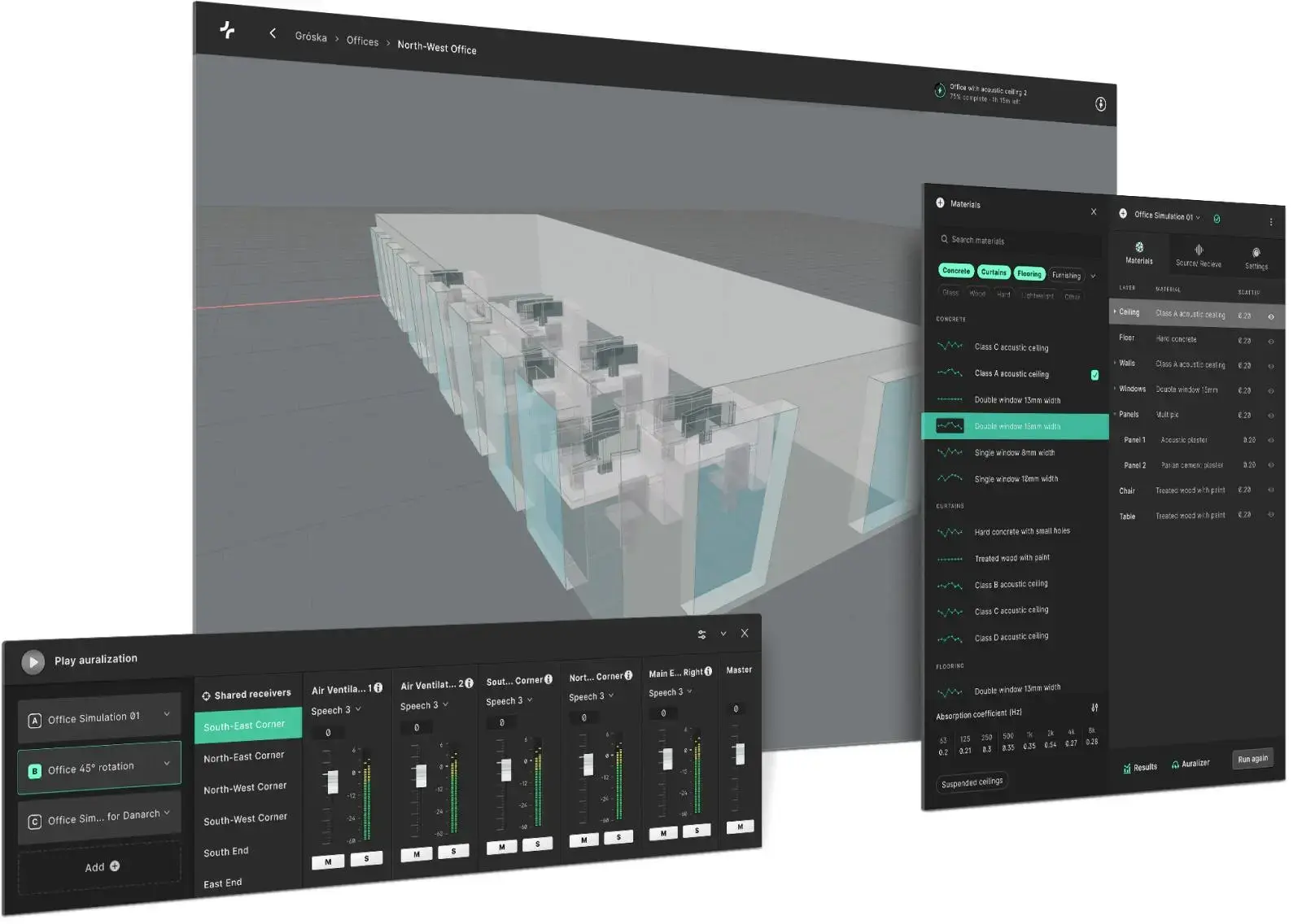

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

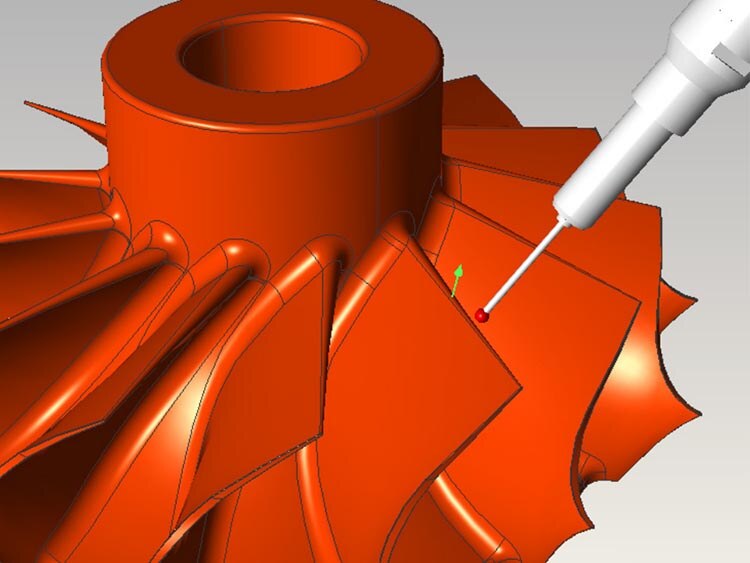

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

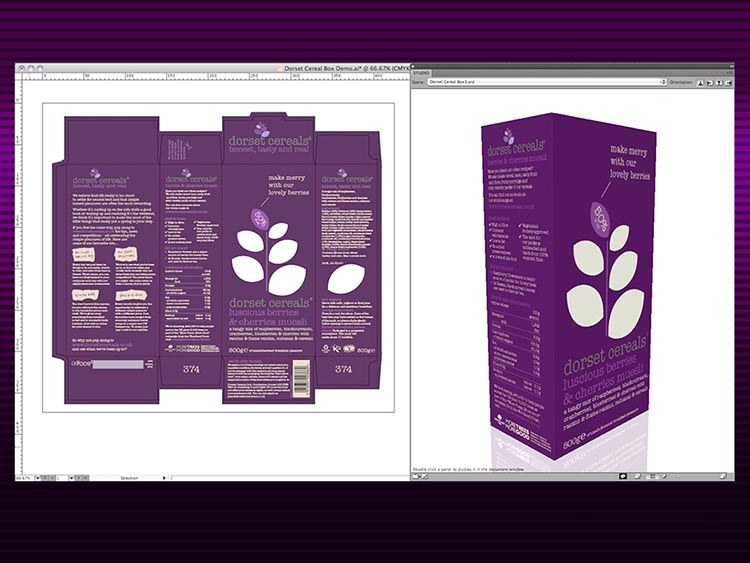

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

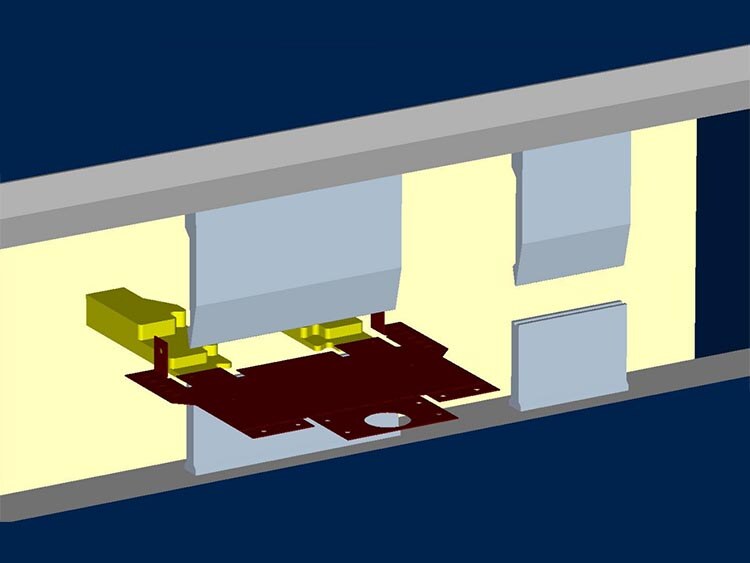

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

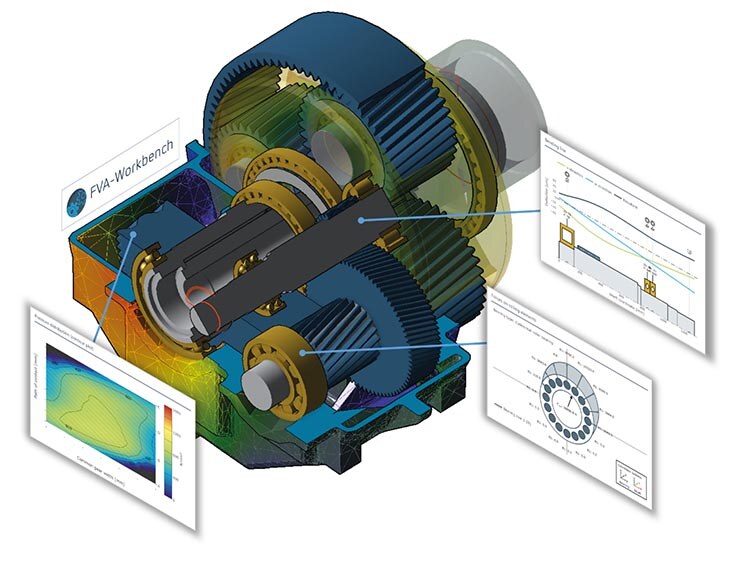

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

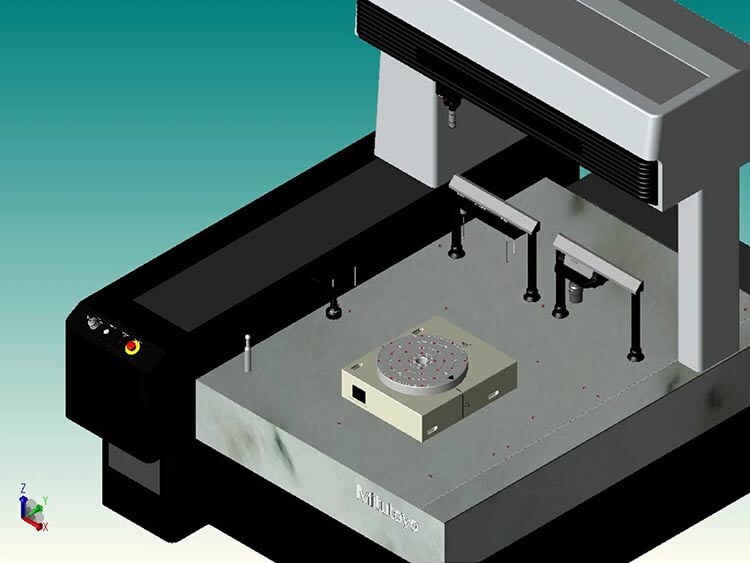

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.

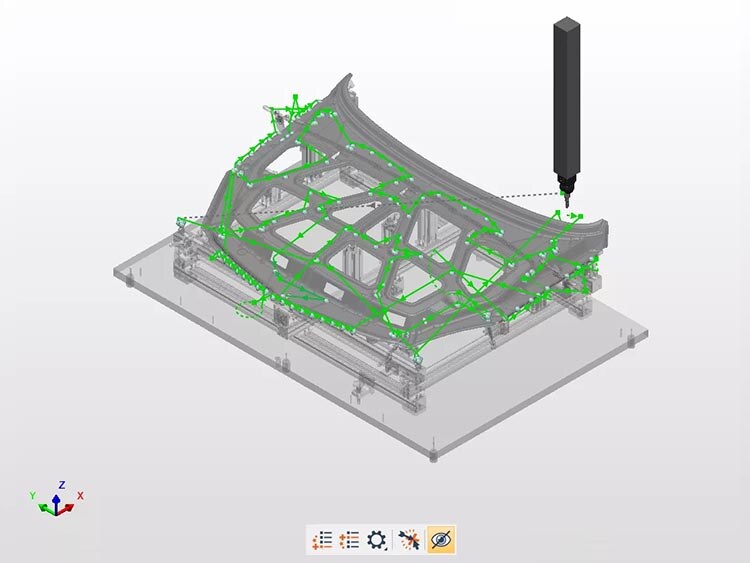

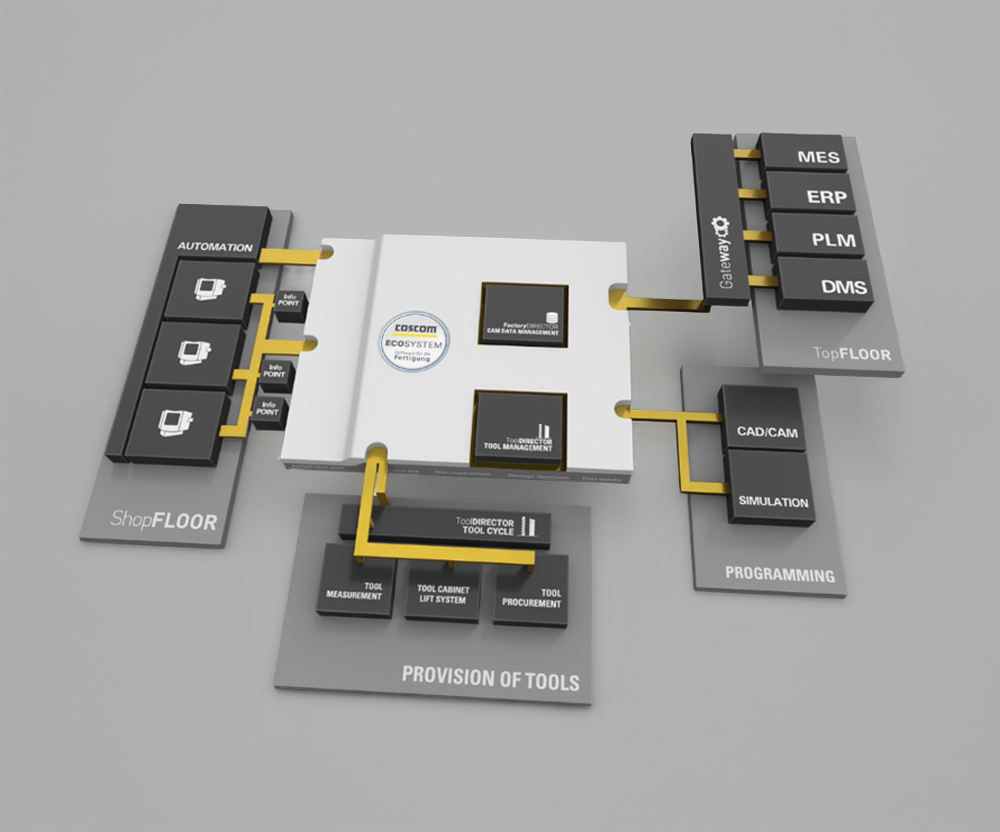

COSCOM optimized CNC Digital Twins with Intelligent CAD Data Reduction

COSCOM needed an efficient solution to manage massive CAD data volumes in their digital twin application while maintaining precision for collision detection and machine simulation in CNC machining processes.