3D SDKs for Manufacturing Software Providers

Are you looking to enable automation in your manufacturing application? Would you benefit from seamlessly and automatically merging previous design edits into one final model? Incorporating Spatial Software Development Kits (SDKs) for 3D modeling, CAD translation, and visualization allows you to streamline manufacturing processes and deliver highly competitive, integrated solutions.

Key Challenges in Software

Development for Manufacturing

Data

Integration

Ensuring smooth data exchange between CAD, CAM, and CAE applications.

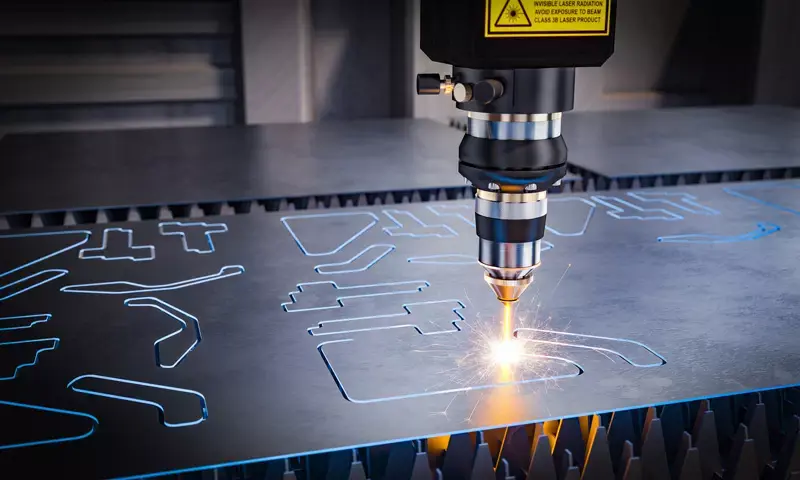

Process

Optimization

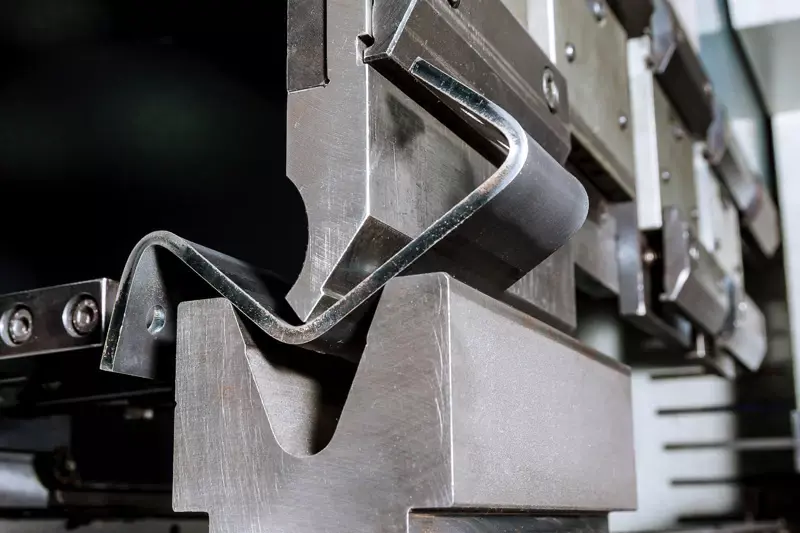

Streamlining complex processes like waterjet cutting and CNC milling.

Faster

Development

Shortening time to market by leveraging robust 3D modeling SDKs.

Incomplete

CAD Updates

Building tools to handle missing features and enable seamless CAD version updates.

Addressing Your Challenges

With Our SDKs

Data Interoperability for High-Quality CAD Translation

- Access high-quality CAD data translation with 3D InterOp, enabling precise imports of product structure, graphics, and geometry while preserving design intent and PMI.

- Optimize 3D data with Spatial’s Data Prep, using advanced algorithms to reduce model complexity and size through filtering and compression.

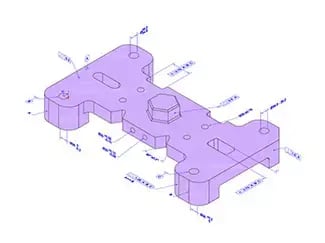

3D Modeling Features for Machining Operations

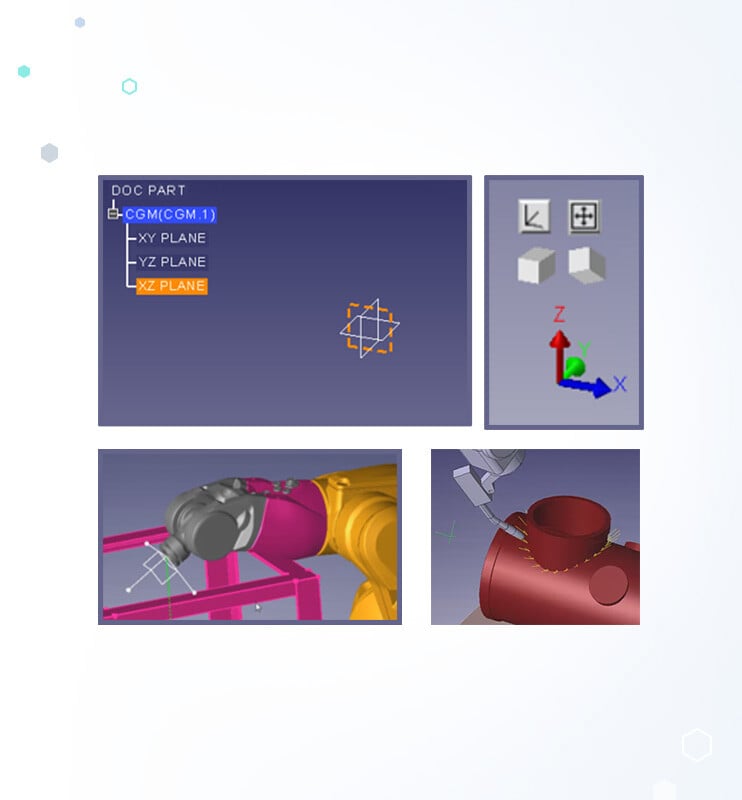

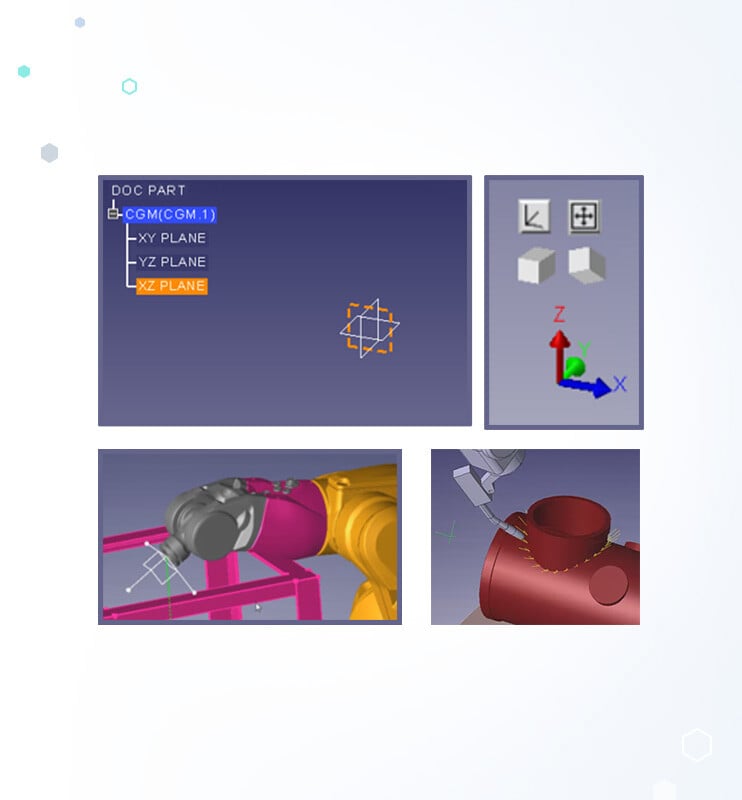

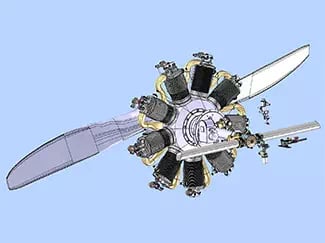

- 3D ACIS Modeler is the legacy modeler used by millions of users for over 35 years. CGM Modeler, Spatial’s next gen modeler, has advanced feature recognition and defeaturing that supports several manufacturing features for machining operations. Robust capabilities within these modeling kernels allow developers to deliver solutions that offer optimal accuracy, flexibility and usability in an integrated solution.

Proven 3D Application Development Framework

- AGM is a versatile and comprehensive 3D application development framework. It delivers tools for creating robust 3D applications, integrates seamlessly with all other Spatial SDKs and offers fast collision checks providing accurate and reliable simulations of manufacturing processes.

Efficient Collaboration

- Effective integration and communication between the top floor and the shop floor are essential. Spatial solutions are key to closing this gap. CGM Modeler and 3D InterOp support CAM engineers by enabling the import of CAD models from various systems into your application. These tools facilitate the analysis and optimization of models through quick and precise geometry edits and the generation of tool path calculations.

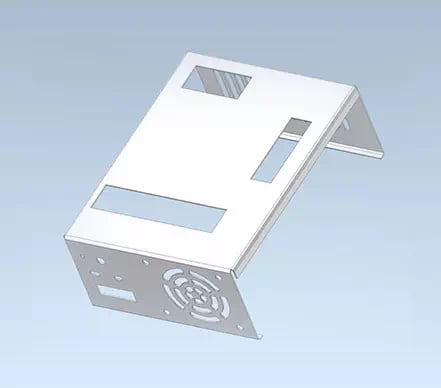

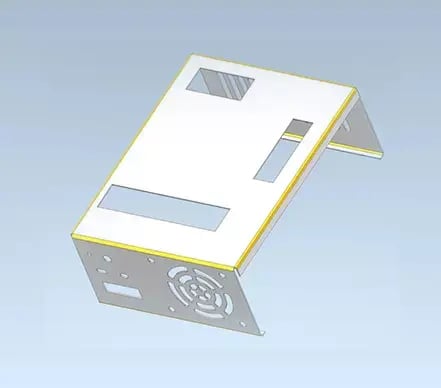

Specific Workflows for

Manufacturing and Fabrication Software

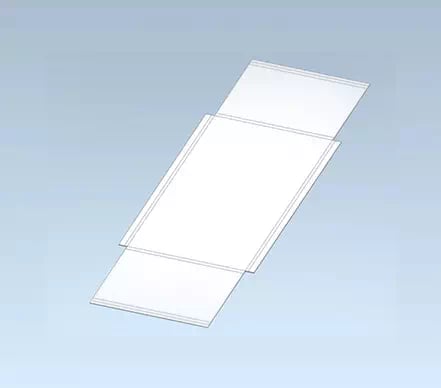

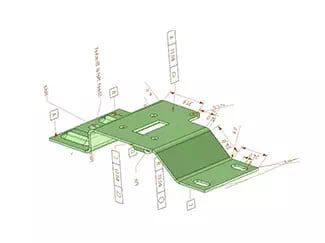

when CGM Modeler and 3D InterOp are on the job: import part, automatically detect bends,

unfold bend, remove holes and cut-outs and determine size of sheet metal blank.

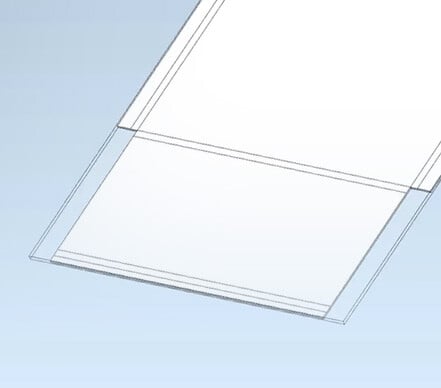

1. Import Sheet-Metal Part

- Part and assembly import

- Selective B-Rep import

- Semantic and graphical PMI

- CAD associativity

2. Automatically Detect Bends

- Detect cylindrical bends

- Control the bend-detection process with options

- Bend objects are created with geometric properties

4. Remove Holes and Cut-Outs

- Holes and cut-outs are detected by feature detection functionality in CGM Modeler

5. Determine Size of Sheet-Metal Blank

- A bounding box is created from the external perimeter of the unfolded and de-featured housing

Features Designed for Manufacturing

and Fabrication Workflows

Going beyond more general third-party products, custom solutions provide greater flexibility,

more control over product direction and focus on key differentiators including ease of use,

streamlining operations and cost savings.

Large CAD Assembly Import

Seamless Large Assembly Integration

3D InterOp offers advanced support for importing large CAD assemblies, ensuring smooth and efficient handling of complex designs. This capability is crucial for maintaining fidelity and performance, enabling users to work with detailed assemblies without compromising on speed or accuracy.

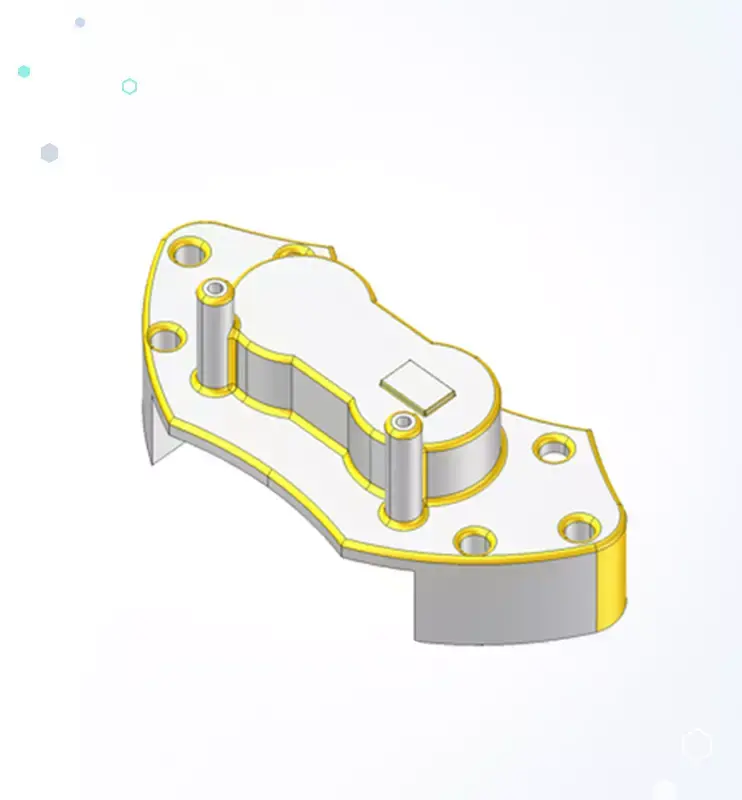

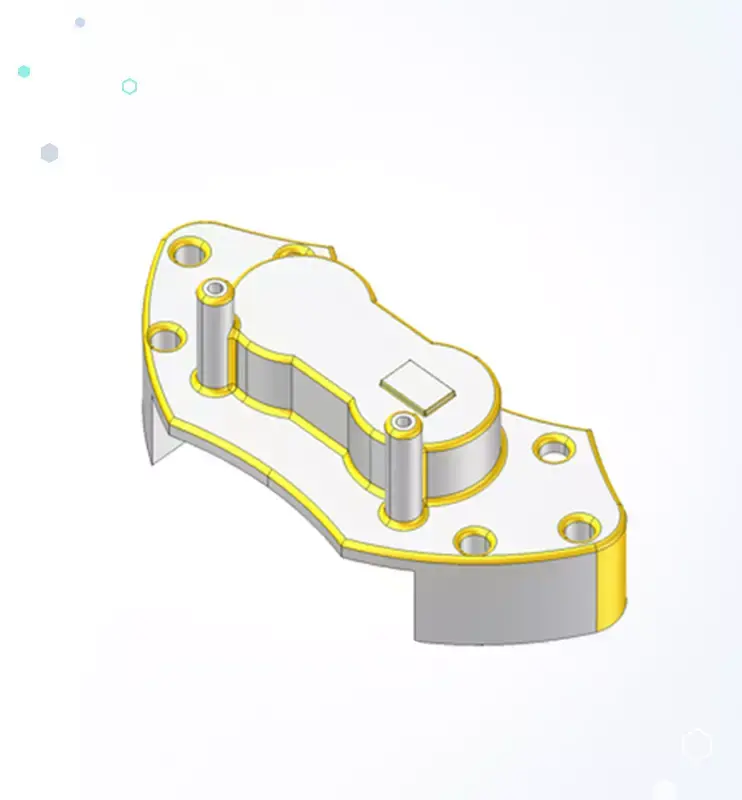

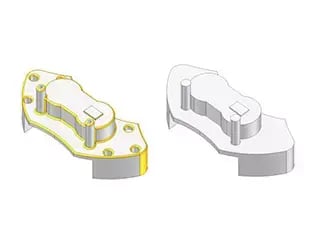

Advanced Feature Recognition

Automated Feature Identification for Manufacturing

CGM Modeler delivers cutting-edge feature recognition, identifying manufacturing features such as fillets, holes, pockets and pads. This allows CAD/CAM applications to automate design modifications, focusing on efficiency and precision in the manufacturing process.

High-Quality CAD Data Translation

Flawless Format Interoperability

3D InterOp provides the highest quality of CAD data translation, ensuring seamless input and reuse of existing models across different formats. This capability supports the integrity and usability of CAD data in diverse manufacturing environments.

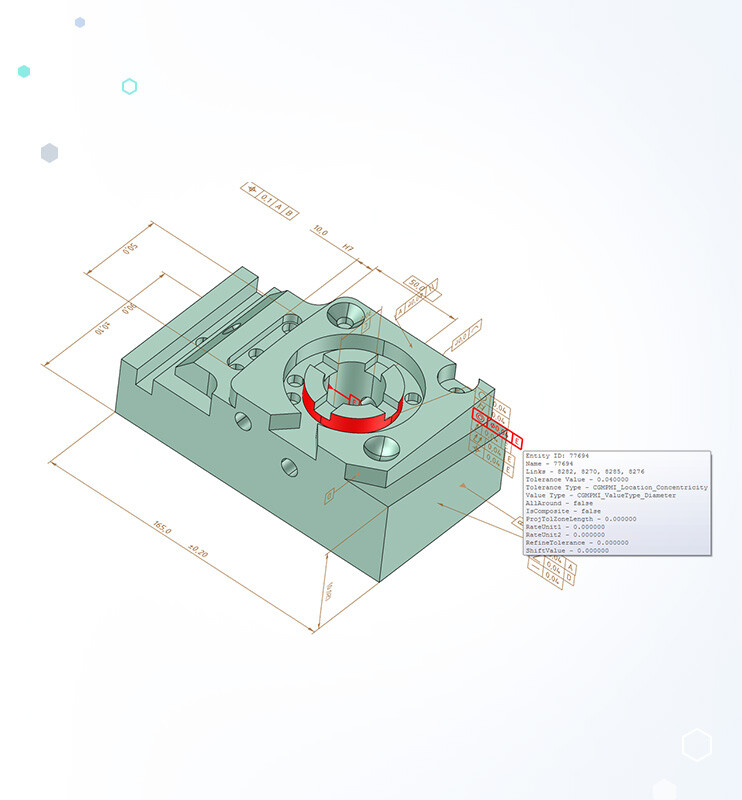

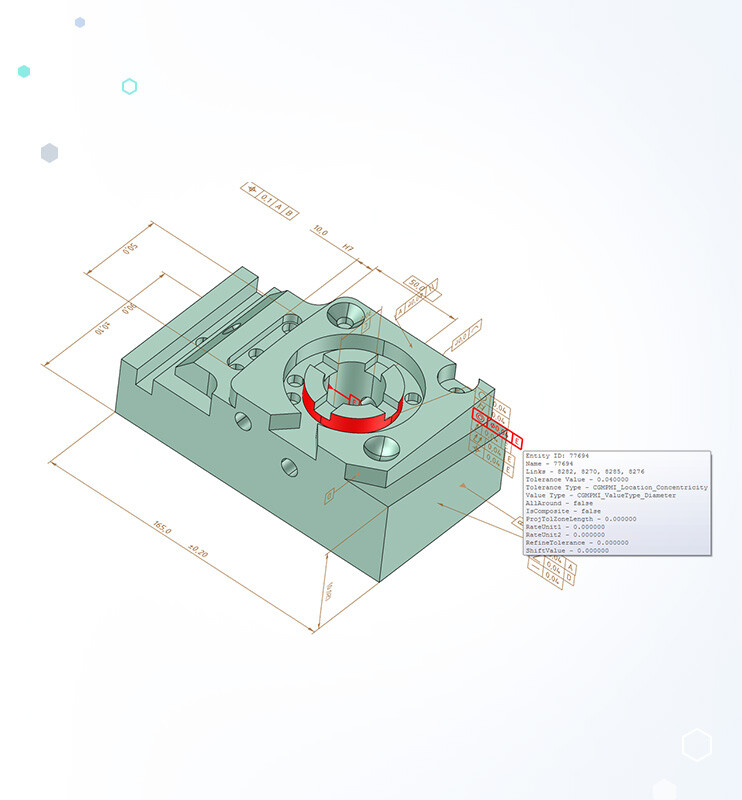

Semantic PMI Extraction and Automation

Automating Manufacturing with PMI Insights

3D InterOp enhances manufacturing automation by extracting semantic information from annotations, including symbolic threads. This allows for the automatic manufacturing of parts without manual input from CAM engineers, streamlining the production process.

Why Develop With Spatial SDKs?

This level of support provides you with unique benefits that carry through to your bottom line.

3D Derived Functionality

3D Production Simulations

3D Visualization and Interaction

Data Exchange is Key

Get Started With Spatial

Do we have the technology to take your 3D application workflows to the next level? Find out by speaking with a Spatial expert.

All Our Manufacturing

and Fabrication Resources

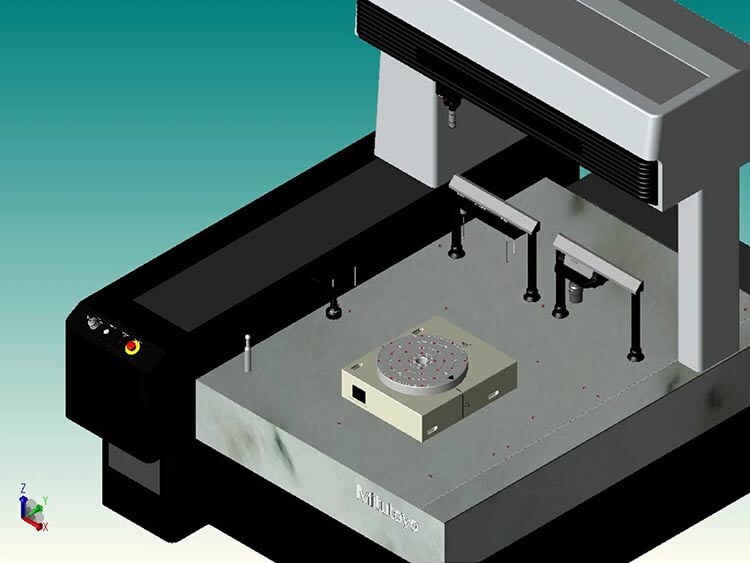

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

A 3 Part Guide for Machine Tool Manufacturers

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Quickly Detect Bends and Unfold Parts in Sheet Metal Manufacturing

Learn how your 3D application can leverage CGM Modeler’s robust automatic bend detection and unfolding capabilities.

Automated CAM Programming – Spatial & ModuleWorks

CAM software developers and machine builders can automate processes, reduce downtimes, and differentiate in the market with Spatial and ModuleWorks' expertise in automatic CAM solutions for prismatic parts.

A 3 Part Guide for Machine Tool Manufacturers

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Quickly Detect Bends and Unfold Parts in Sheet Metal Manufacturing

Learn how your 3D application can leverage CGM Modeler’s robust automatic bend detection and unfolding capabilities.

Automated CAM Programming – Spatial & ModuleWorks

CAM software developers and machine builders can automate processes, reduce downtimes, and differentiate in the market with Spatial and ModuleWorks' expertise in automatic CAM solutions for prismatic parts.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Learn How AGM Shortens Time-to-Market and Elevates Your Development

In this webinar, learn about Application Graphics Manager (AGM), its value, and how to implement it into your development process.

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Learn How AGM Shortens Time-to-Market and Elevates Your Development

In this webinar, learn about Application Graphics Manager (AGM), its value, and how to implement it into your development process.

Automated CAM Programming – Spatial & ModuleWorks

CAM software developers and machine builders can automate processes, reduce downtimes, and differentiate in the market with Spatial and ModuleWorks' expertise in automatic CAM solutions for prismatic parts.

Bring Your Assembly Modeling to Life with Parametric Constraint Management

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Expand the Scope of Your Application to Enable Hybrid Manufacturing

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Quickly Detect Bends and Unfold Parts in Sheet Metal Manufacturing

Learn how your 3D application can leverage CGM Modeler’s robust automatic bend detection and unfolding capabilities.

Technical Series: Managing Complexity with the 3D ACIS Modeler

Learn how the 3D ACIS Modeler impacts your workflow, helps reconcile design changes, and simplifies your CAD process.

Bring Your Assembly Modeling to Life with Parametric Constraint Management

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Expand the Scope of Your Application to Enable Hybrid Manufacturing

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Quickly Detect Bends and Unfold Parts in Sheet Metal Manufacturing

Learn how your 3D application can leverage CGM Modeler’s robust automatic bend detection and unfolding capabilities.

Technical Series: Managing Complexity with the 3D ACIS Modeler

Learn how the 3D ACIS Modeler impacts your workflow, helps reconcile design changes, and simplifies your CAD process.