摘要

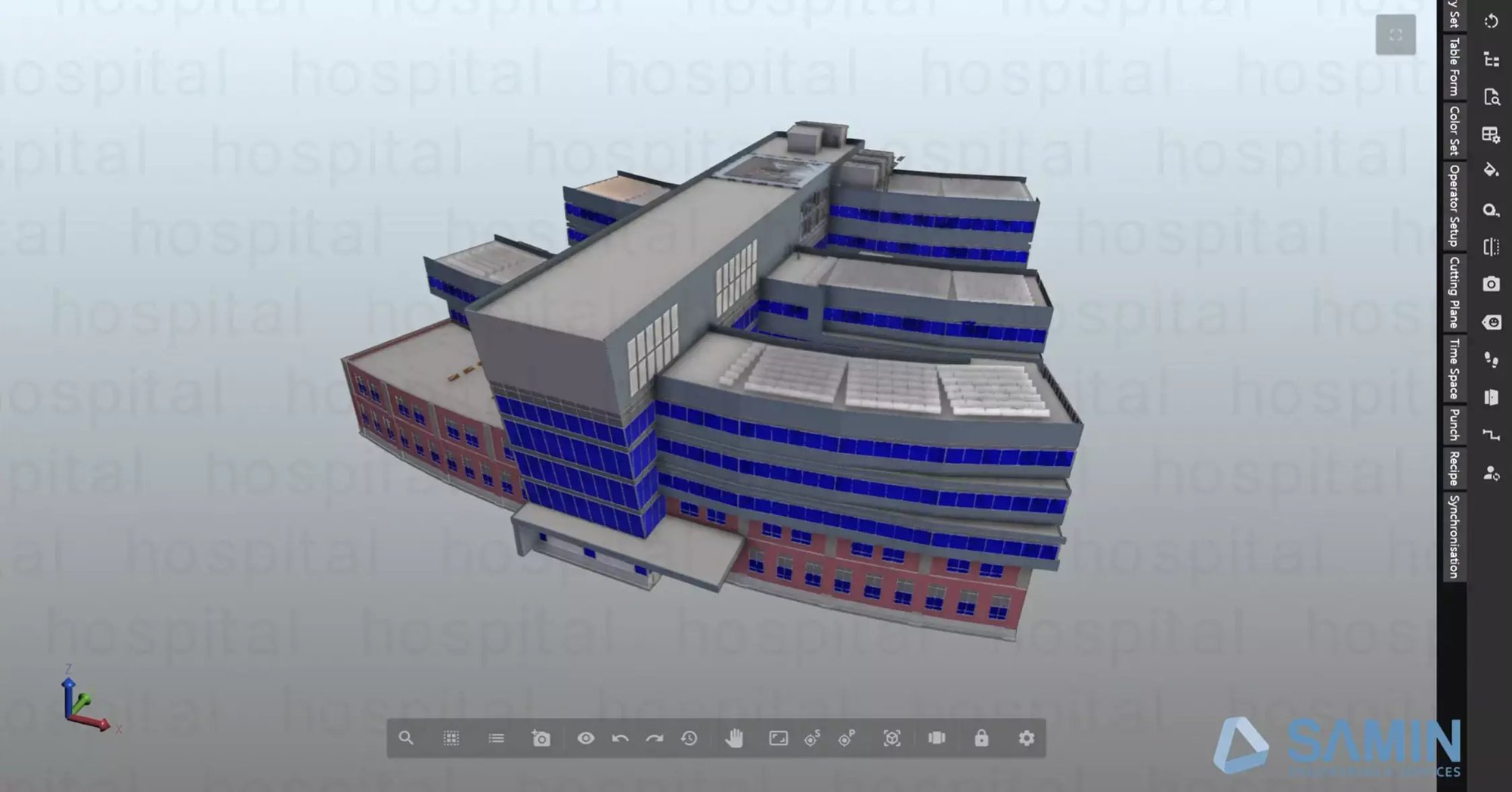

萨明信息系统公司为亚洲造船业提供尺寸精度控制和安装预测模拟系统。为了在市场上率先推出符合亚洲造船标准的三维精度控制系统,萨明需要寻找三维建模技术来开发绘图模块。

通过实施 3D ACIS Modeler、3D InterOp 和 HOOPS Visualize,萨明率先推出了符合亚洲造船市场高标准的 3D 精度控制系统。

Spatial的组件使我们能够在竞争激烈的亚洲造船行业率先进入市场。反过来,我们使客户能够加快他们的产品开发计划,同时降低成本。此外,在造船厂,现有工人可以使用我们的生态系统,通过3D模型为新工人提供高质量的培训。这使得培训新工人变得容易,他们可以快速理解他们要做什么。这真的是必须进入下一代造船业的必要功能之一。

公司

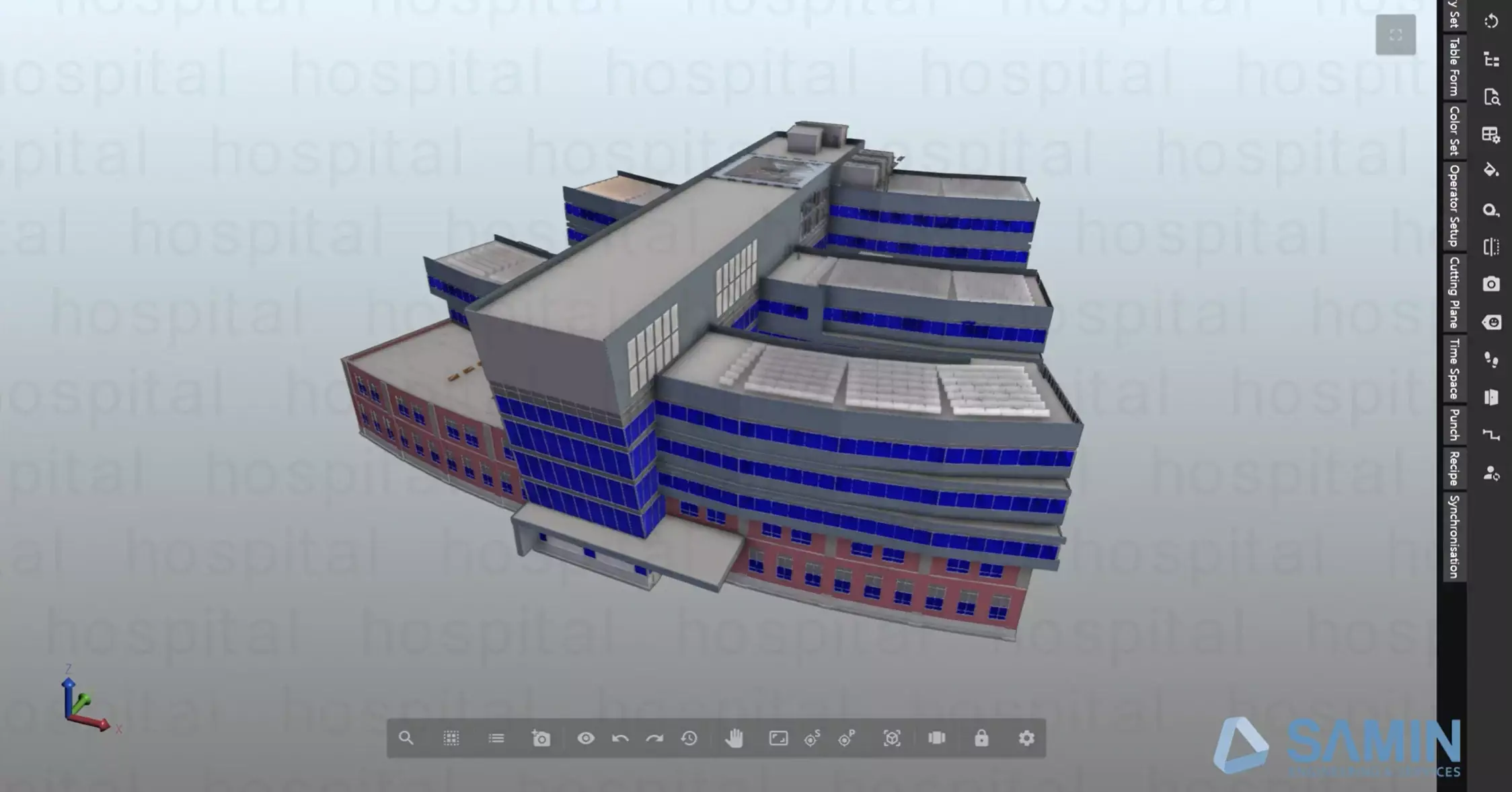

SAMIN Information System 总部位于韩国,为韩国和中国的主要造船厂提供精度控制和安装模拟系统。该公司还在日本、越南、土耳其和印度销售其产品。SAMIN 的客户包括亚洲最大的造船公司:韩国的 STX 造船海洋株式会社、上海外高桥造船有限公司、中国的大连船舶重工有限责任公司和越南的下龙造船有限公司。SAMIN 的产品系列包括用于造船生产的 EcoMES、EcoBLOCK 和 EcoOTS,以及用于造船设计的 EcoVIEWER 和 EcoPINJIG。

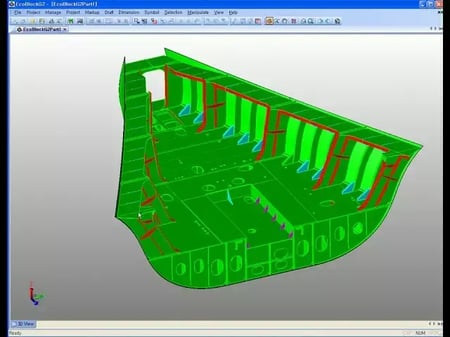

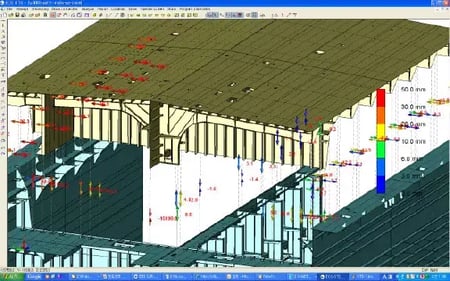

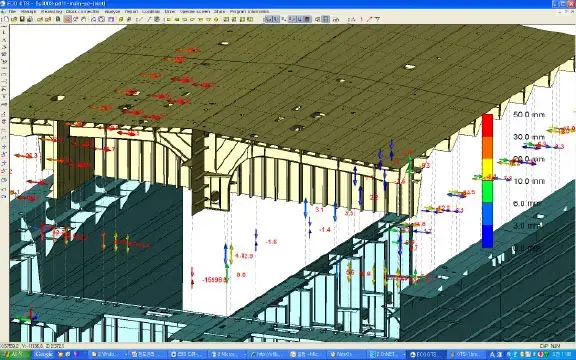

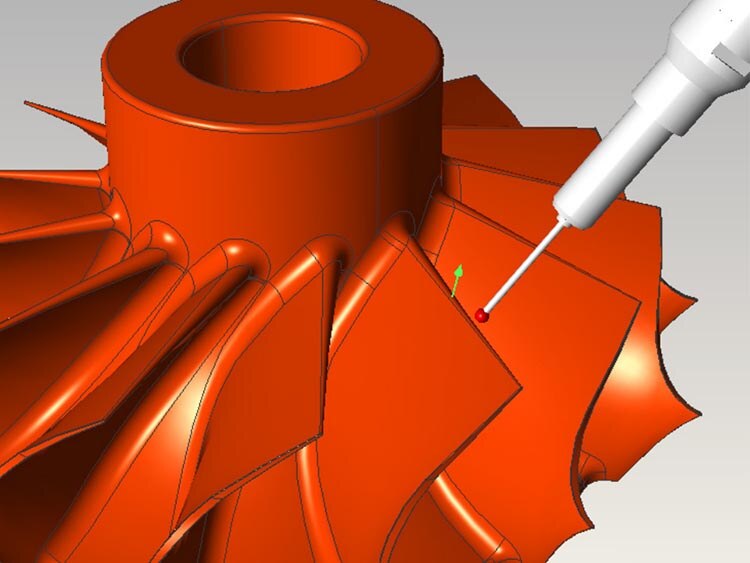

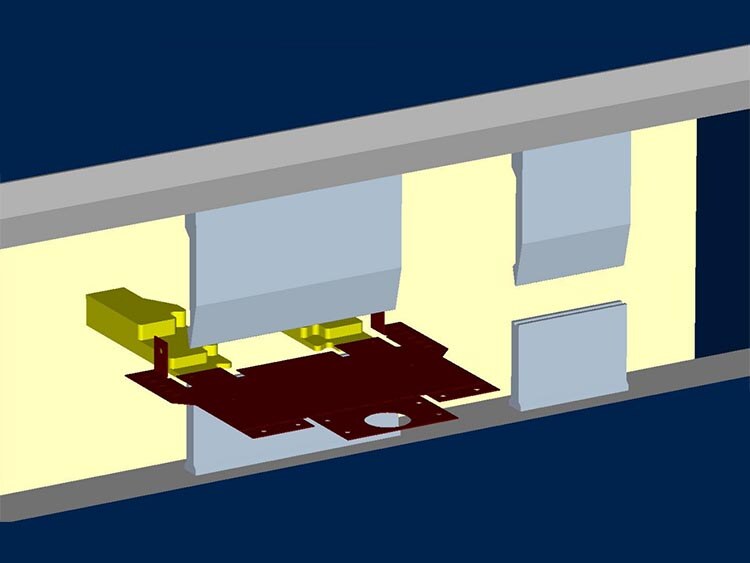

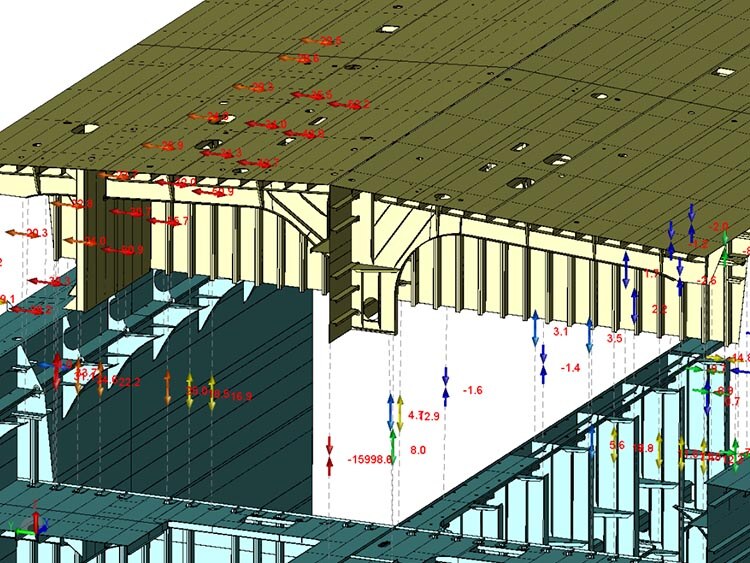

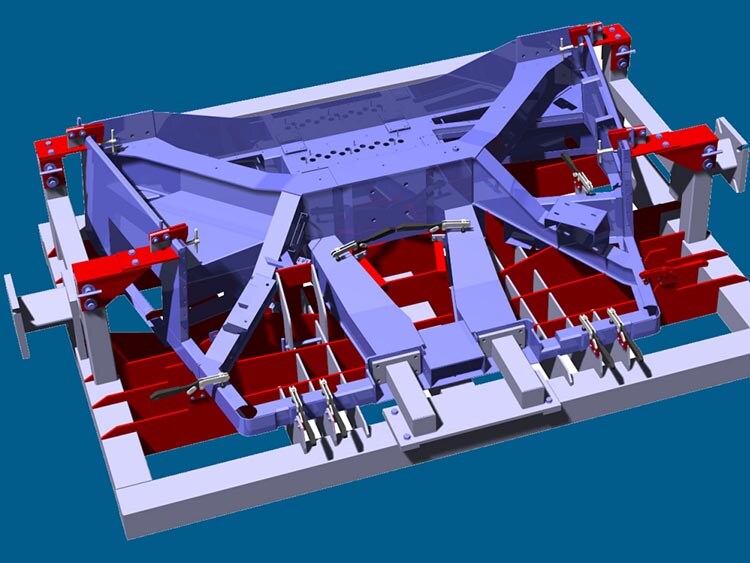

SAMIN 的 EcoBLOCK 是基于三维的分块精度控制系统,可与 AVEVA MARINE、Tribon、CADDS、ERSPD、ShipConstructor 和 AutoCAD 等造船三维 CAD 系统连接。通过使用 EcoMES 和全站仪,可对生产中的块(由不同尺寸和形状的钢板和型材组成)进行以下测量

精确测量,并与三维 CAD 系统创建的导入设计模型进行比较,从而轻松准确地分析出任何误差。利用 EcoBLOCK 的分析输出结果,可为任何需要通过切割和翻转进行修正的砌块推导出修正方法。输出结果可用于生产精确满足船东要求的木块。

挑战

寻找强大的三维建模内核

为了率先推出符合亚洲造船标准的三维精度控制系统,SAMIN 需要寻找三维建模技术来开发绘图模块,并从 Tribon 提取三维设计信息(几何、属性)。在寻找组件解决方案之前,该公司一直在进行内部开发工作。

.webp?width=450&name=maxresdefault%20(1).webp)

解决方案

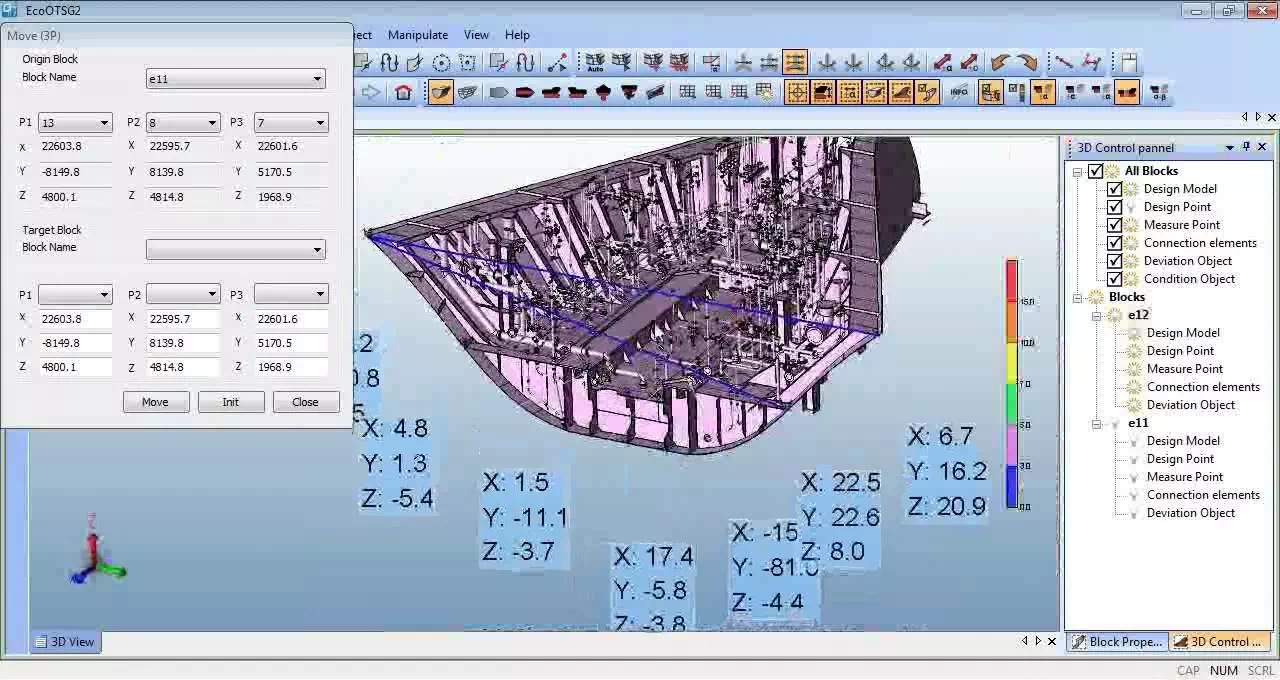

SAMIN 通过《使用 ACIS 进行 3D 建模》一书发现了 Spatial 公司。在考虑了 Parasolid 内核之后,2007 年初,SAMIN 决定 Spatial 的 ACIS 3D 建模内核和 HOOPS 应用程序框架将是其 3D 精度控制系统的最佳解决方案。

选择 ACIS 的一个主要因素是基于 ACIS 的造船应用非常普遍。亚洲的造船厂使用专门为建造大型复杂船舶和近海船只而开发的设计系统。这些三维设计程序通常基于 Spatial 的 ACIS 内核,这在很大程度上影响了 SAMIN 购买 ACIS 的决定。使用 ACIS 可确保 EcoBLOCK 和 EcoOTS 与所有领先的造船 CAD 系统相互协作,能够利用所有船舶组件术语,如管道、面板、结构的名称以及测量数据本身。

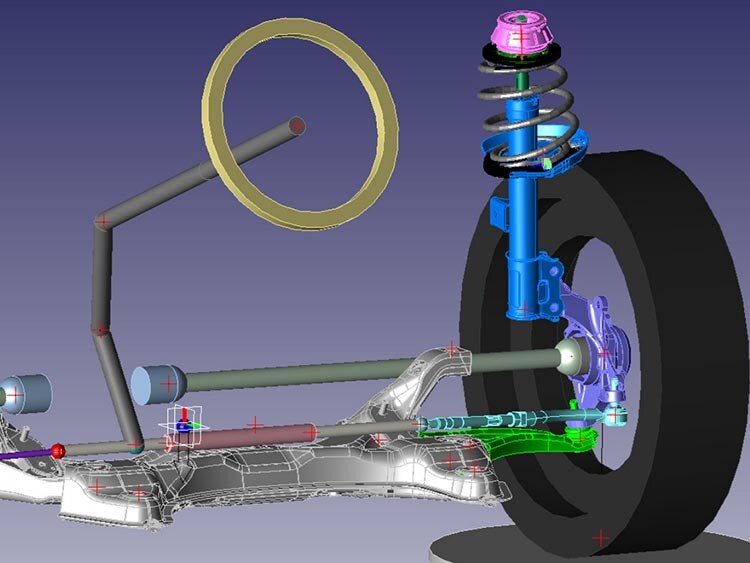

利用 ACIS 开发 SAMIN 精确度控制系统的另一个主要考虑因素是其交叉功能,该功能可在装配过程中检测船块的干扰。此外,ACIS 还可根据 Tribon(用于设计商业和海军舰船的 3D CAD 系统)的几何数据,帮助构建船块的 3D 实体模型。

HOOPS 的开放式架构和强大的图形功能使 SAMIN 能够快速开发和维护其高性能三维可视化应用程序。该公司特别发现,HOOPS 的参考应用源代码大大加快了开发进程。

结果

通过将 Spatial 的三维建模内核纳入其精度控制系统,萨明能够快速开发其软件并率先推向市场,满足造船业的特殊需求。客户的反响非常积极,认为萨明的技术具有突破性,使造船商能够以更少的劳动力更快地建造船舶,从而降低成本。

目前,萨明在其软件产品中使用了约 40% 的 ACIS 功能,并计划在未来的版本中纳入更多 ACIS 的强大功能。

重要见解

解决方案

SAMIN 认为这些Spatial功能是其软件取得成功不可或缺的因素:

-

根据代码构建船体的 3D 实体模型

-

使用 ACIS 生成 Tribon 几何数据

-

使用 HOOPS 实现三维船舶模型的可视化

-

使用 ACIS/HOOPS 进行三维船舶模型的平移和旋转

-

获取三维船舶模型坐标

-

使用 ACIS 检测船舶部件之间的冲突

-

使用 HOOPS 实现各种标记的可视化

阅读更多Spatial案例研究

了解我们行业领先的 SDK 如何帮助多个垂直领域的无数企业。浏览

我们的其他案例研究。

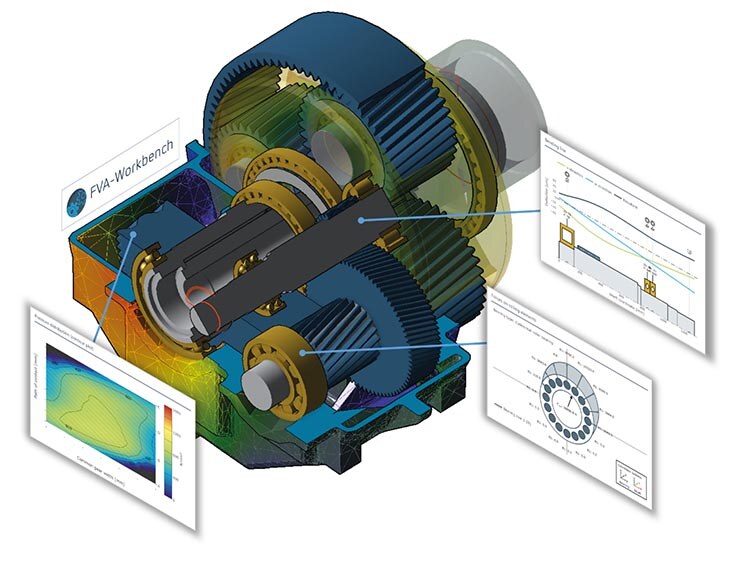

Stäubli借助Spatial SDK提升产品与能力

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

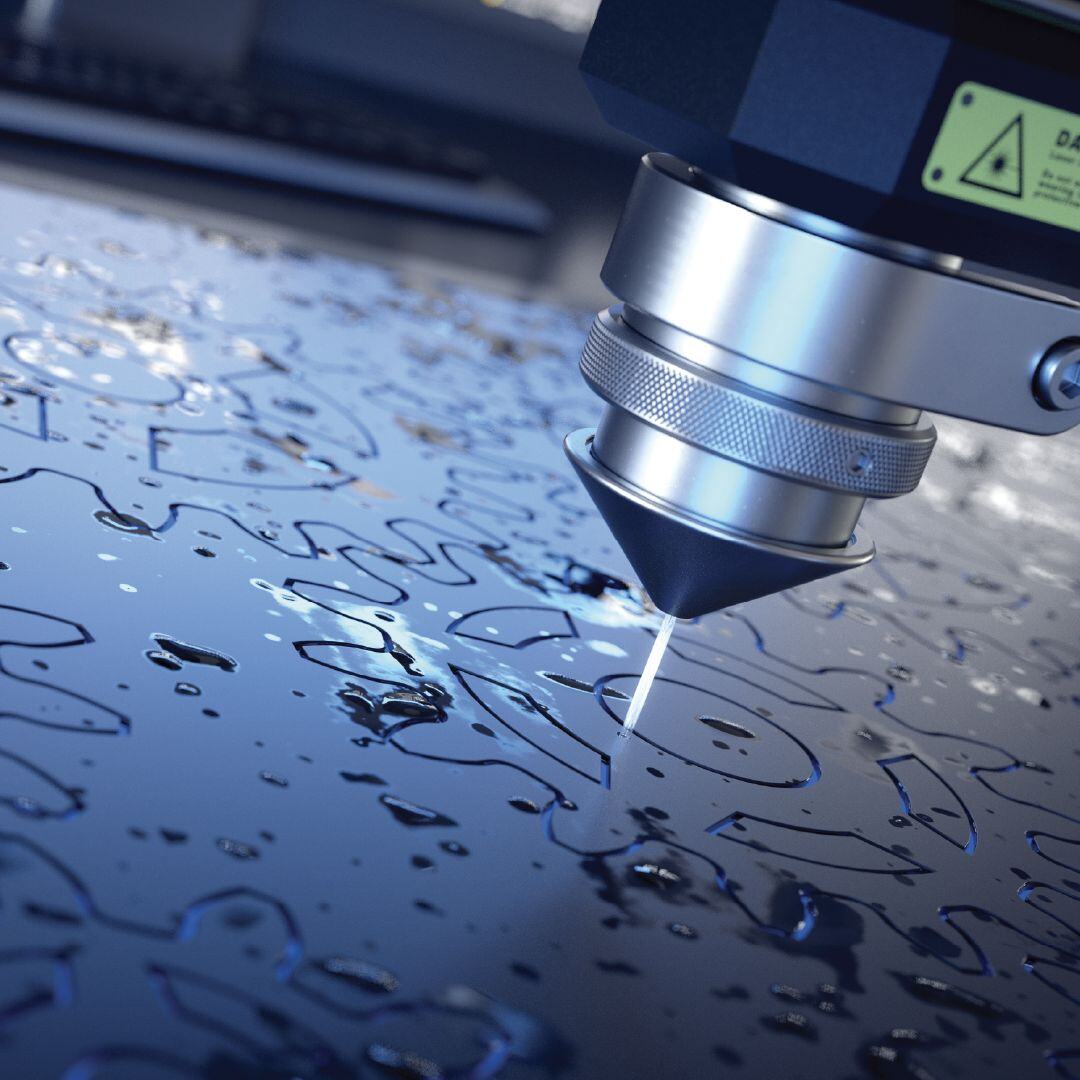

Prototek推出先进数字化制造报价系统

Prototek IQ借助Spatial组件,实现了对3D模型的即时报价,节省客户时间,减轻管理负担,并为数字化制造开辟新机遇。

-1.png)

Coreform推出革命性仿真软件

Coreform决心在CAE领域产生真正影响。通过集成定制化的Spatial SDK,Coreform完善了其革命性软件。

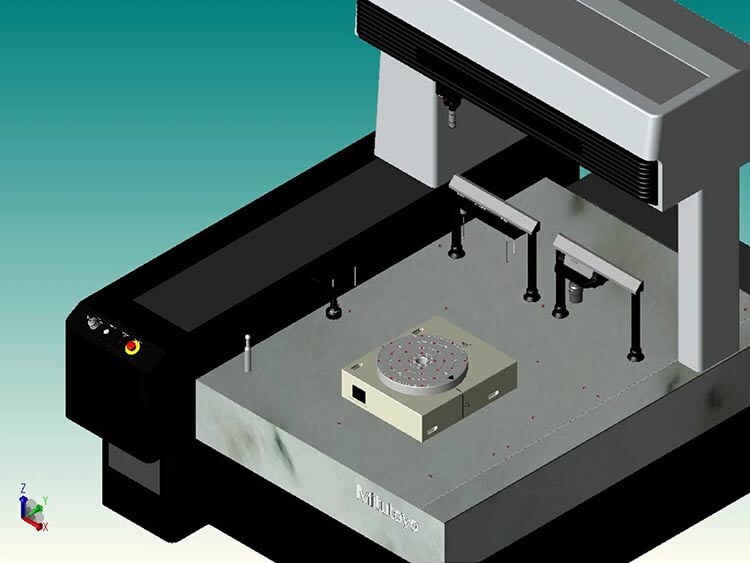

LK Metrology确保应用未来无忧

LK Metrology致力于保持其坐标测量机的精度。通过与Spatial的开发合作,他们提升了核心应用功能。

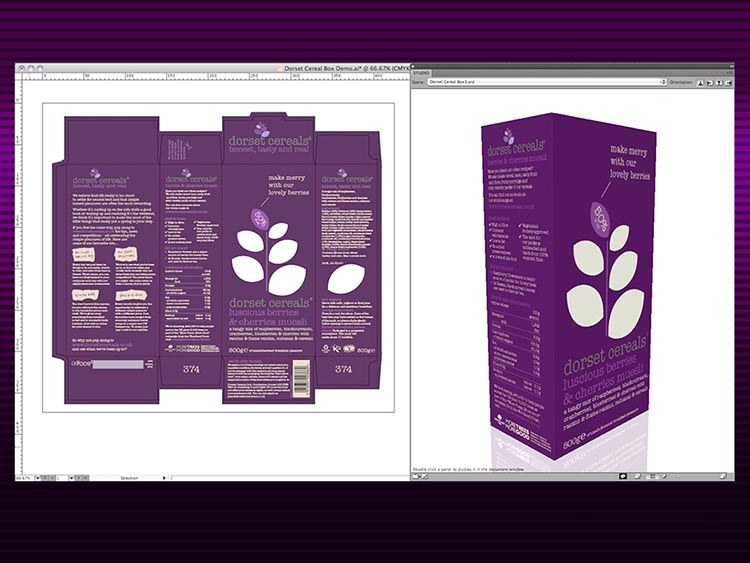

EskoArtwork大幅减少下游CAD模型准备

EskoArtware的ArtiosCAD新增3D CAD模型导入功能,保持竞争优势且不增加内部资源压力。

InnovMetric几乎消除100%翻译错误

InnovMetric通过选择Spatial InterOp软件,为汽车和航空航天客户提供PolyWorks®中的顶级CAD翻译器。

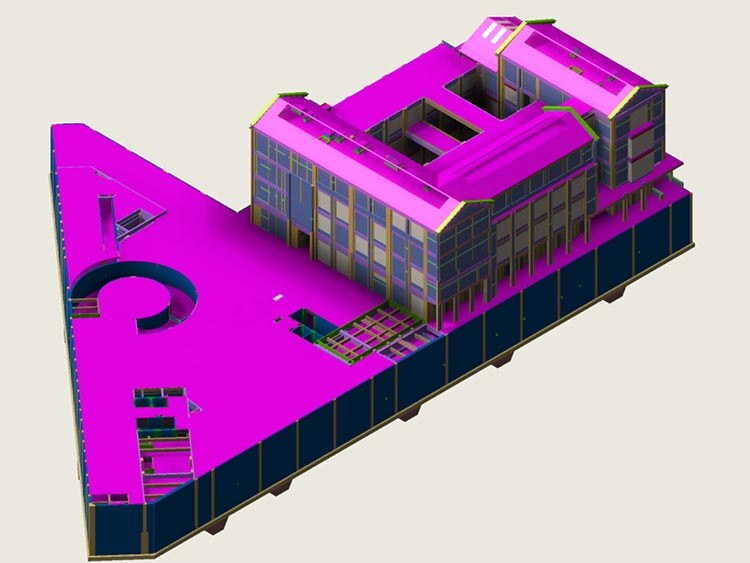

Lubansoft提升设计质量,减少昂贵错误

Lubansoft使用3D ACIS Modeler和HOOPS Visualize提升BIM软件设计质量,减少错误。

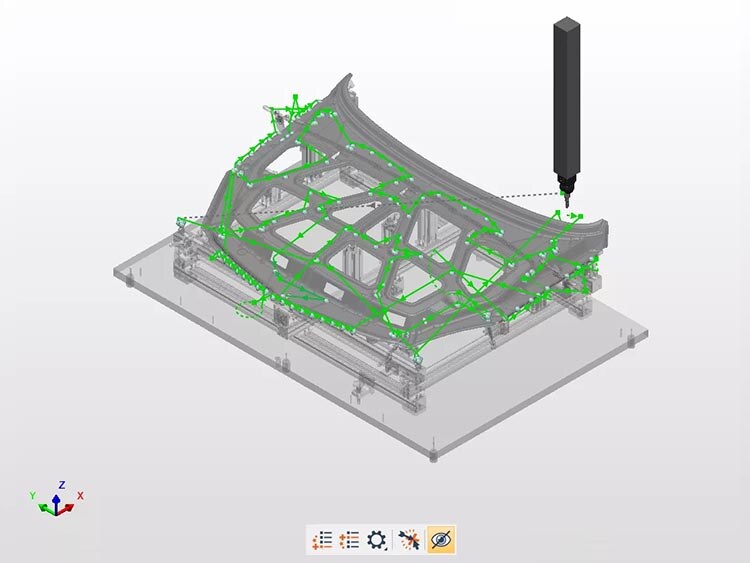

Renishaw大幅减少STL文件修复需求

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

SAMIN选择Spatial的ACIS 3D内核而非Parasolid

SAMIN于2008年率先推出符合亚洲造船市场高标准的3D精度控制系统,使用了Spatial组件。

Virtual Motion缩短50%开发时间

Virtual Motion集成3D ACIS建模引擎并利用AGM和HOOPS加速DAFUL软件开发,快速推出新产品。

XEOMETRIC加速混合与精确隐藏线移除

XEOMETRIC的2D/3D建筑规划与机械工程软件通过3D ACIS Modeler和3D InterOp获得高级功能。

TraceParts增强3D网页查看器功能

知名CAD内容供应商TraceParts在其在线3D零件查看器中集成了强大的3D可视化功能,以提升客户订购体验。

Treble Technologies通过自动3D网格化简化仿真

Treble Technologies通过集成Spatial的Meshing SDK加速仿真流程,实现更快、高保真的大规模声学仿真。