Rapid and Reliable on Complex Models

CGM HLR excels in efficiently handling large and intricate models, ensuring quick and dependable performance.

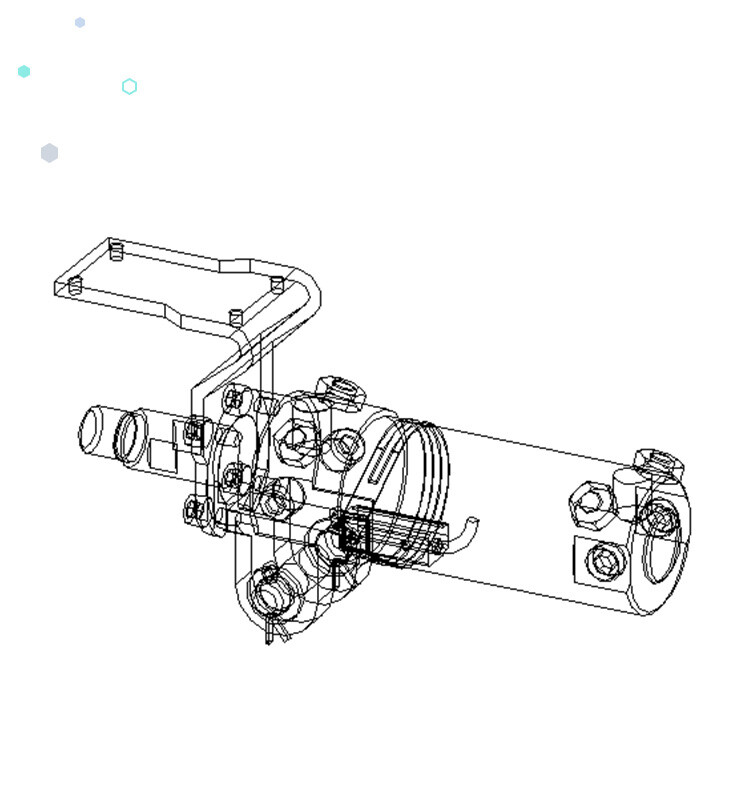

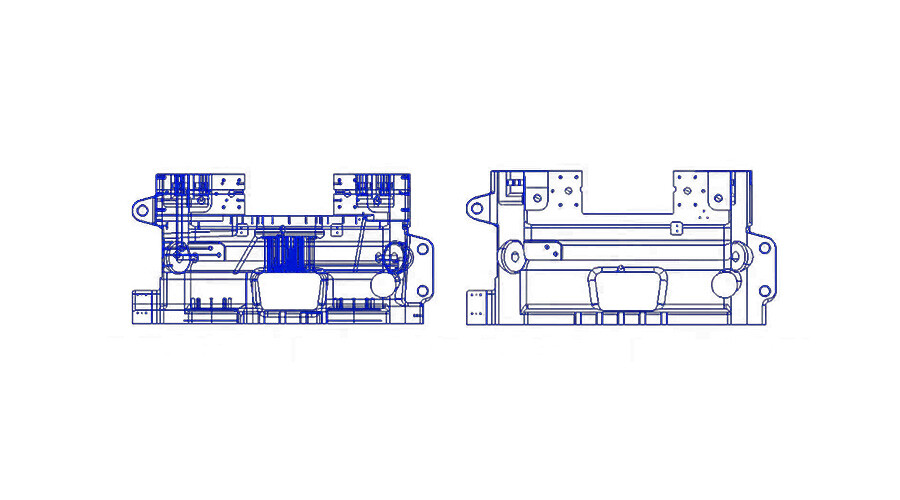

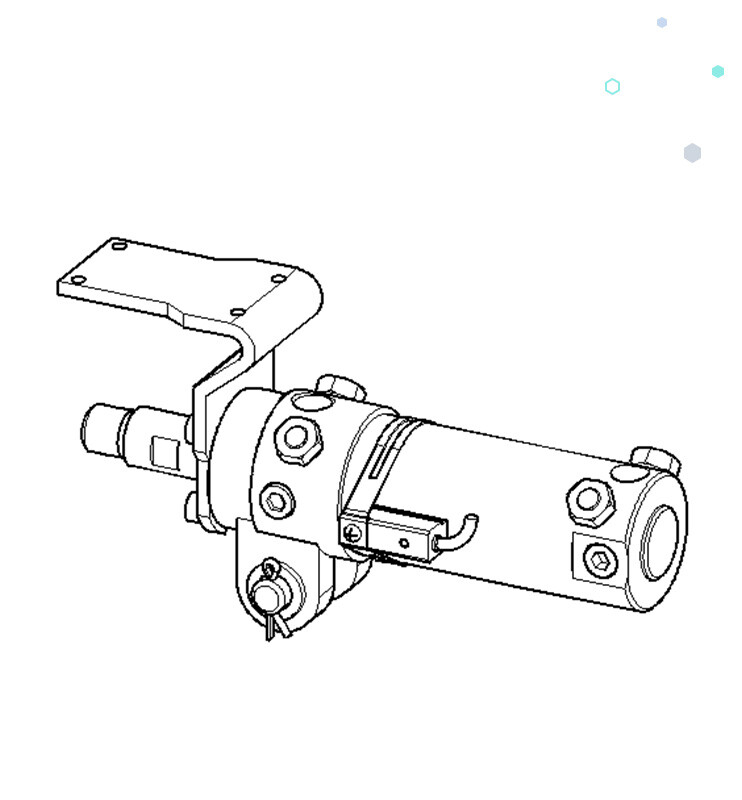

CGM HLR (Hidden Line Removal) allows you to produce easy-to-interpret drawing data by calculating visible, hidden, silhouette and occluded lines of a 3D model from different perspectives. This feature is crucial for producing clear and precise 2D drawings from complex 3D designs, making it invaluable for industries requiring detailed technical illustrations.

CGM HLR transforms your 3D designs into precise, easy-to-interpret 2D drawings. By calculating visible, hidden, silhouette and occluded lines from various perspectives, CGM HLR ensures your technical illustrations are clear and accurate.

Perfect for industries demanding detailed technical drawings, CGM HLR offers rapid and reliable performance, even with complex models. Its versatility allows you to generate dimensions and analyze models from specific view angles, providing precise hidden line results. Enhance your workflow and present your designs in the most informative way with CGM HLR.

CGM HLR excels in efficiently handling large and intricate models, ensuring quick and dependable performance.

Quickly produce 2D drawings from any 3D design, enhancing your workflow with accurate hidden line views.

Spatial offers essential functionality within an application infrastructure for quick and seamless implementation, saving you time and effort.

Discover the full potential of CGM HLR. Download our comprehensive product data sheet to learn more about our robust 3D application framework.

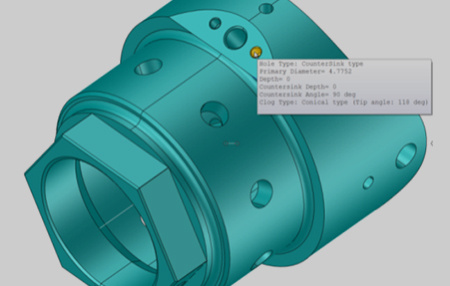

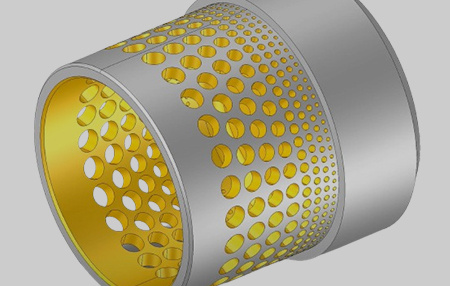

The ultimate modeling technology for the next generation of 3D applications. Create, modify, query and visualize 3D data with CGM Modeler.

Benefit from groundbreaking additions to precise modeling, such as automated healing, data preparation and data analysis.

Deliver automation in your application by removing hole or fillet features in one step without requiring user input.

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Discover Automatic CAM, the enabling processes, and its application benefits.

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

A 3-part guide for Machine Tool Suppliers on boosting hardware sales through software differentiation and choosing the right development toolkit.

Discover Automatic CAM, the enabling processes, and its application benefits.

Explore the top reasons to use Spatial's 3D SDK for developing, deploying, and supporting innovative 3D applications.

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

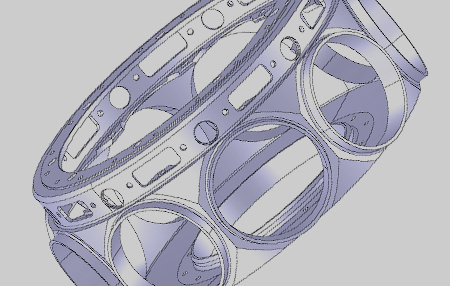

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

Learn why companies transition from homegrown graphics solutions to HOOPS Visualize and what the switch entails.

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

Understand model repair and validation, its impact on modeling operations, and detailed test results.

Learn how CGM Modeler enables application development for creating, modifying, querying, and visualizing 3D data across industries.

Explore current and future Computer-Aided Manufacturing workflows and ways to enhance CAM.

Discover the importance of 3D model healing, pre-healing actions by 3D InterOp, and the healing process.

Understand model repair and validation, its impact on modeling operations, and detailed test results.

Learn how you can significantly speed up your application’s development with AGM’s extensive, out-of-the-box, advanced code base.

Discover how Application Lifecycle Management impacts your revenue, shortens time to market, and extends your application's lifespan.

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover how to handle both CAD and scanned data for hybrid manufacturing.

Discover how Application Lifecycle Management impacts your revenue, shortens time to market, and extends your application's lifespan.

Learn how you can enable constraint management and assembly modeling in your 3D application with Spatial’s Constraint Design Solver SDK.

Discover how to easily add simulation to your application or automate interface detection in CHT or CFD simulation applications.

Discover how to handle both CAD and scanned data for hybrid manufacturing.