COSCOM Case Study

Market: Manufacturing, CNC Machining, Metalworking, Mechanical, Engineering

Summary

The collaboration with Spatial has been central to COSCOM’s evolution from 2D to 3D tool data management solutions. Beginning in 2003 with 3D ACIS Modeler for their CAD/CAM ProfiCAM VM software, this partnership spanning over 20 years has grown naturally with each product integration. After 3D InterOp enabled multi-CAD compatibility, the recent Data Prep Add-On integration delivered breakthrough data optimization capabilities.

The new TCI Data Preparation module within ToolDIRECTOR VM provides an automatic one-click solution for CAD data simplification. With Data-Prep Add-On, COSCOM reduces the amount of facets in tool drawings and fixtures, depending on the data by up to ca. 50 %, while automatically retaining critical features like cutting edges for collision checking and simulation. This makes digitalization accessible beyond highly skilled engineers, helping COSCOM’s European customer base reduce time, data volume, and stress in their CNC machining operations.

With Data Prep, we are able to reduce the amount of detail, the amount of facets, for example, in tool drawings or fixtures. With a one-click solution, our customers can prepare for future needs and make the process more comfortable and faster.

The Company

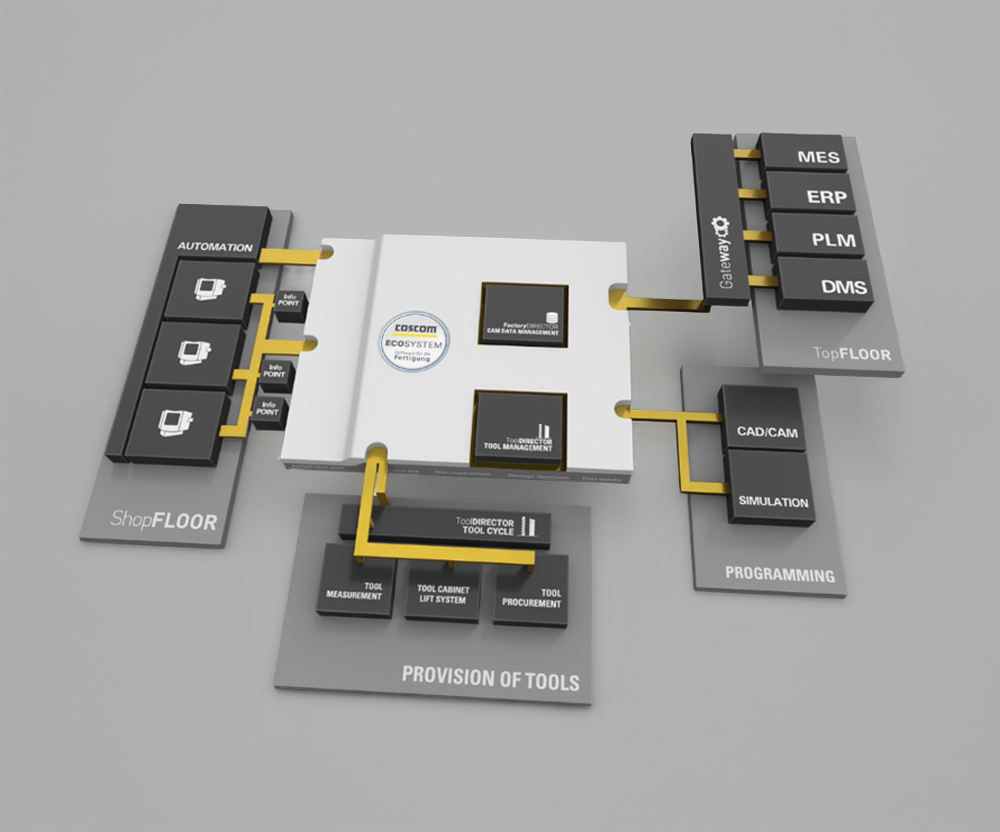

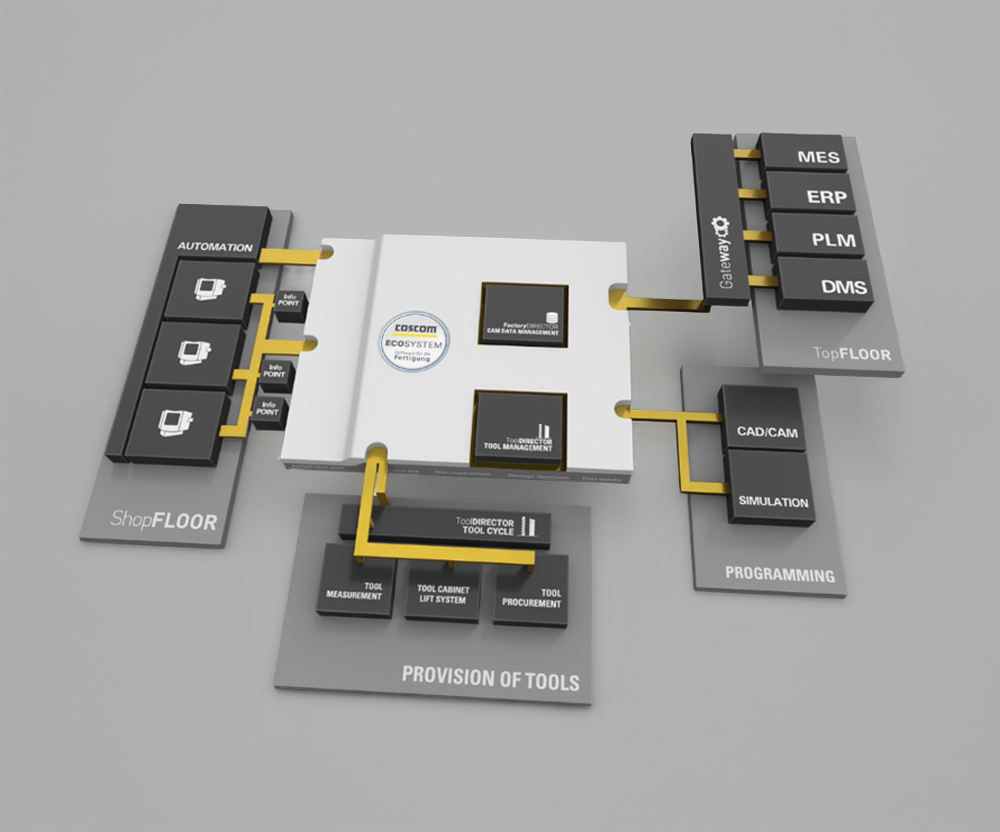

Since 1978, COSCOM Computer GmbH has been a leading software provider developing and integrating products and process solutions for process optimization in the metalworking and mechanical engineering industries. Under the leadership of managing directors Knut Mersch and Christian Erlinger, COSCOM develops solutions that enable machinery and mechanical engineering companies to optimize their CNC processes. COSCOM’s solutions cover the entire chain from CAD/ CAM through simulation to tool management and data management, particularly for milling and lathe machines. The core product portfolio has a modular structure consisting of CAD/CAM software, machine simulation, tool management, CAM data management, DNC software, and associated process consulting.

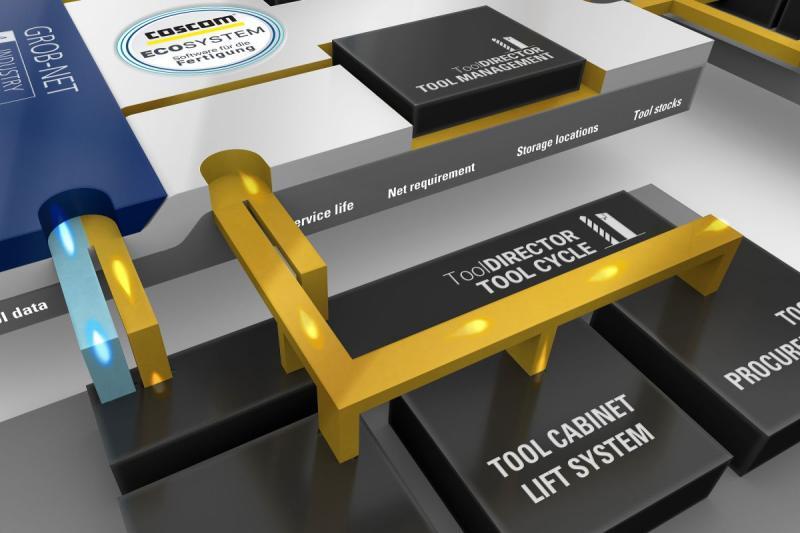

COSCOM’s flagship ToolDIRECTOR VM (Virtual Machining) is a modular software solution providing comprehensive tool management support for milling machines and lathes. The solution transforms CAD data from various tool manufacturers and in-house tool designs into digital twins for CNC machines, supporting multiple CAD systems including AutoCAD, Autodesk Inventor, CATIA V5, Siemens NX, SOLIDWORKS, and many more. Serving customers from diverse sectors where metal processing is part of their business—without focusing solely on automotive or defense—COSCOM maintains a comfortable market position with an established customer base across Europe.

The Challenge

Massive Data Volumes Affecting Application Performance

One major challenge for digital twin applications in CNC manufacturing has been the massive data volume inherent in detailed tool geometries. The large number of fine geometric details—such as internal structures—significantly affects application performance in every CAD/CAM software. This creates obstacles for customers seeking efficient collision avoidance at the machine level and smooth digital process integration into their daily operations.

The Critical Balance: Detail Reduction Without Information Loss

The technical challenge was clear: while some geometries must be retained for collision checking and simulations, many details are not essential for the digital twin. For example, the internal structure of a bore does not contribute to simulation accuracy but adds computational burden. The question of data volume in simulations and collision avoidance systems is always critical—how much detail is truly necessary versus what creates unnecessary processing overhead? Reducing fine details such as facets in tool drawings or fixtures leads to data minimization and improved performance, but required an intelligent approach to ensure critical information was preserved. COSCOM needed a solution that would help customers prepare for future digitalization projects and make the process more comfortable and faster, while making digital and technical challenges accessible beyond highly skilled engineers.

The Solution

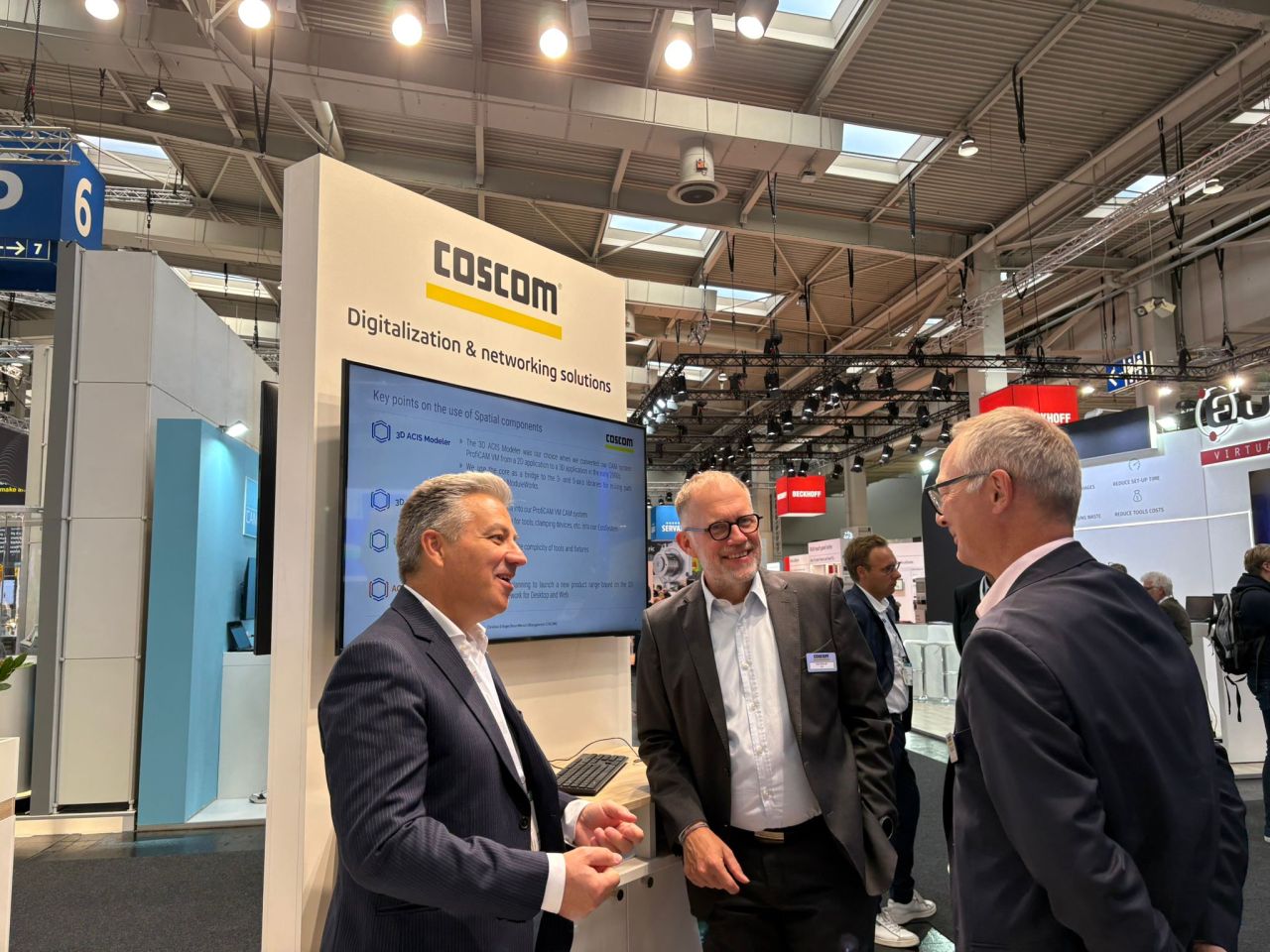

A Valued Partnership Built Over 20 Years

COSCOM’s collaboration with Spatial began in the early 2000s when the company sought to expand from 2D to 3D tool data in their in-house CAD/CAM software. At that time, 3D ACIS Modeler had already earned a strong reputation in the market and COSCOM was convinced that Spatial would be the right partner. The first contract was signed in 2003. COSCOM then developed ProfiCAM VM, a CAD/CAM software solution for simulating milling, turning, and turn-milling processes, using 3D ACIS Modeler as its core geometric modeling engine.

Progressive Integration: From 3D ACIS to 3D InterOp

The next natural step was implementing 3D InterOp to enable compatibility with several leading CAD systems. This integration provided reliable CAD data translation across diverse formats such as AutoCAD, Autodesk Inventor, CATIA V5, Siemens NX, SOLIDWORKS, and many more. As COSCOM’s software quality grew with Spatial’s expanding product range, each integration represented a logical progression in their digital twin capabilities. Spatial proved to be a very reliable partner with deep technical expertise, always engaged in collaborative problem-solving.

One-Click Solution Delivering Measurable Results

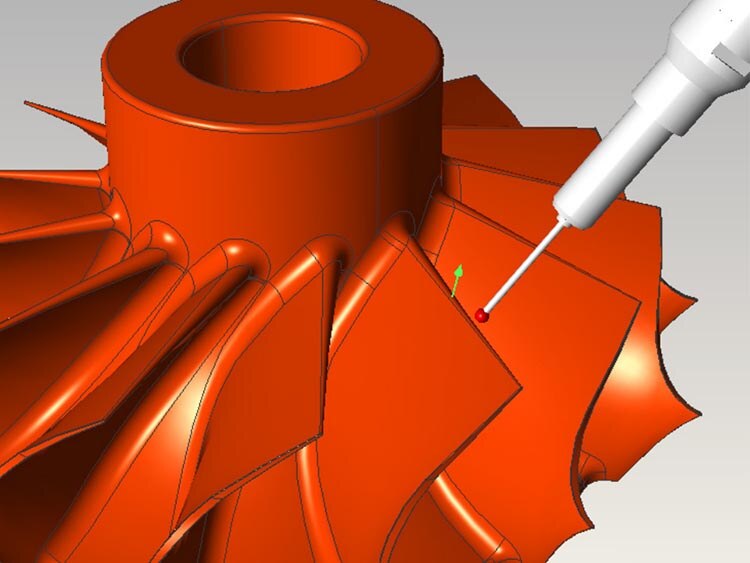

With Data Prep Add-On integration, COSCOM is able to reduce the amount of details and facets in tool drawings or fixtures with a single click. For example, in a grooving turning tool, the internal details of holes are removed while the yellow cutting edge is automatically retained, as this area remains relevant for simulation. This approach achieves approximately 47% reduction in triangles and vertices.

This allow COSCOM to create high-quality tool drawings efficiently. By reducing the quantity of facets with a one-click solution, customers can prepare for future needs and digitalization projects in their operations, such as collision avoidance at the machine level. The software helps customers integrate digital processes into their daily work, making the process more comfortable and faster while reducing time, data volume, and stress.

Key Insights

The 20-year partnership between COSCOM and Spatial demonstrates how sustained collaboration drives continuous innovation. From 3D ACIS Modeler in 2003 to 3D InterOp and now Data Prep Add-On, each integration has been a natural step responding to technical challenges and market evolution. Spatial has proven to be an essential technology partner for COSCOM, combining deep technical competence with a collaborative approach. The TCI Data Preparation module transforms digital twin accessibility. By reducing huge amount of facets with one click while preserving critical collision checking features, COSCOM makes digitalization possible for their customers and makes digital challenges accessible beyond highly specialized engineers. This aligns with their mission to help companies integrate digital processes into their daily operations.

With a strong European customer base and future plans to use AGM framework for next-generation solutions, COSCOM has positioned itself to serve diverse manufacturing sectors. The Data Prep integration helps customers prepare for future digitalization projects, making the process more comfortable and faster. Spatial remains a large part of the puzzle as COSCOM continues optimizing the entire CNC process chain.

Download the Full Case Study

Want to see a more detailed breakdown of how COSCOM utilized Spatial’s powerful components in their application? Download the full case study by clicking below.

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

COSCOM optimized CNC Digital Twins with Intelligent CAD Data Reduction

COSCOM needed an efficient solution to manage massive CAD data volumes in their digital twin application while maintaining precision for collision detection and machine simulation in CNC machining processes.

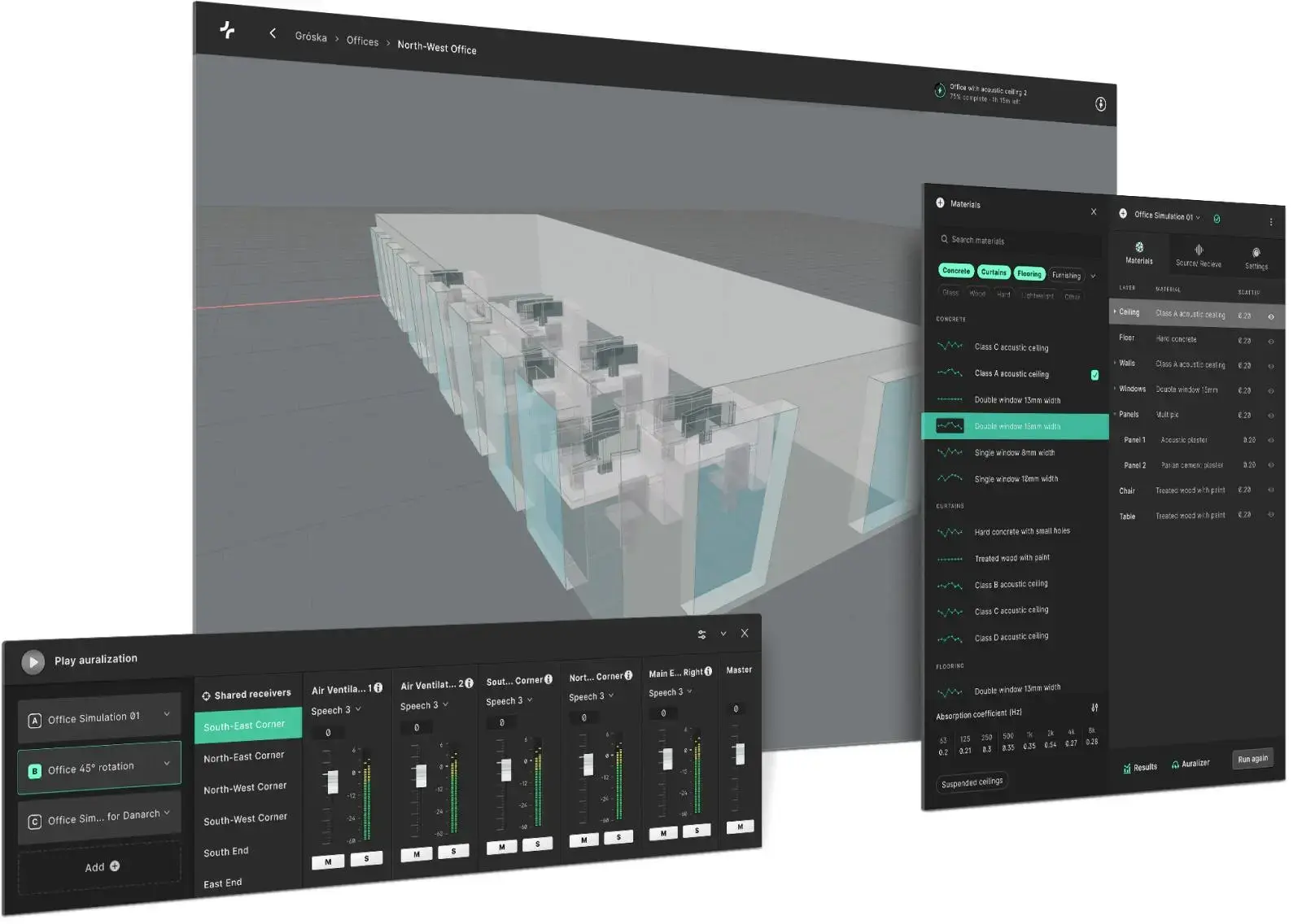

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

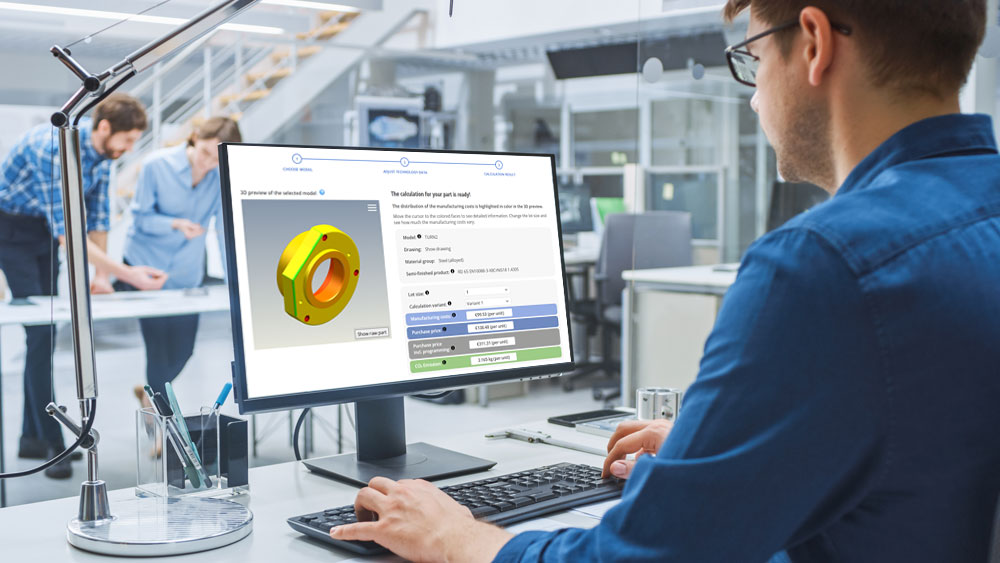

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

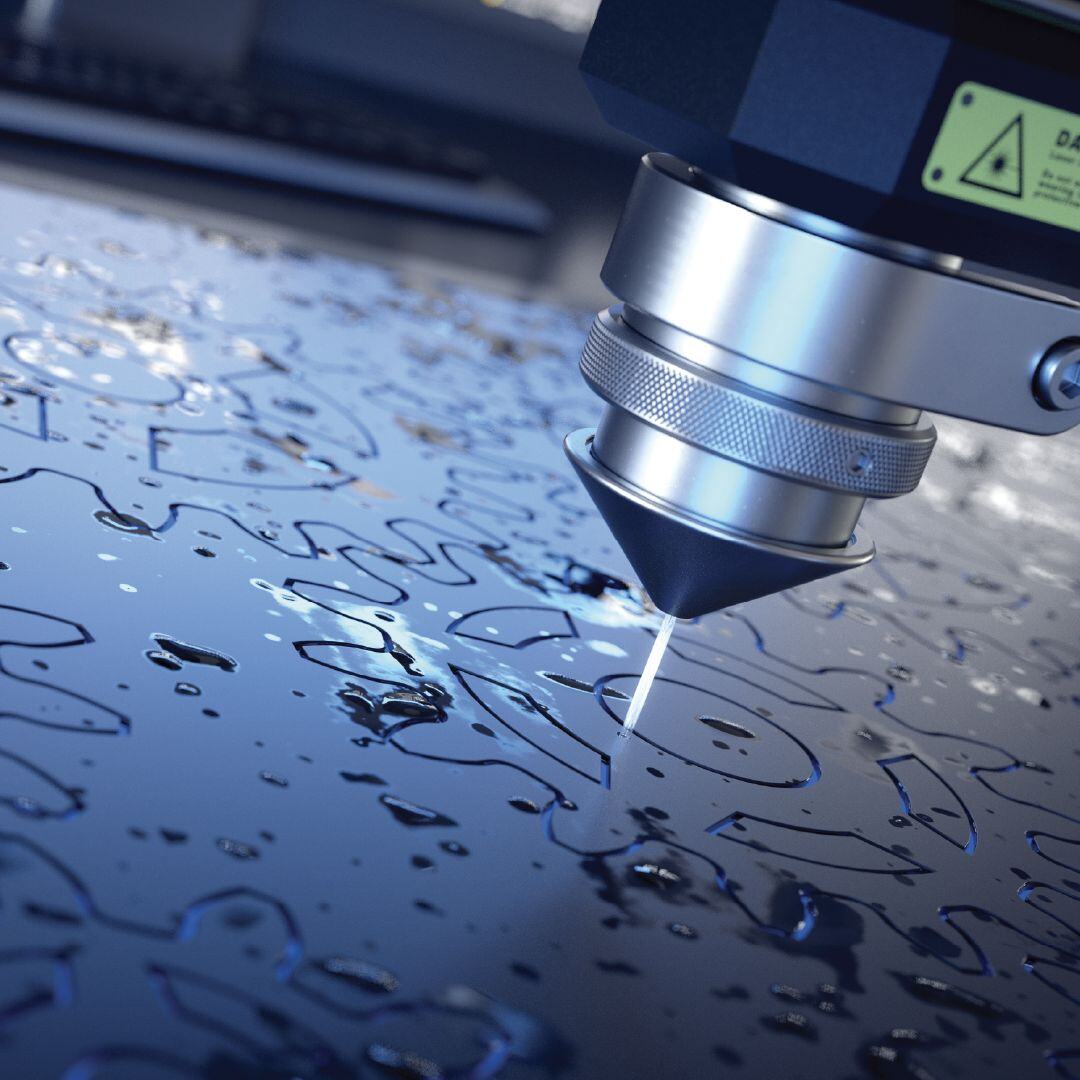

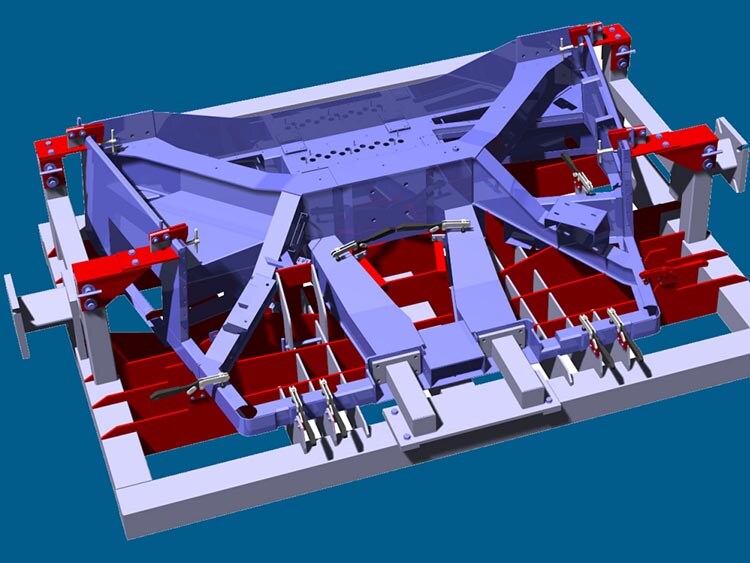

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

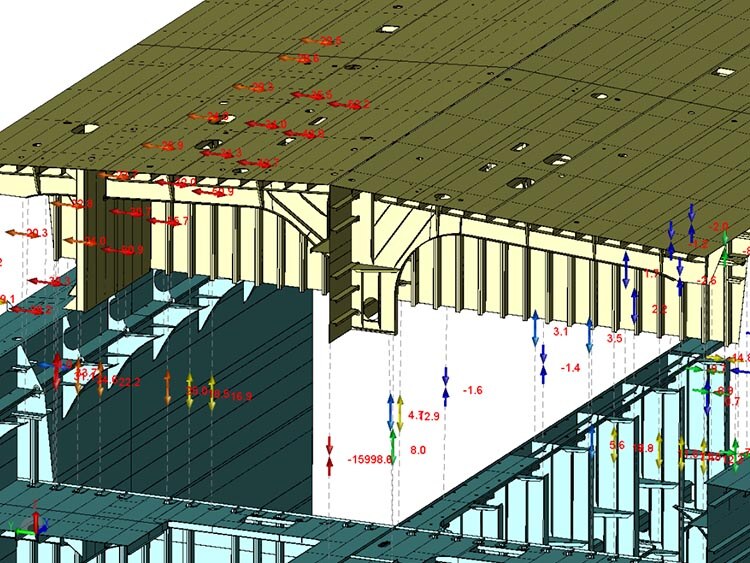

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

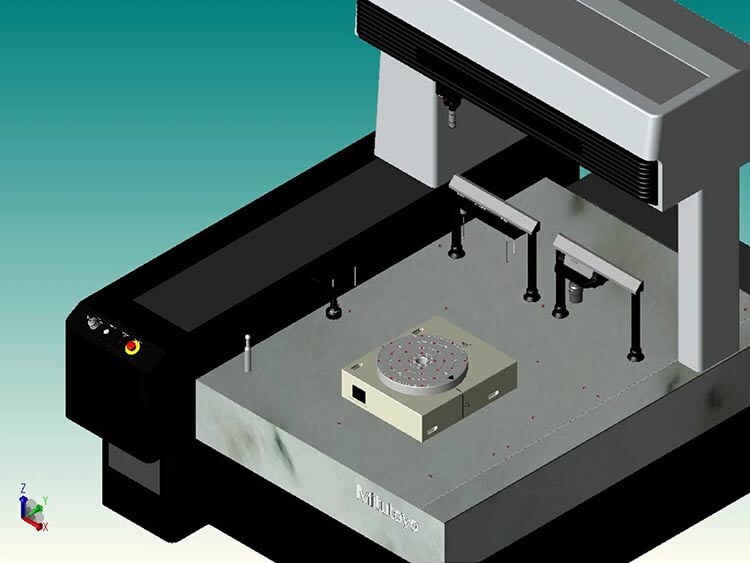

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

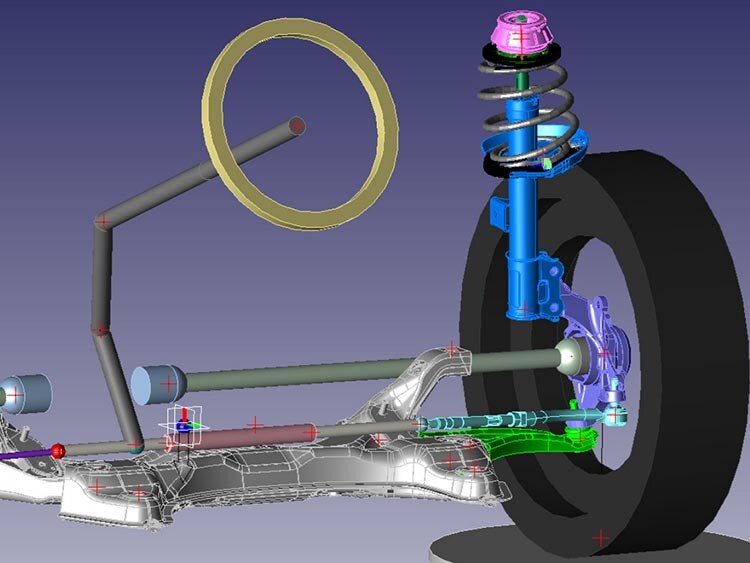

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.