Treble Technologies社 事例

Market: CAE

概要

Treble社は、スペイシャルのメッシングSDK 3D Precise Meshを導入することで、音響シミュレーションにおける高いパフォーマンスを維持したまま、顧客への納品スピードを大幅に向上しました。

このSDKによる自動かつ高精度な3Dメッシュ生成は、Treble社の革新的なシミュレーションアプリケーションとシームレスに統合され、ボリュームメッシュの品質と生成効率を最大30%改善。これにより、Treble社は顧客への価値提供に一層注力できる体制を実現しています。

With Spatial, we’ve seen clear improvements in mesh quality and data handling, which has made our simulations more reliable and streamlined the workflow. The biggest gain has been in volumetric meshing, where we estimate a 20–30% improvement in simulation efficiency.

会社概要

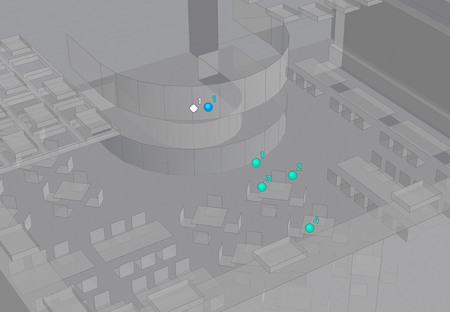

Treble Technologies社は、高精度な音響シミュレーション技術と空間オーディオ処理により、音に関する開発環境を革新しています。クラウドベースのアプリケーションやSDKを通じて、効率的かつスケーラブルな音響解析・音声データ生成を可能にし、音響の品質向上を目指す技術者を支援します。

2020年の創業以来、Treble社は急速に技術を拡張し、グローバルな大手テック企業との連携を進めています。同社のシミュレーションエンジンは、波動ベースの解析と幾何音響を組み合わせたハイブリッド構成で、広帯域の周波数に対応した高精度な音響結果を提供します。

Treble社のソリューションは、建築業界における音響技術者 、音響機器の設計開発に従事するエンジニア、ライブ会場やスタジオ設計に関わる専門家などに活用されています。L-Acousticsをはじめ、業界のリーダー企業とも連携しています。

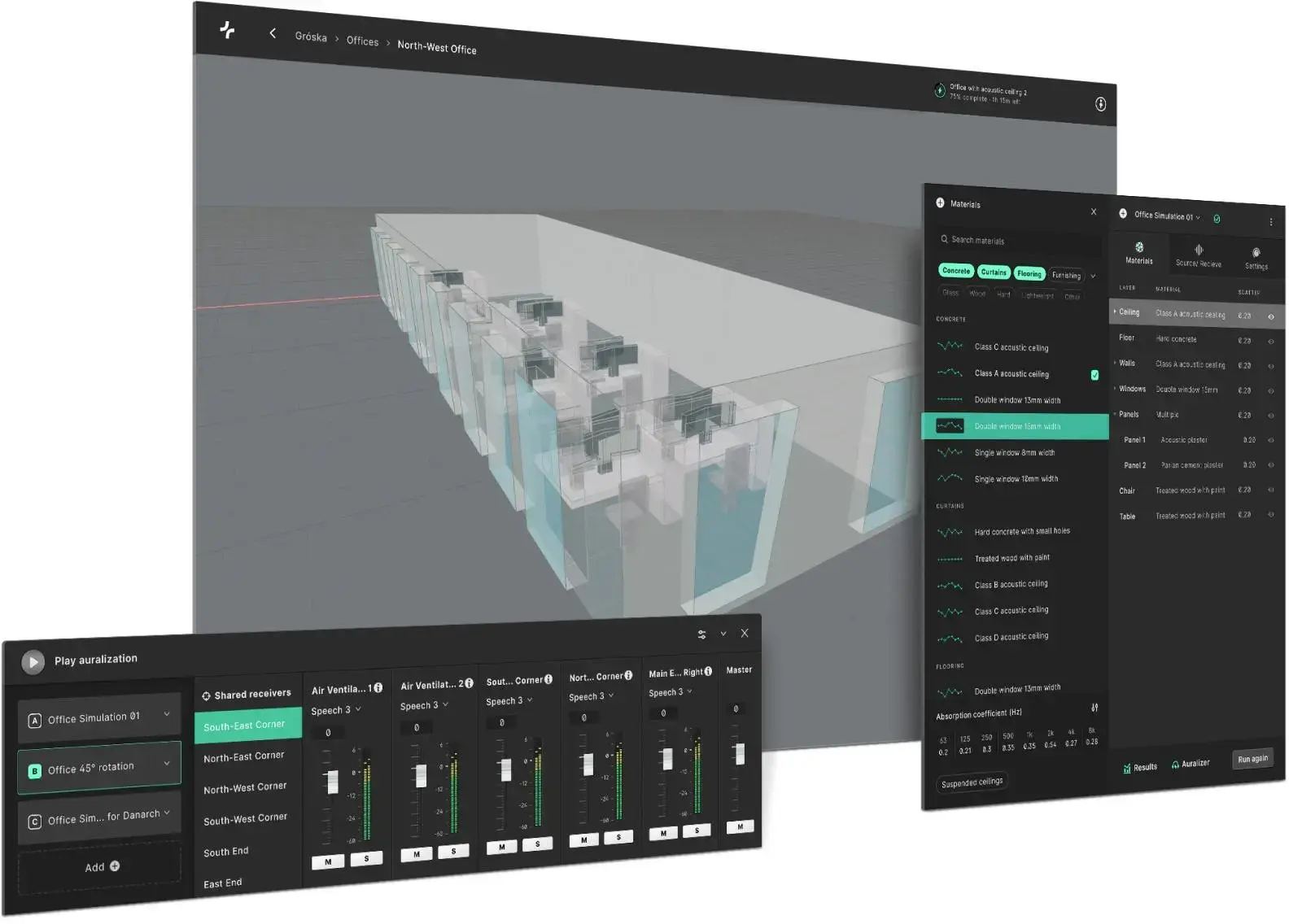

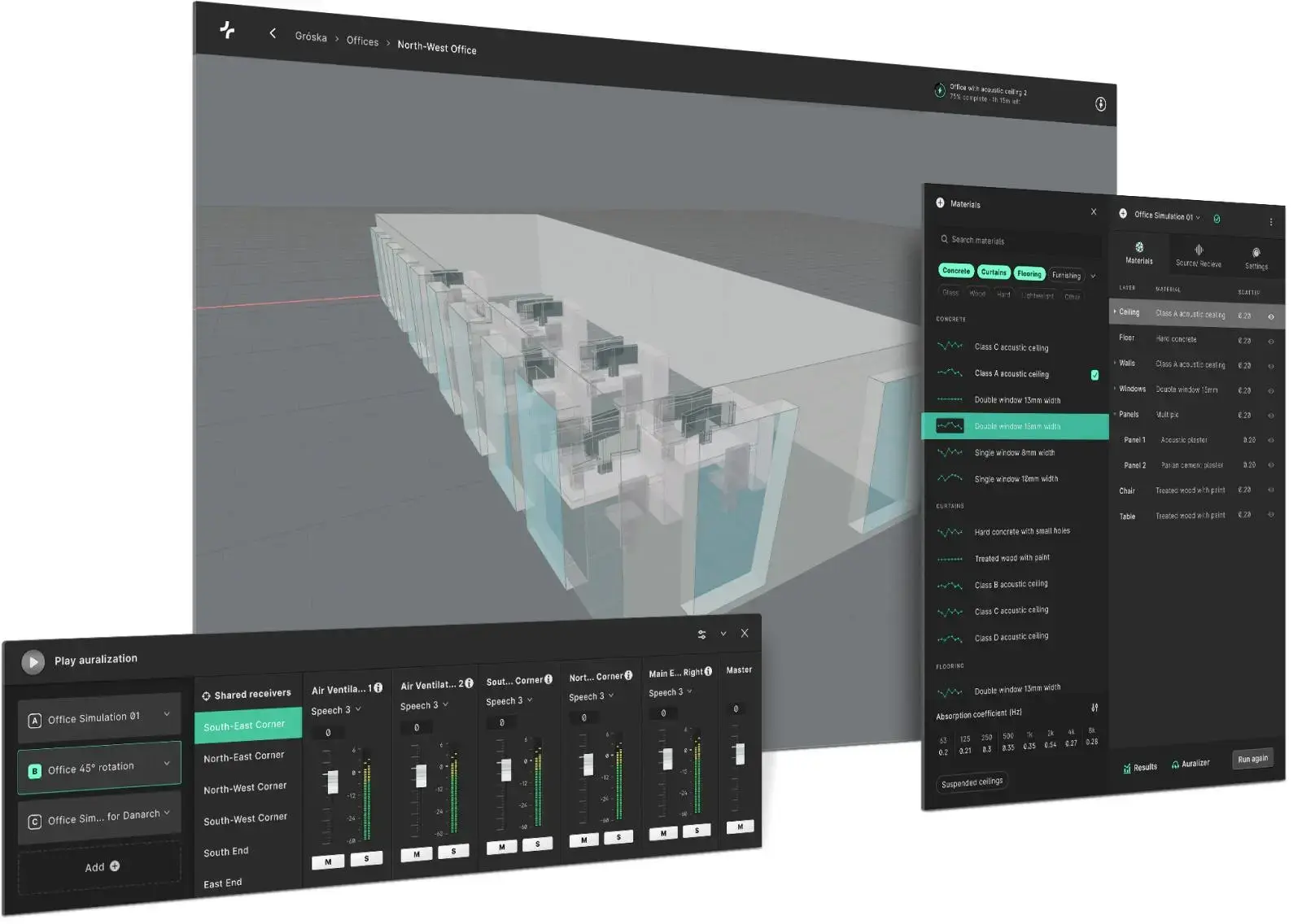

Treble Technologies社の主力製品には、音響シミュレーションと聴覚的再現(オーラライゼーション)に対応したクラウドベースの開発環境 Treble Web Application と、大規模なシミュレーションや合成音響データの生成、研究開発や機械学習パイプラインとの連携を可能にするPythonベースの開発キット Treble SDK があります。

Treble Web Application

Treble Web Applicationは、建築や製品の音響シミュレーションを行うための業界初のクラウド型プラットフォームです。現代の建築・エンジニアリングのワークフローに合わせて設計されており、波動解析(有限要素法)と幾何音響の技術を組み合わせたハイブリッドエンジンを搭載しています。これにより、幅広い周波数帯域にわたる音響シミュレーションを高精度かつ迅速に実行できます。

このプラットフォームは、建築・設計・エンジニアリング分野の専門家向けに開発されており、複雑な空間における音響の挙動をリアルに再現することが可能です。

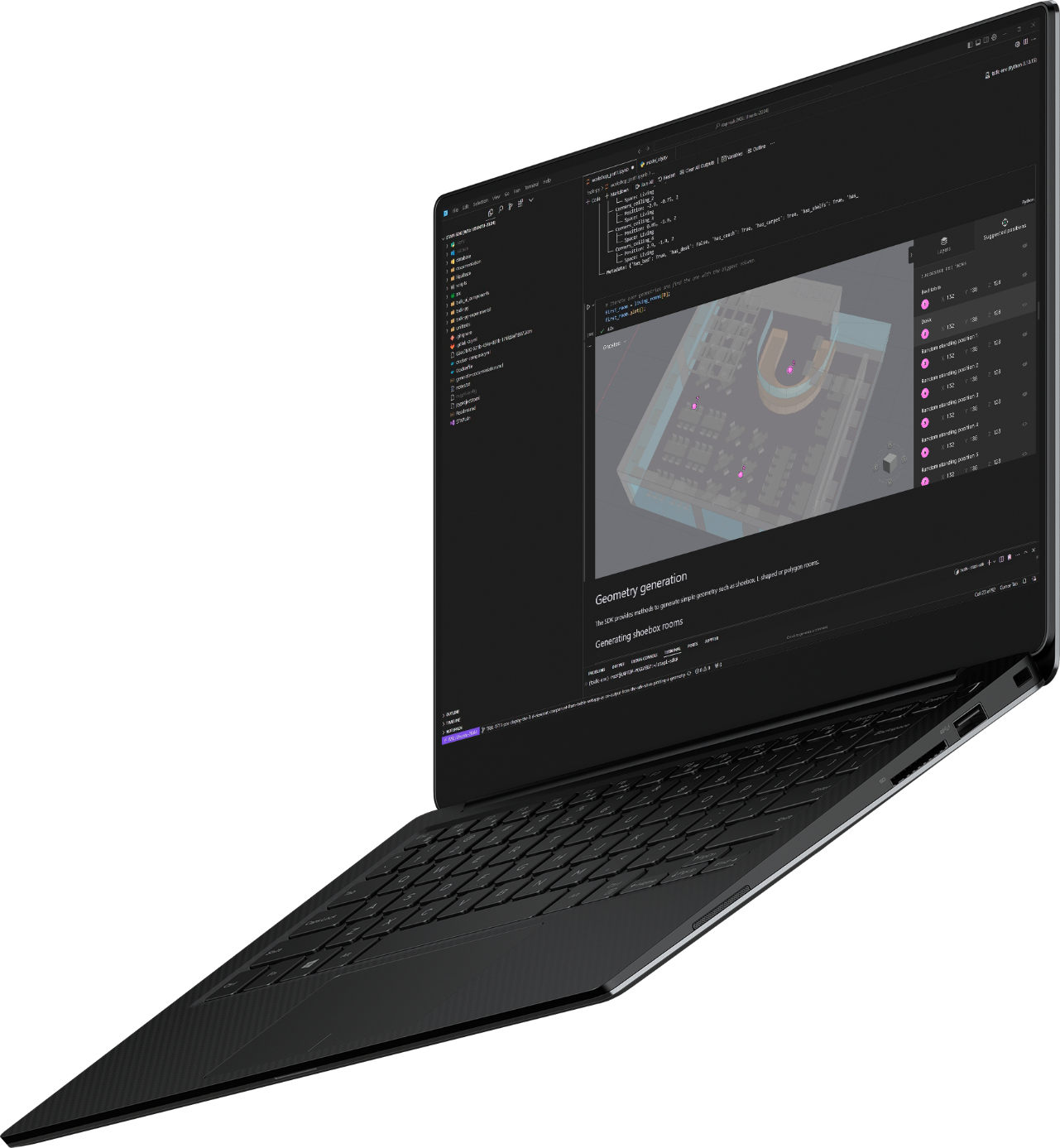

Treble SDK

Treble SDKは、Treble社 の高精度な音響シミュレーションエンジンに対する Python ベースのプログラミング・インターフェースです。大規模・高速・柔軟な連携を意識して設計されており、最先端の研究開発や音声アルゴリズムの開発、人工的な音響データ生成などを目的としています。

世界の有名テック企業は、Treble SDKを活用して、物理的に正確なスケーラブルな音響データの生成と解析の基準を築いています。

このSDKは、Treble社独自のハイブリッドシミュレーションエンジンを利用し、波の性質まで正確に再現したモノラル音響や空間音響のインパルス応答(最大32次のアンビソニックスまで対応)を生成できます。また、数千件のシミュレーションを同時に実行でき、機械学習のパイプライン、仮想試作、設計の自動化に強力に対応します。

課題

自動3Dメッシュ生成でデータ準備時間を短縮

Treble社が求めるアプリケーション要件を理解するには、まずそのワークフローを知ることが重要です。

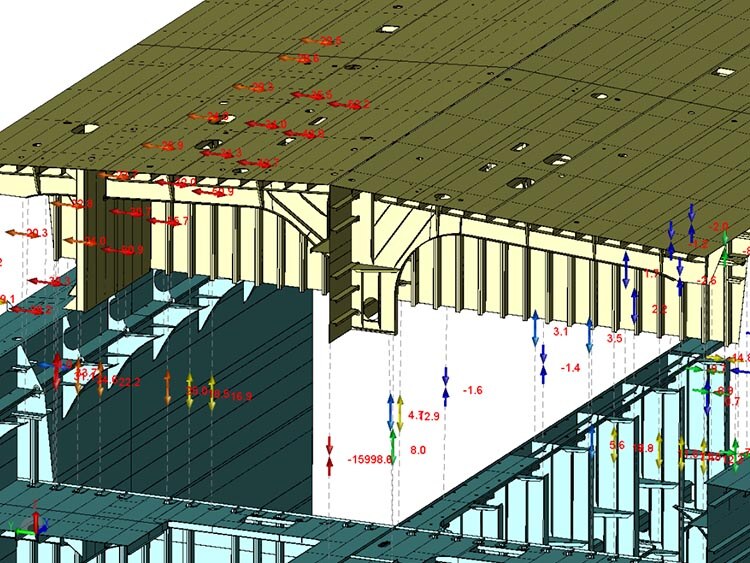

Treble Web Applicationでは、ユーザーはIFC形式やSketchUpなどの一般的なフォーマットを使って、部屋や空間の3Dモデルをインポートします。ウェブアプリ内では、音源や受音点の配置、サーフェスに対する音響材料の設定、シミュレーション・パラメーターの構成が可能です。その後は、システムが自動でジオメトリ処理、メッシュ生成、音響解析を独自のソルバーを利用して実行します。結果はレンダリング・解析・共有が可能で、共同作業者とはシンプルなウェブリンク経由ですぐに確認できます。すべての行程はブラウザベースで行われ、ローカルインストールや特別なハードウェアは不要です。

Treble SDKでは、コードベースで音響シーンを定義し、ジオメトリ、材料、音源・受音点の構成を指定したうえで、Python APIを通じてシミュレーションを実行します。SDKがクラウド上でジオメトリの前処理、メッシュ生成、解析、出力までを一貫して処理します。

Treble社は、業界で実績のあるメッシュ生成技術を求めてスペイシャルと連携しました。サーフェスおよびボリュームメッシュを生成し、それをベースに解析を行うことが必須条件であり、スペイシャルの3D Precise Meshはこのニーズを満たす最適なソリューションでした。

解決策

カスタマイズ可能な3Dモデラー、CADデータ変換、メッシュ生成ソリューション

Treble社がサーフェスおよびボリュームメッシュの生成手法を検討する中で、スペイシャルの3D Precise Meshが自社アプリケーションに迅速かつ容易に統合できることを知りました。このツールは製品に最適なだけでなく、開発・実装の工数を大幅に削減できるメリットがありました。

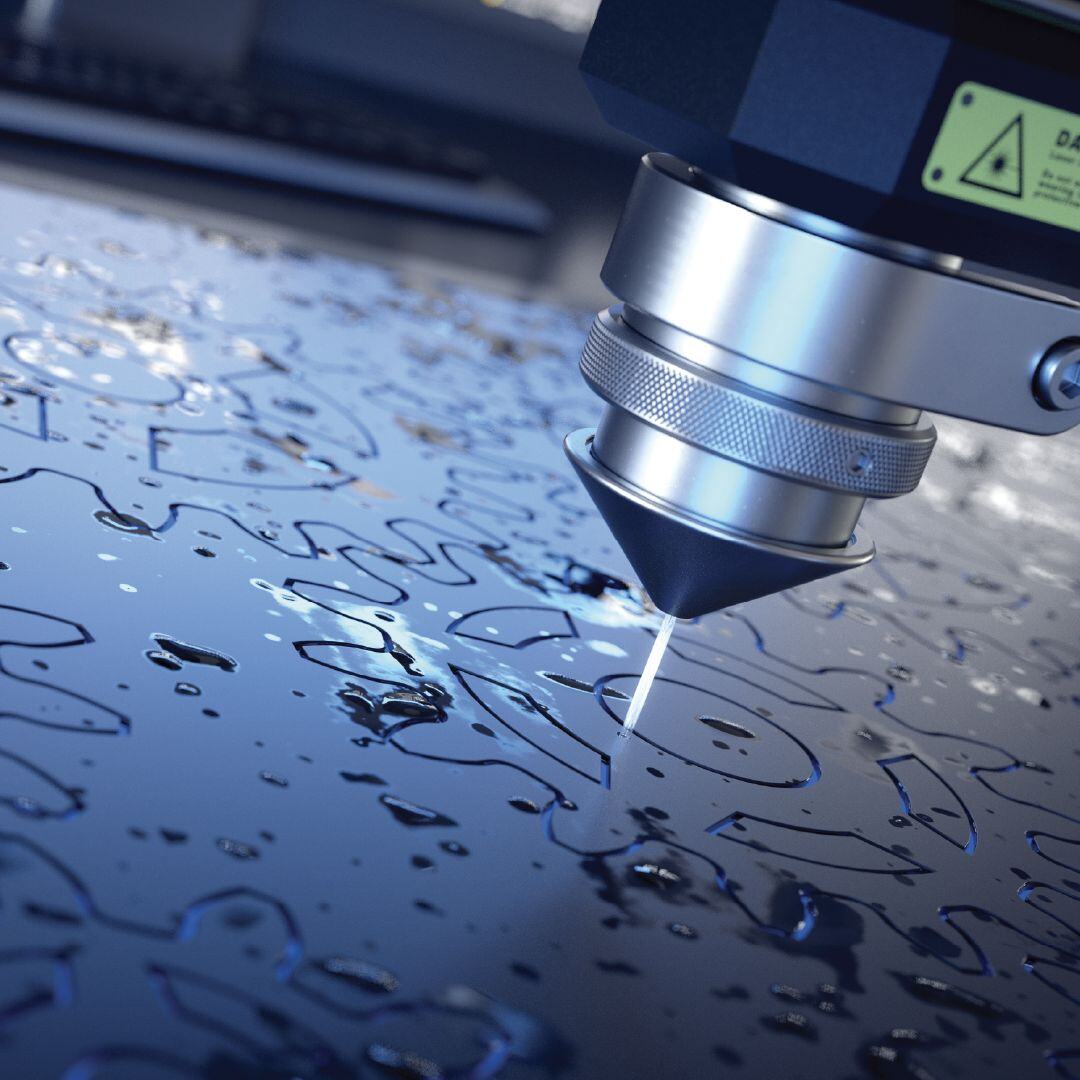

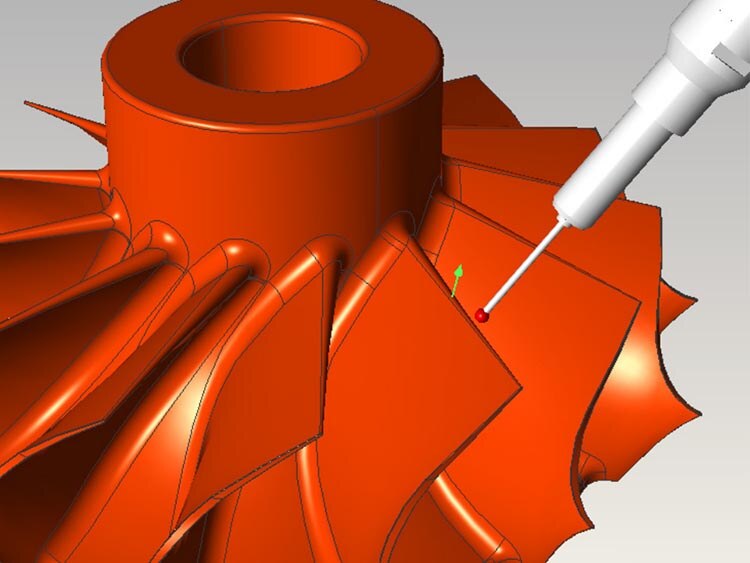

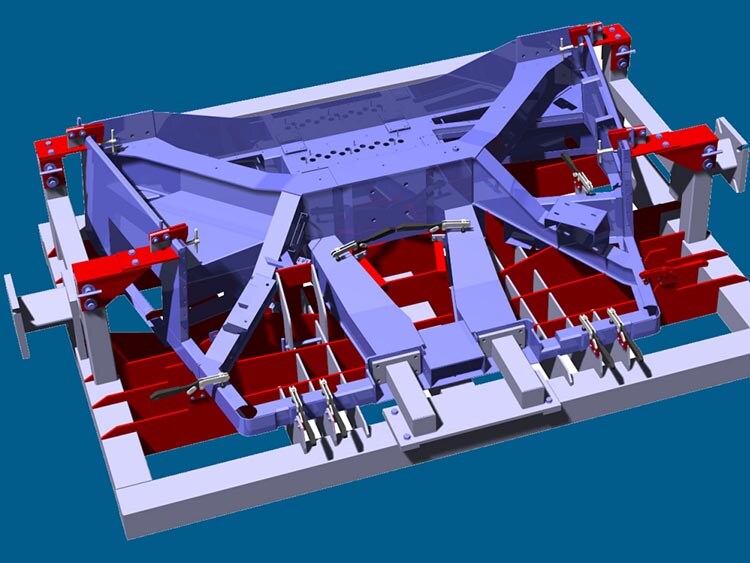

3D Precise Meshは、スペイシャルが提供する高精度な自動3Dメッシュ生成SDKです。CAEワークフローを効率化するよう設計されており、精度とシミュレーションパフォーマンスを確保しながら、細かな制御も可能です。

このSDKは、CGM Modelerや3D ACIS Modelerといった主要なモデラーとの統合に対応しており、CAD連携の自動処理機能や周期的メッシュ生成などの革新的機能により、設計プロセス全体がスムーズに進みます。

さらに、最適品質のメッシュ要素を1ステップで自動生成できるため、データ準備の工数を削減し、毎分数百万の要素を生成することも可能です。

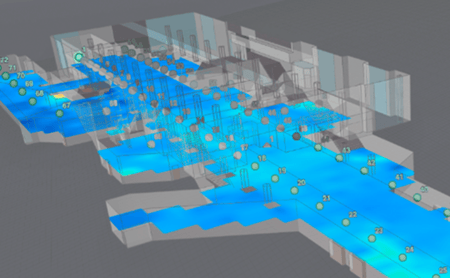

業務オペレーションの効率化

シミュレーションの処理効率が向上したことで、Treble社のビジネス全体にも直接的な効果がありました。特に「高精度な音響シミュレーションを大規模に展開できる」という、同社の核となるバリューがさらに強化されています。シミュレーションを大量かつ安定して高速処理できることは、建築設計に関わるコンサルタント支援から、機械学習用の合成音響データ生成まで、Treble社が展開するサービスの中核となっています。

スペイシャルの3D Precise Meshを活用することで、Treble社は顧客への納期を短縮し、より複雑な事例にも対応できるようになりました。性能を維持し、拡張性とスピードを両立できている点が、Treble社の差別化ポイントとなり、競合製品と比較して選ばれる理由になっています。

また、3D Precise Meshは3Dメッシュ生成のユーザー体験も向上させており、CFD(数値流体力学)解析向けメッシュ生成にかかる手間を最小限に抑え、製品設計サイクル全体をスムーズにします。その結果、Treble社はアプリケーション開発において、物理モデルやソルバー設計など、より本質的な部分に集中できる環境を整えることができました。

Trebleアプリケーションでの3D Precise Mesh活用例

Treble社は、以下のような事例で3D Precise Meshを活用しています:

- 音声強調、残響除去、音源定位などの機械学習モデルの学習・検証

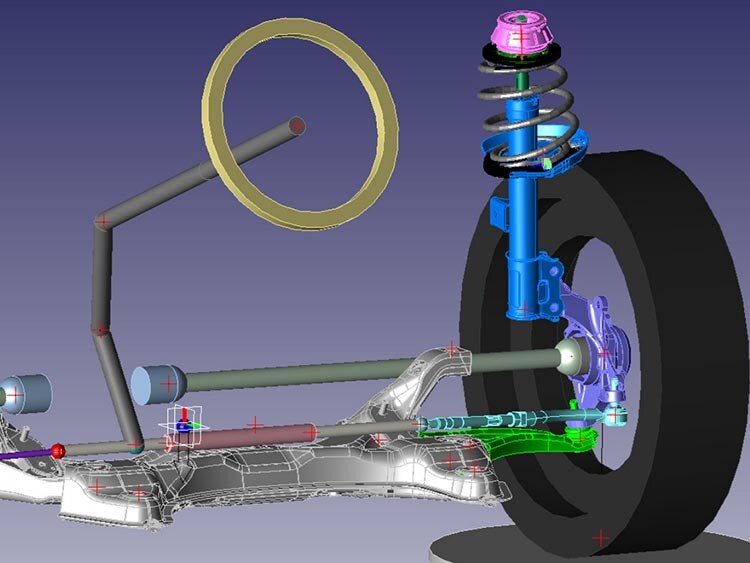

- 音声技術、AR/VRシステム、自動車オーディオにおける音響性能の評価

- シミュレーションを活用したハードウェアの最適化やジェネレーティブ・オーディオ設計

開発支援とベストプラクティスの導入

Treble社の開発チームは、3D Precise Meshの統合プロセスにおいて、スペイシャルの技術アカウントマネージャー(TAM)から技術支援を受けました。TAMとのワークショップでは、具体的な実装手順に加え、長年の経験で積み上げられたスペイシャルのベストプラクティスも共有され、効率的な統合作業を実現。

初期ステップも含めて、統合にかかった期間は約3か月です。現在もTreble社はアプリケーション向けに継続的なバージョンアップを行っており、それに伴う統合更新も随時実施。必要に応じてスペイシャルのTAMによるサポートも受けています。

重要な洞察

シミュレーション効率の大幅な改善

スペイシャルSDKを導入する以前、Treble社は学術研究ベースのオープンソースのメッシュ生成ツールを使用していました。これらは堅牢性に欠ける場合が多く、手動による調整や処理が頻繁に必要でした。しかしスペイシャルの導入により、メッシュ品質やデータ処理面で明らかな改善が見られ、シミュレーションの信頼性が向上し、ワークフローも効率化されました。

シミュレーションの効率はTreble社の顧客にとって非常に重要です。多くのユーザーは設計の反復スピードが求められる環境で作業しており、迅速で確実な実行が必須です。 3D Precise Meshの導入によって最も顕著だったのは、ボリュームメッシュ生成の効率向上であり、最大約30%の改善が見込まれています。この結果、より多くのシミュレーションを短時間で処理できるようになり、手動による調整も大幅に削減されました。

さらに、シミュレーション設定やトラブル対応などに伴う運用負荷も軽減され、処理フロー全体が安定し、拡張性も向上しています。精度と納期が重要視される市場において、この性能向上はTreble社の明確な差別化要因となっています。

スペイシャルSDKの活用により、Treble社は「大規模かつ高精度な音響シミュレーションを効率的に提供する」という本来の価値提供に集中できるようになりました。

Read More Spatial Case Studies

See how our industry-leading SDKs have helped countless businesses across several verticals. Browse

some of our other case studies below.

Treble Technologies Streamlines Simulation with Automatic 3D Meshing

Treble Technologies accelerated their simulation pipeline by integrating Spatial’s Meshing SDK, enabling faster, high-fidelity acoustic simulations at scale.

TraceParts enhances 3D Web Viewer Capabilities

TraceParts, a well-known CAD content supplier, integrates robust 3D visualization into their online 3D part viewer to enhance customer ordering experience.

Prototek Released Advanced Digital Manufacturing Quoting

Prototek IQ, empowered by Spatial components allow instant quoting for 3D models. It saves customers’ time, alleviates administrative tasks, and opens new opportunities in digital manufacturing.

-1.png)

Coreform Brings Game-Changing Simulation Software To Life

Coreform was poised to make a real impact on the CAE world. By integrating specific Spatial SDKs customized to their needs, Coreform closed the circle on its revolutionary software.

LK Metrology Future Proofed their Application

LK Metrology was on a quest to maintain precision for their Coordinate Measuring Machines. They improved core application functionality through a development partnership with Spatial.

Stäubli Elevated Their Offerings and Capabilities with Spatial's SDKs

Stäubli Robotics Suite 2022 offered optimized features for complex automation scenarios, enabled by Spatial’s CGM Modeler.

ABB's Programming Without Shutting Down Production

ABB’s Robotics Division used RobotStudio software for PC-based robot programming, boosting productivity without production shutdowns.

Dukin Co Slashed Development Costs by 50%

Dukin used 3D ACIS Modeler to focus on core technology, reducing time spent on solid modeling and accelerating new product development.

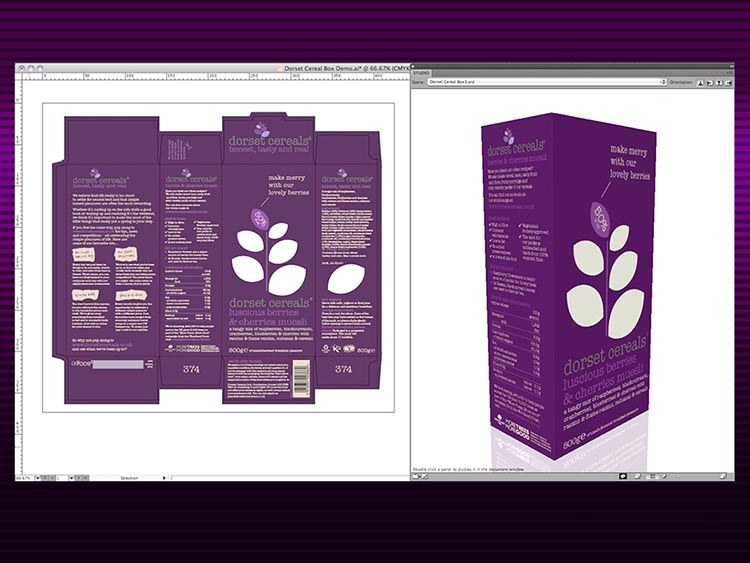

EskoArtwork Drastically Reduced Preparation of CAD Models for Downstream Use

EskoArtwork's ArtiosCAD gained 3D CAD model import functionality, maintaining competitive edge without straining in-house resources.

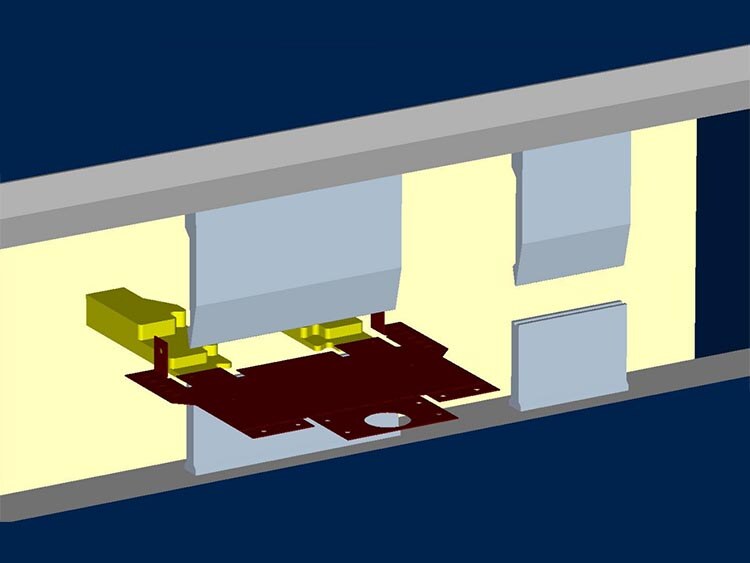

FCC Increased Production Time by 20x

A leading CAM software provider for sheet metal manufacturing used 3D ACIS Modeler for robust 3D modeling and simulation.

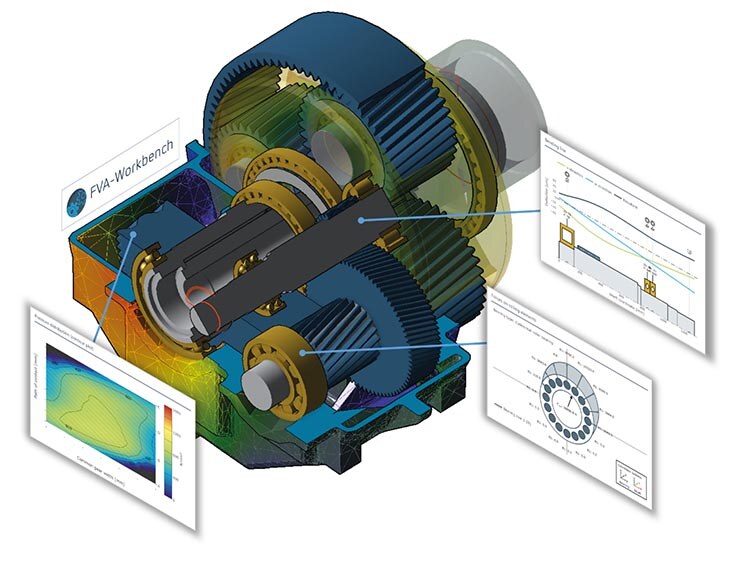

FVA Accelerated Support for New and Updated CAD Formats

FVA's solutions served the driveline industry with software capable of sophisticated simulations and detailed analyses of gearbox components.

IMSI Accelerated Time-to-Market for New Features

IMSI/Design integrated new versions of ACIS quickly, bringing a new version of TurboCAD to market every 12-15 months.

InnovMetric Eliminated Nearly 100% of Their Translation Errors

InnovMetric provided their automotive and aerospace customers with top CAD translators in PolyWorks® by selecting Spatial InterOp software.

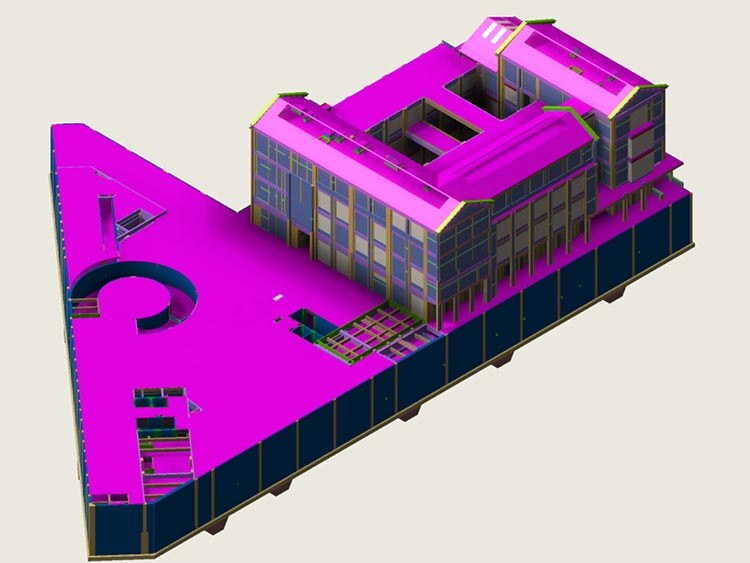

Lubansoft Boosted Design Quality and Reduced Costly Errors

Lubansoft boosted design quality and reduced errors in their BIM software by using 3D ACIS Modeler and HOOPS Visualize.

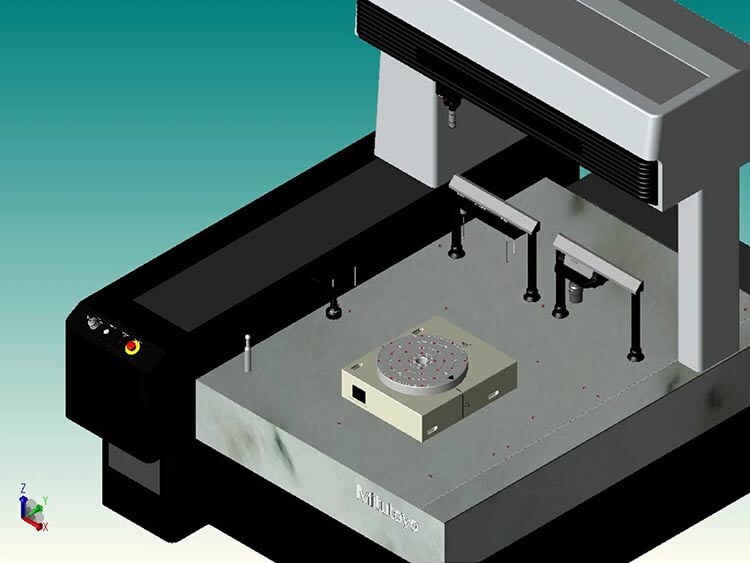

Mitutoyo Supercharged Their 3D Interop Translation

Mitutoyo broadened the use of Spatial technology to other parts of the organization, such as machine configuration.

NIS Reduced File Size of Their CAD Design Software by 30%

NIS developed next-generation building exterior and garden design CAD software using 3D ACIS Modeler and HOOPS.

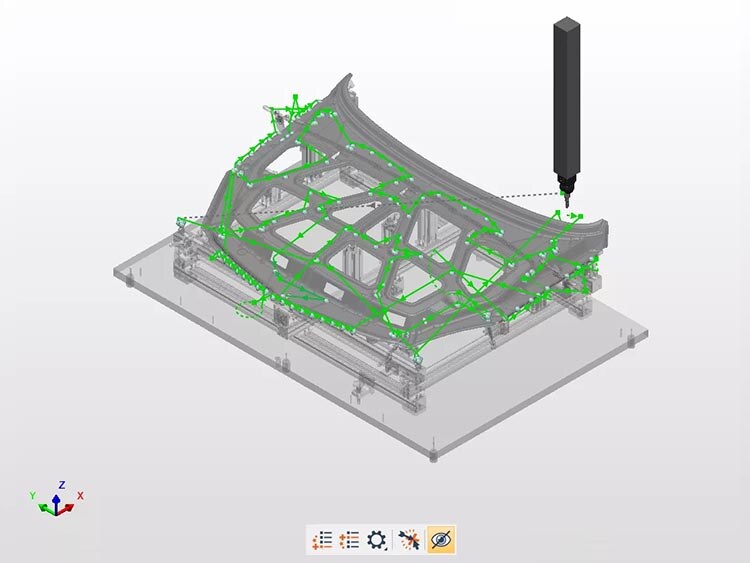

Renishaw Drastically Reduced the Need for STL File Healing

Renishaw integrated Spatial SDKs into QuantAM 2017, enabling users to build parts correctly the first time, preserving original design intent.

SAMIN Chose Spatial's ACIS 3D Kernel Instead of Parasolid

SAMIN became first to market in 2008 with a 3D accuracy control system that met the high standards of the Asian shipbuilding market using Spatial components.

Virtual Motion Cut Development Time by 50%

Virtual Motion integrated the 3D ACIS modeling engine and leveraged AGM and HOOPS to accelerate DAFUL software development, bringing a new product to market quickly.

XEOMETRIC Accelerated Blending and Precise Hidden Line Removal

XEOMETRIC's 2D/3D construction planning and mechanical engineering software gained advanced functionality with 3D ACIS Modeler and 3D InterOp.

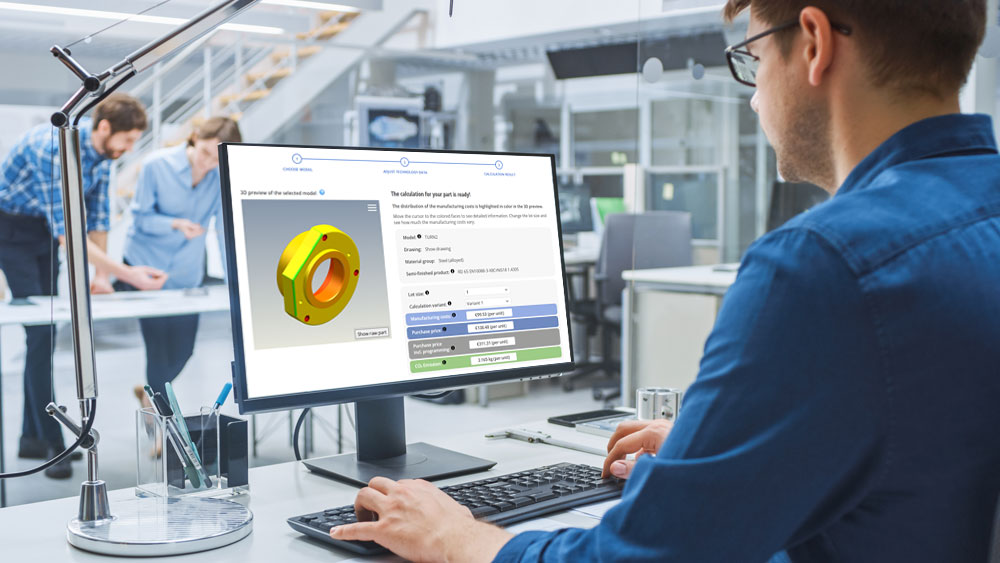

How Simus Systems Uses 3D InterOp to Enable Cloud-Based Costing and CAD Classification

Simus Systems needed a CAD format interface to move their data processing and costing software to the cloud.