摘要

InnovMetric希望其3D点云处理软件能够提供与大型软件公司相同的CAD导入功能。他们的首要目标之一是实现近乎100%无差错的CATIA v5文件导入。

InnovMetric最终选择了Spatial公司的3D InterOp软件,因其具备高端CAD转换器,尤其擅长完美兼容CATIA v4和v5数据交换。此外,Spatial频繁的版本更新与服务包支持,使InnovMetric能够持续保持竞争优势。

我们很高兴能与Spatial合作。我们认为其InterOp翻译器对我们的产品开发来说是一笔巨大的财富,我们期待着使用其翻译器来改善PolyWorks的未来。

公司

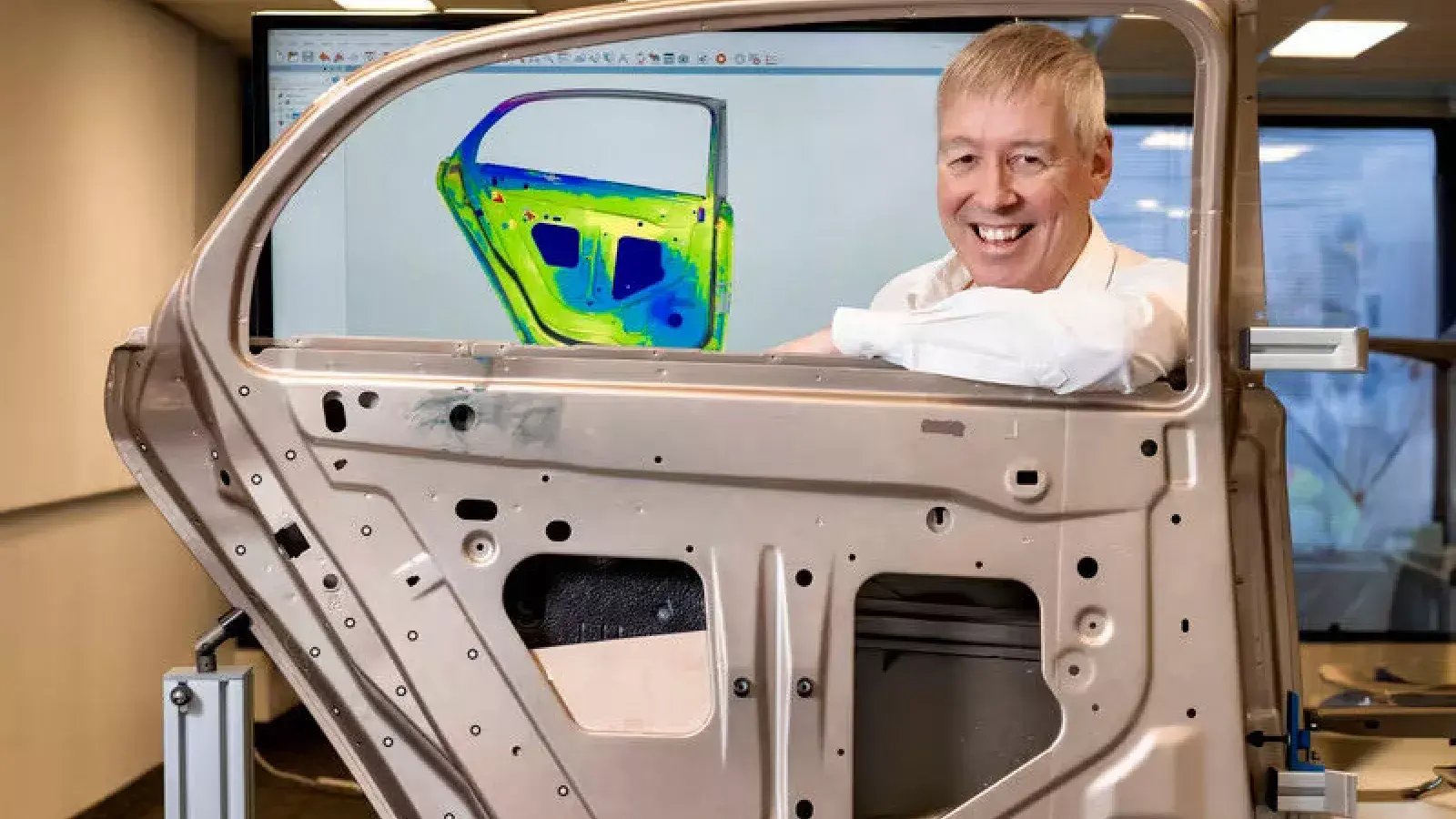

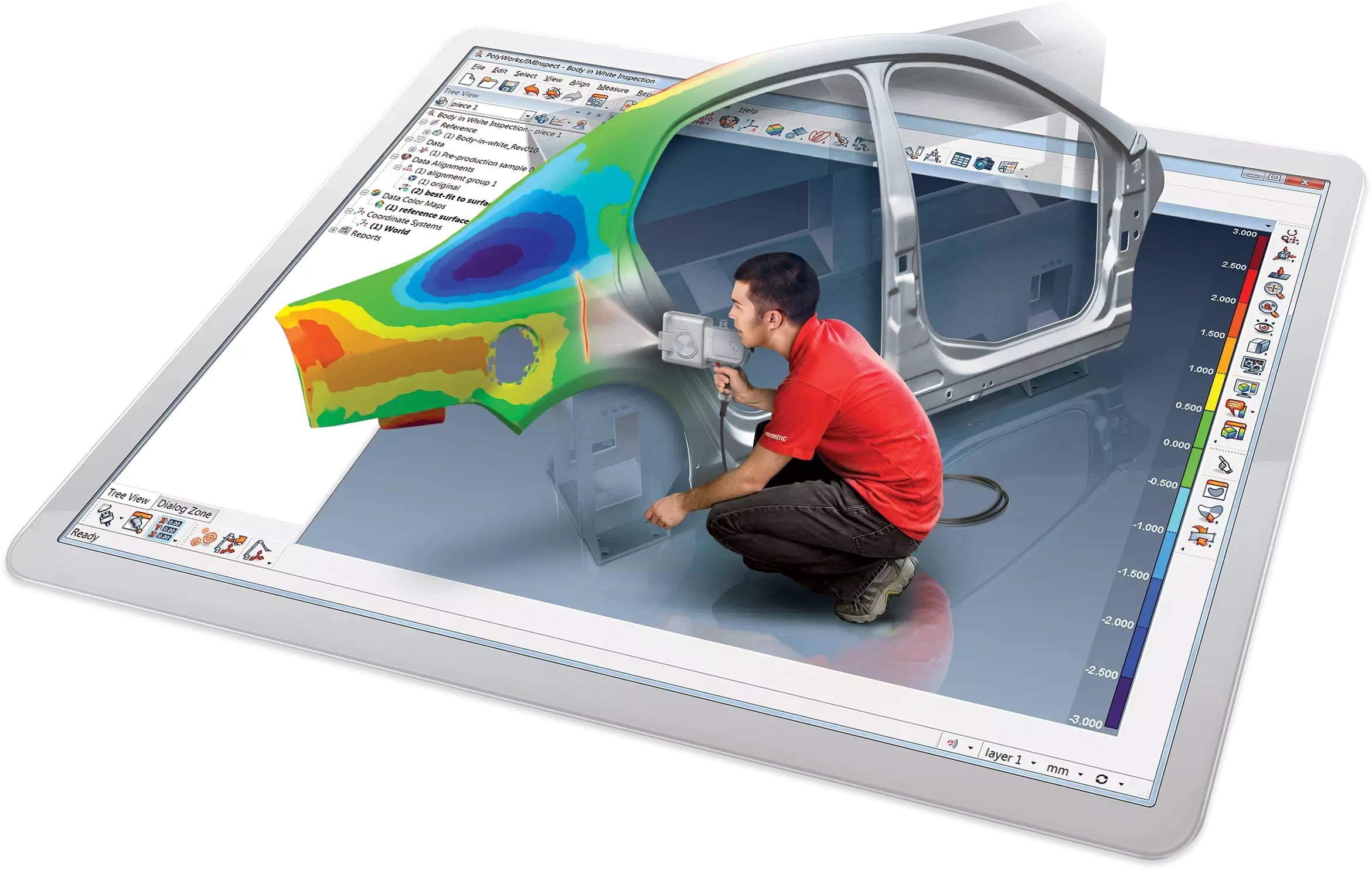

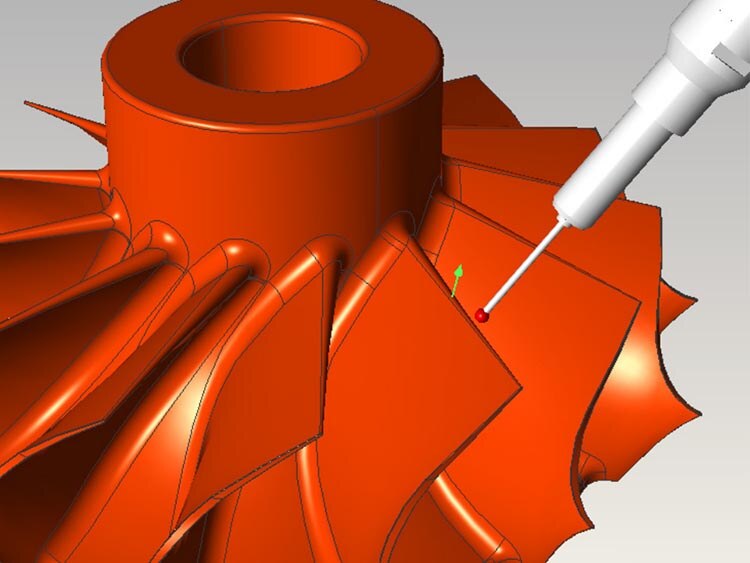

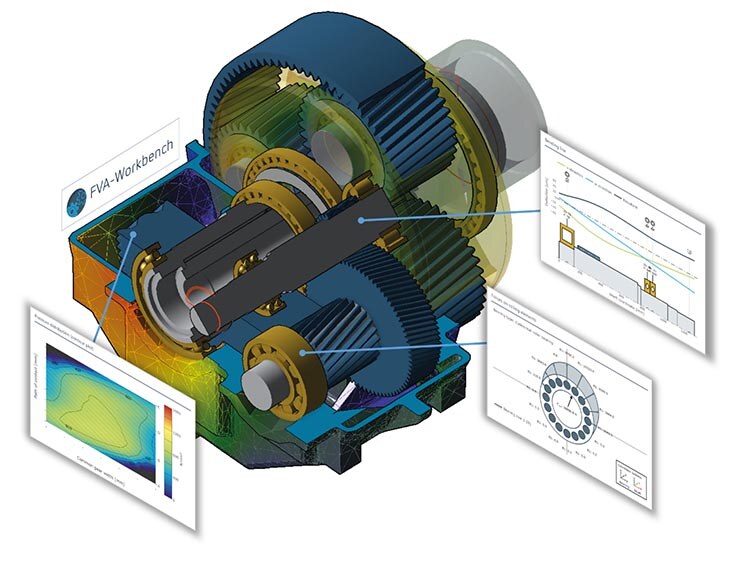

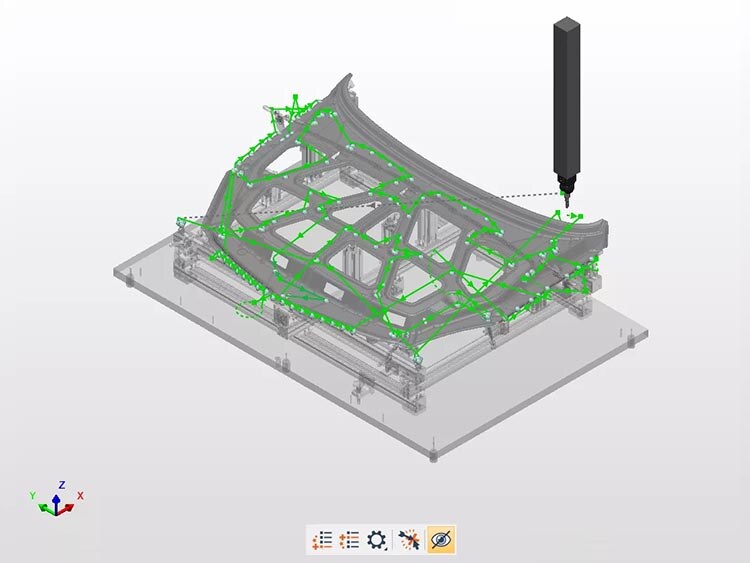

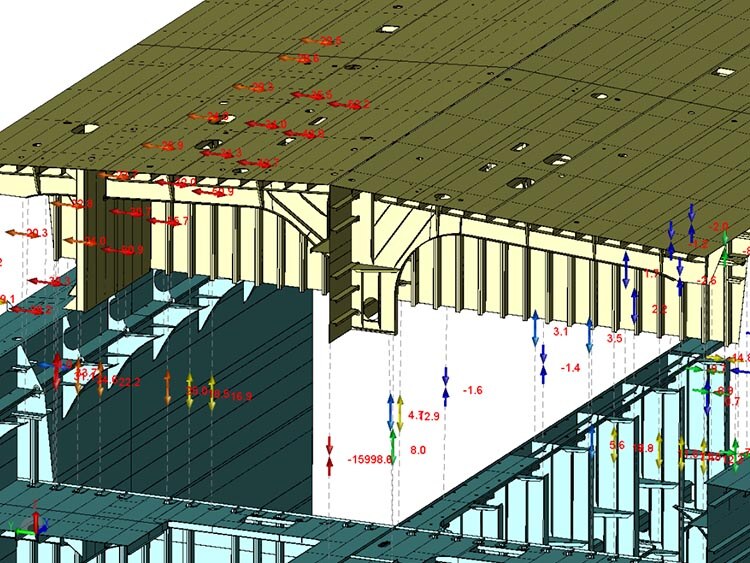

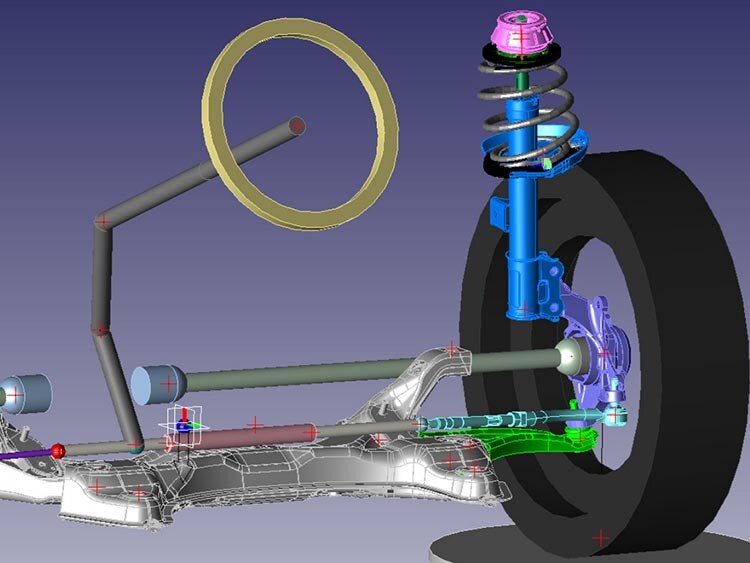

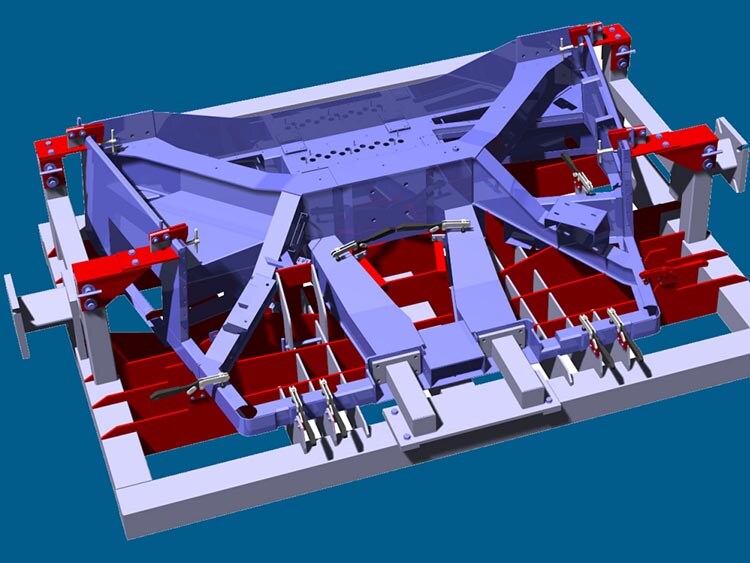

InnovMetric公司(InnovMetric Software Inc.)成立于1994年,是业界率先开发将高密度3D数字化设备转化为真正计量仪器的软件先驱。作为一家私营企业,InnovMetric旗下的PolyWorks®检测与建模解决方案已在全球30多个国家得到日常应用,为宝马、波音、戴姆勒-克莱斯勒、福特、保时捷和丰田等客户提供市场上最全面、精准且可靠的3D点云处理软件解决方案。

挑战

InnovMetric希望在其产品中提供与大型软件公司相同的CAD导入功能。要在汽车和航空航天行业保持竞争力,公司必须实现近乎100%无差错的CATIA v5文件导入。由于市场上已有成熟的商业解决方案,若自行开发数据交换功能对InnovMetric而言并不经济高效。因此,公司最终选择了一款性价比优异、性能卓越的第三方工具,以满足其严苛的技术要求和品质期望。

解决方案

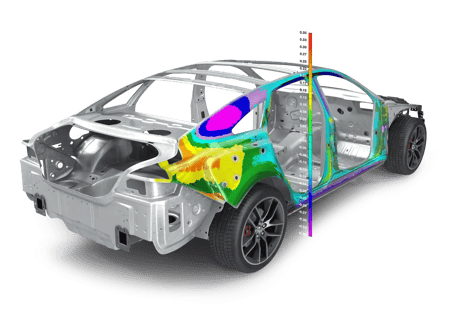

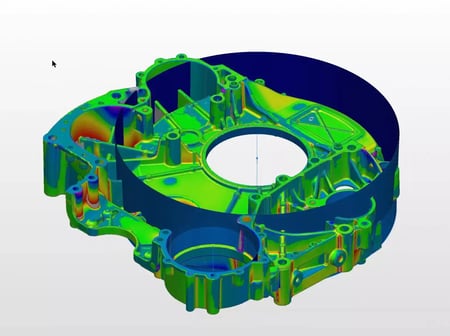

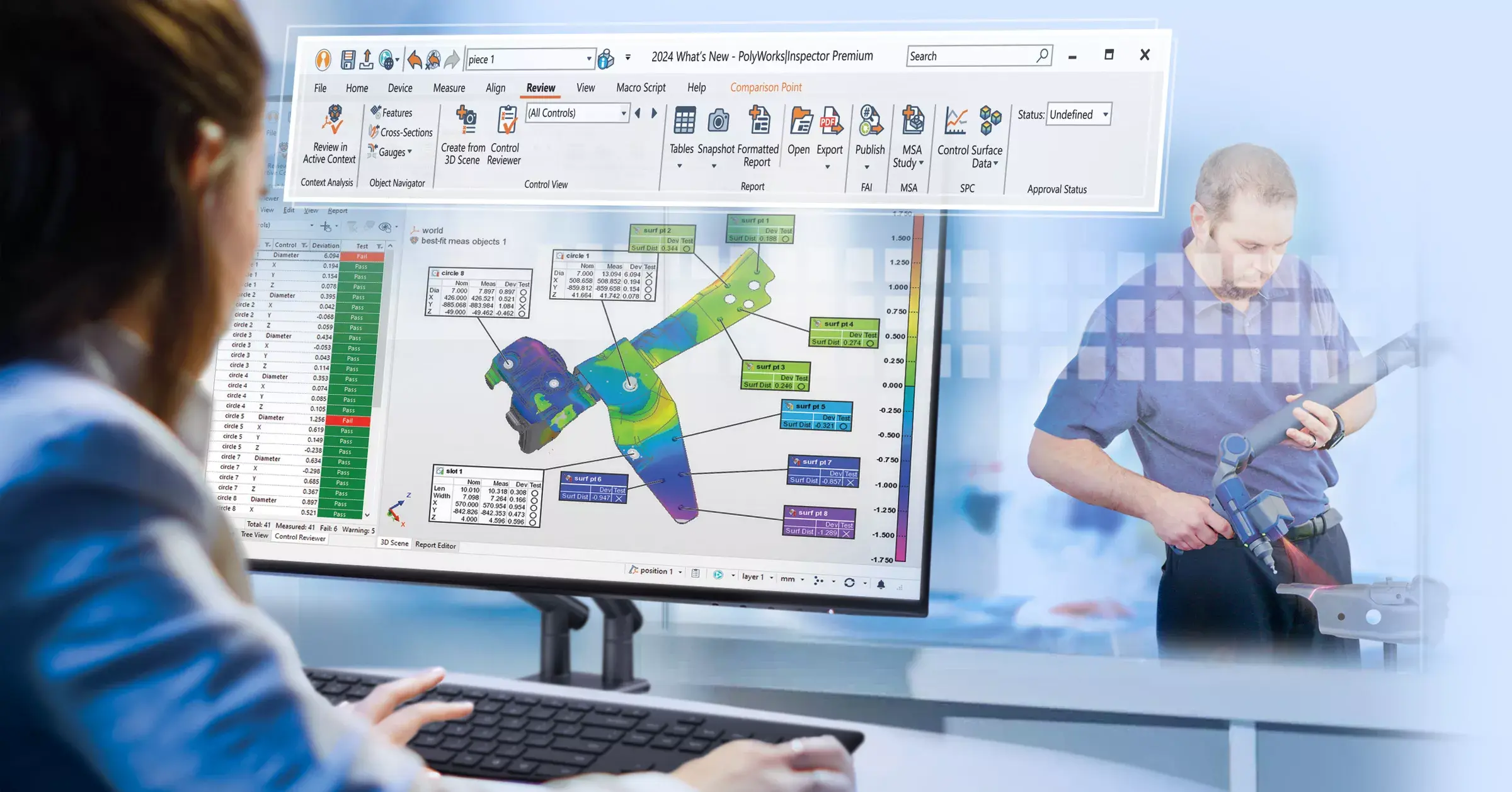

2002年,InnovMetric在Spatial公司的3D InterOp转换器技术中找到了答案,并持续将其集成至PolyWorks软件中。Spatial的InterOp组件使其具备高端CAD导入功能,显著提升了在汽车和航空航天领域头部客户中的渗透率。"我们很自然地选择了Spatial",InnovMetric总裁马克·苏西表示。通过Spatial的InterOp转换器,InnovMetric获得了稳定且持续更新的高端CAD转换技术,公司非常放心将这些技术提供给客户。InnovMetric的客户期望获得近乎完美的无差错文件导入体验,并确保文件内容的完整呈现。

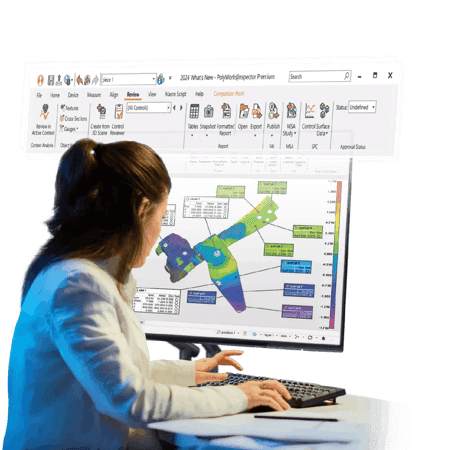

Spatial的3D InterOp转换器使InnovMetric客户能轻松将先进的3D数据互操作性功能集成到各类应用中,包括:使用3D信息的CAD/CAM/CAE应用程序;PDM/PLM协同系统等数据管理系统;以及可视化应用程序。"Spatial的CAD转换技术已臻成熟——这是款极其出色的产品",苏西强调道。在将InterOp库初步集成至PolyWorks后,得益于Connect API接口,如今InnovMetric新增转换器的集成时间已缩短至不足一小时。

成果

InnovMetric选择收购Spatial的3D InterOp技术,从而避免了自主开发该技术可能面临的资源消耗、经济成本及上市周期等挑战。"我们自始至终与Spatial共同推进该库的开发,并欣慰地看到我们的建议与需求持续体现在新版本和服务包中。"Spatial灵活的商业模式完美适配InnovMetric这类规模虽小却需服务全球顶尖企业的公司。

凭借Spatial的技术支持,InnovMetric在CAD转换器市场极具竞争力。其核心客户群的销售业绩主要来自UG或CATIA转换器,部分客户甚至会同时采购CATIA v4和v5版本。该公司最大的竞争优势在于:与逆向工程转换器不同,Spatial的CATIA v5转换器直接调用原生CATIA库——这项被几乎所有汽车制造商采用的技术。Soucy补充道,该技术的卓越稳定性可确保近乎零瑕疵的数据导入,完全规避转换错误。

主要观点

解决方案

得益于Connect API,InnovMetric仅用不到一小时便成功集成3D InterOp。Spatial频繁的版本更新与服务包发布,持续为InnovMetric保持竞争优势提供支撑。阅读更多Spatial案例研究

了解我们业界领先的 SDK 如何帮助多个垂直领域的无数企业。浏览下方的其他案例研究。

Stäubli借助Spatial SDK提升产品与能力

Stäubli Robotics Suite 2022在Spatial的CGM Modeler支持下,为复杂自动化场景提供了优化功能。

Prototek推出先进数字化制造报价系统

Prototek IQ借助Spatial组件,实现了对3D模型的即时报价,节省客户时间,减轻管理负担,并为数字化制造开辟新机遇。

-1.png)

Coreform推出革命性仿真软件

Coreform决心在CAE领域产生真正影响。通过集成定制化的Spatial SDK,Coreform完善了其革命性软件。

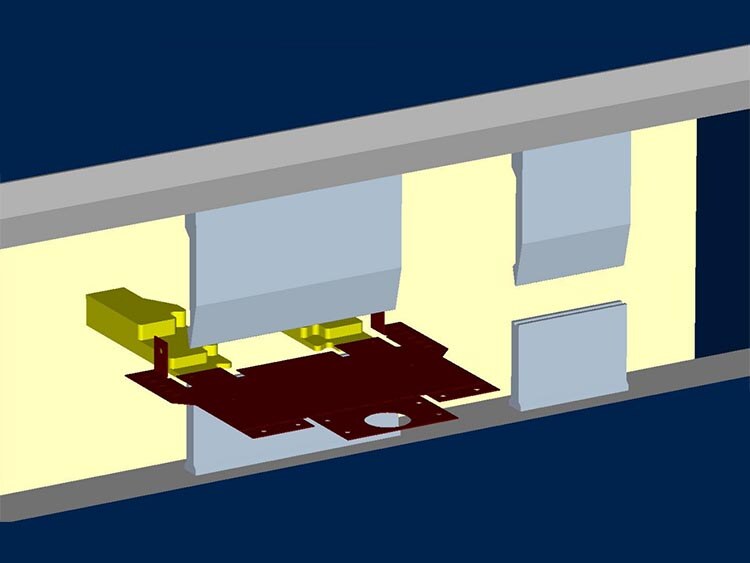

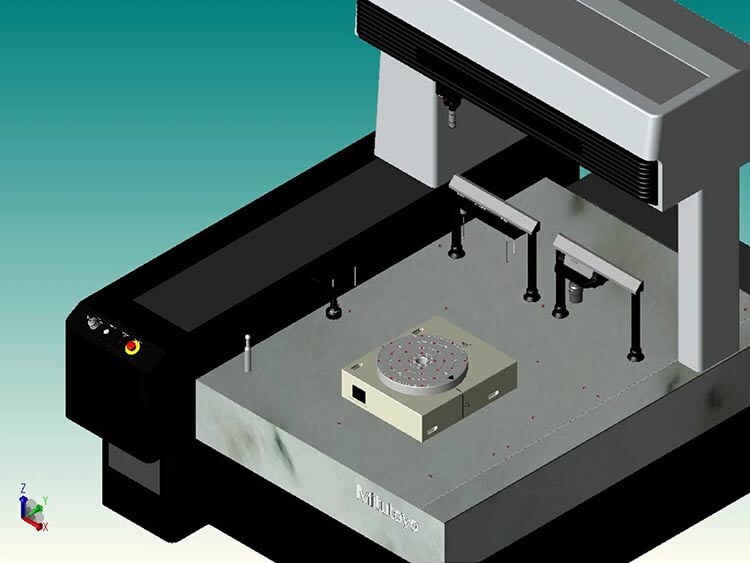

LK Metrology确保应用未来无忧

LK Metrology致力于保持其坐标测量机的精度。通过与Spatial的开发合作,他们提升了核心应用功能。

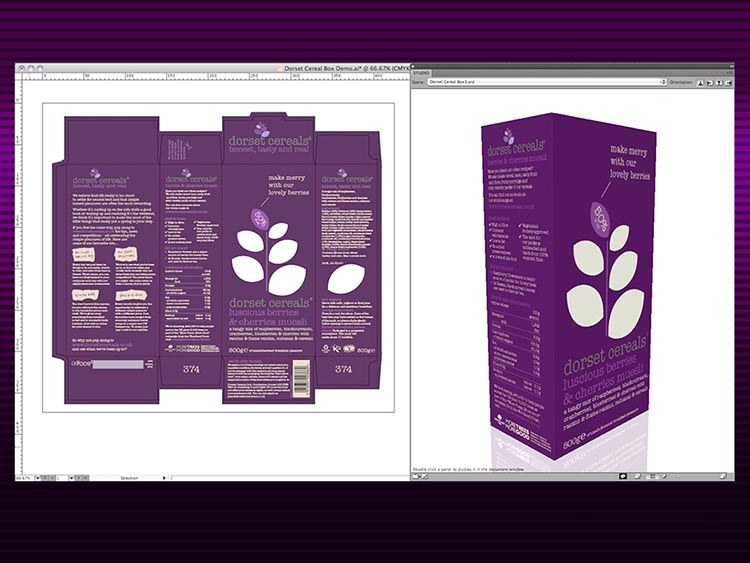

EskoArtwork大幅减少下游CAD模型准备

EskoArtware的ArtiosCAD新增3D CAD模型导入功能,保持竞争优势且不增加内部资源压力。

InnovMetric几乎消除100%翻译错误

InnovMetric通过选择Spatial InterOp软件,为汽车和航空航天客户提供PolyWorks®中的顶级CAD翻译器。

Lubansoft提升设计质量,减少昂贵错误

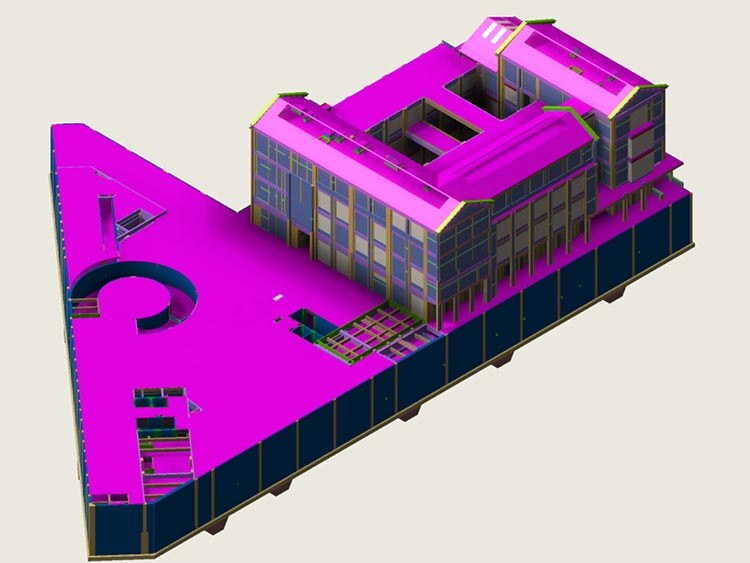

Lubansoft使用3D ACIS Modeler和HOOPS Visualize提升BIM软件设计质量,减少错误。

Renishaw大幅减少STL文件修复需求

Renishaw将Spatial SDK集成至QuantAM 2017,使用户首次即可正确构建零件,保留原始设计意图。

SAMIN选择Spatial的ACIS 3D内核而非Parasolid

SAMIN于2008年率先推出符合亚洲造船市场高标准的3D精度控制系统,使用了Spatial组件。

Virtual Motion缩短50%开发时间

Virtual Motion集成3D ACIS建模引擎并利用AGM和HOOPS加速DAFUL软件开发,快速推出新产品。

XEOMETRIC加速混合与精确隐藏线移除

XEOMETRIC的2D/3D建筑规划与机械工程软件通过3D ACIS Modeler和3D InterOp获得高级功能。

TraceParts增强3D网页查看器功能

知名CAD内容供应商TraceParts在其在线3D零件查看器中集成了强大的3D可视化功能,以提升客户订购体验。

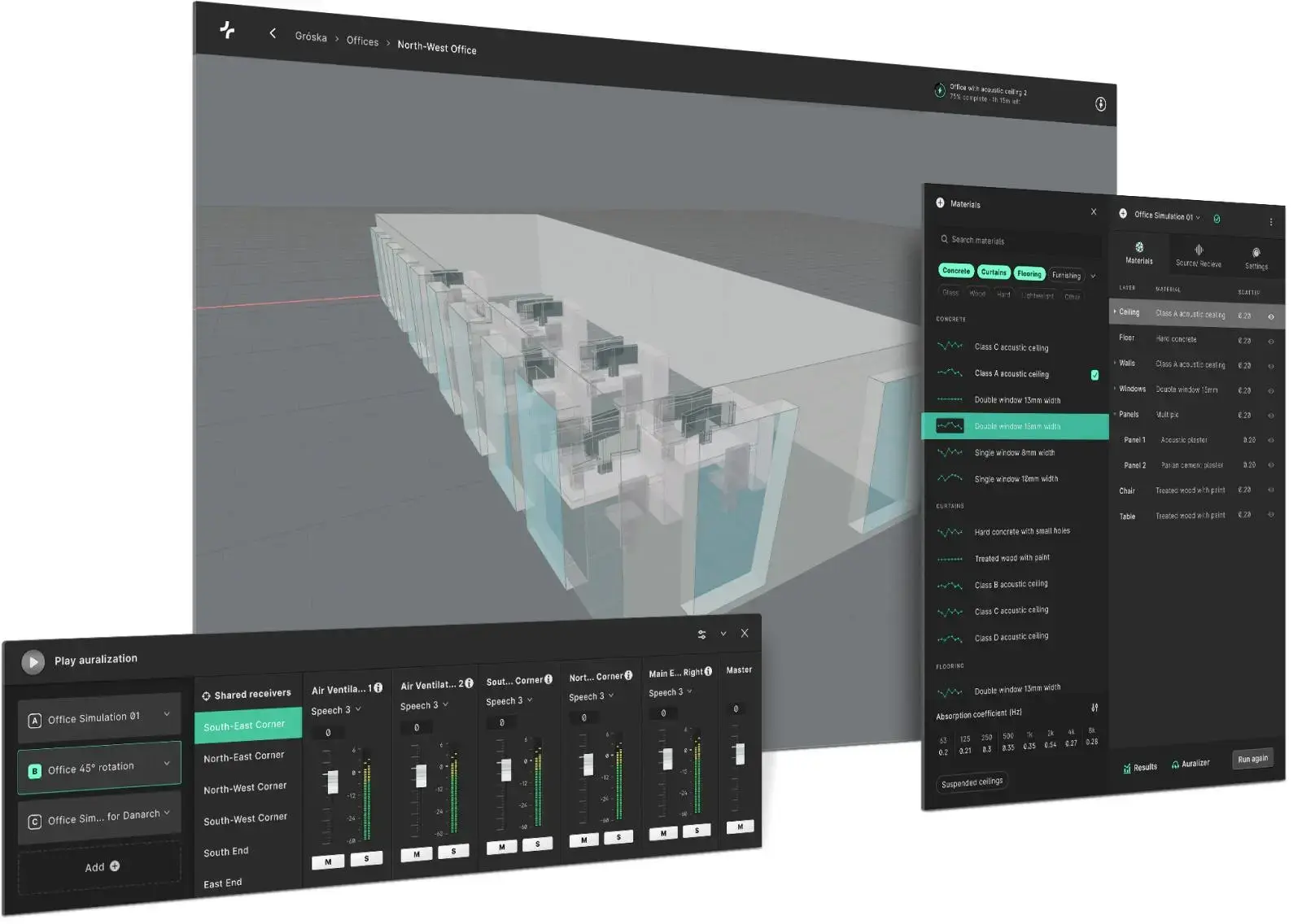

Treble Technologies通过自动3D网格化简化仿真

Treble Technologies通过集成Spatial的Meshing SDK加速仿真流程,实现更快、高保真的大规模声学仿真。